Rubber Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

Custom Rubber Bellows

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

Silicone Rubber Bellows

High Durability

Shock Absorption

Heat Resistance

Enhanced Insulation

Reliable Performance

Bellow Boot

Precision Profiles

Durable Materials

Chemical Resistance

Custom Shape & Size

Silicone Bellows

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

Flexible Bellows

Precise Fit

Durable Material

Customizable Shapes

Leak-Proof Sealing

- Home

- Bellows Location

Choosing the Right Industrial Rubber Bellows Material

Industrial Silicone Bellows play a perilous role in defensive machinery, absorbing movements and enhancing sturdiness across a wide range of applications. The recital of a bellows largely depends on the substantial used, which determines its resistance to temperature, chemicals, pressure, and environmental conditions.

Among the commonly used options are EPDM Bellows, Silicone Bellows, Hypalon Rubber Bellows, Neoprene Rubber Bellows, Butyl Rubber Bellows, Nitrile Bellows, Natural Rubber Bellows, Polyurethane Bellows, and PVC Rubber Bellows. Understanding the strengths and limitations of each type is indispensable for selecting the perfect fit for your machine.

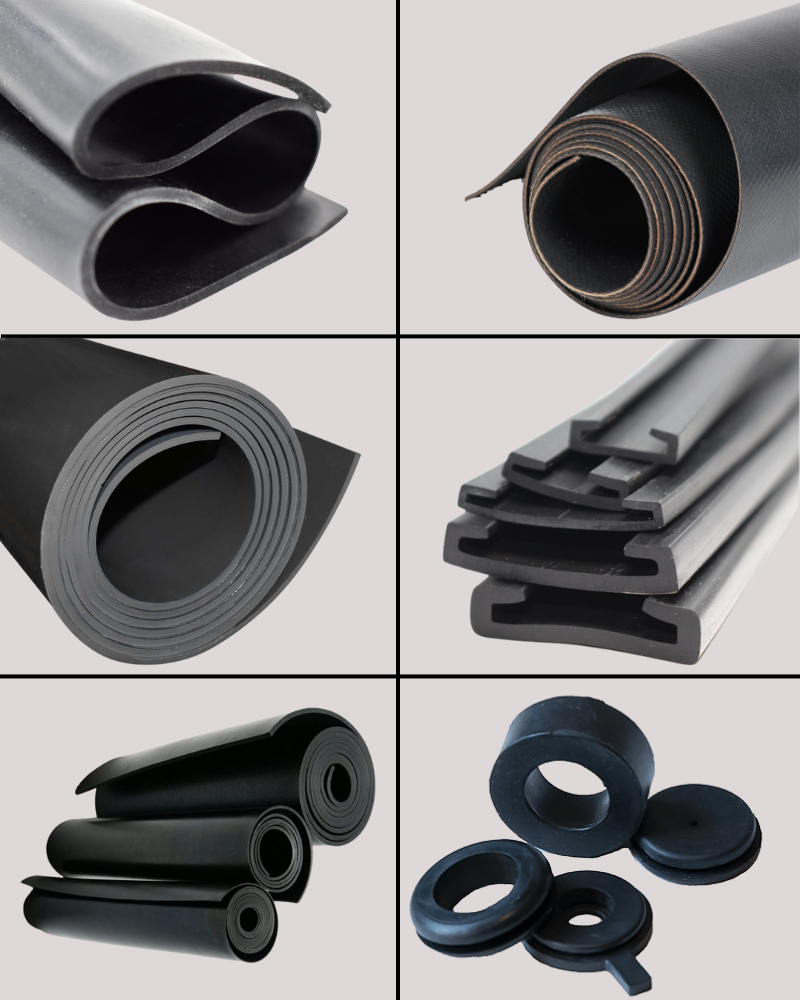

Variety of Material Choices

EPDM Bellows

maintain elasticity even at high temperatures and are known for their brilliant electrical insulation properties. This makes them ideal for HVAC systems, automotive, and chemical processing.

Silicone Bellows

Silicone Bellows are favored wherever high temperature stability and food-grade compatibility are required. This makes them perfect for the medical and food processing industries.

Hypalon Rubber Bellows

Hypalon Rubber Bellows are designed for atmospheres involving aggressive chemicals, ozone exposure, and extreme weather conditions. Hypalon is predominantly strong in resisting acids, alkalis, and oxidizing situations.

Neoprene Rubber Bellows

Neoprene Rubber Bellows are multi-purpose bellows due to their balanced recital across temperature, oil resistance, and weather protection. They are commonly used in HVAC systems, pumps, automotive, and marine applications.

Butyl Rubber Bellows

Butyl Rubber Bellows are exceedingly valued for their brilliant gas impermeability. Industries with gases, vacuum systems, and high-temperature steam often prefer butyl for its sealing efficiency.

Nitrile Bellows

Nitrile Bellows (NBR bellows) are dedicated to applications involving oils, greases, and petroleum-based fluids. This makes them the top choice for engines, fuel management equipment, oil refineries, and industrial hydraulics.

Natural Rubber Bellows

Natural Rubber Bellows are known for their incomparable elasticity, high tensile strength, and shock absorption capabilities. This makes them suitable for machinery requiring greater vibration control, such as heavy machines and compressors.

Polyurethane Bellows

Polyurethane Bellows are preferred in submissions involving extreme wear, abrasive particles, or high power-driven stress. Their robustness and elasticity outperform most other elastomers.

PVC Rubber Bellows

PVC Rubber Bellows offer a lucrative solution for light-duty applications. These bellows are a good option for ventilation systems, automotive parts, and general industrial use.

How to Choose the Right Type of Bellows?

Selecting the right bellow depends on several factors:

- Temperature Range: High heat applications require silicone or EPDM; low friction and moderate temperatures may suit PVC or natural rubber.

- Chemical Exposure: Hypalon and nitrile excel in exacting chemical environments.

- Oil & Fuel Contact: Nitrile is the best option.

- Environmental Conditions :EPDM is ideal for open-air use due to its weather resistance.

- Mechanical Stress: Polyurethane is chosen when abrasion and impact confrontation are essential.

- Cost Considerations: PVC and natural rubber bellows provide cost-effective solutions for average applications.

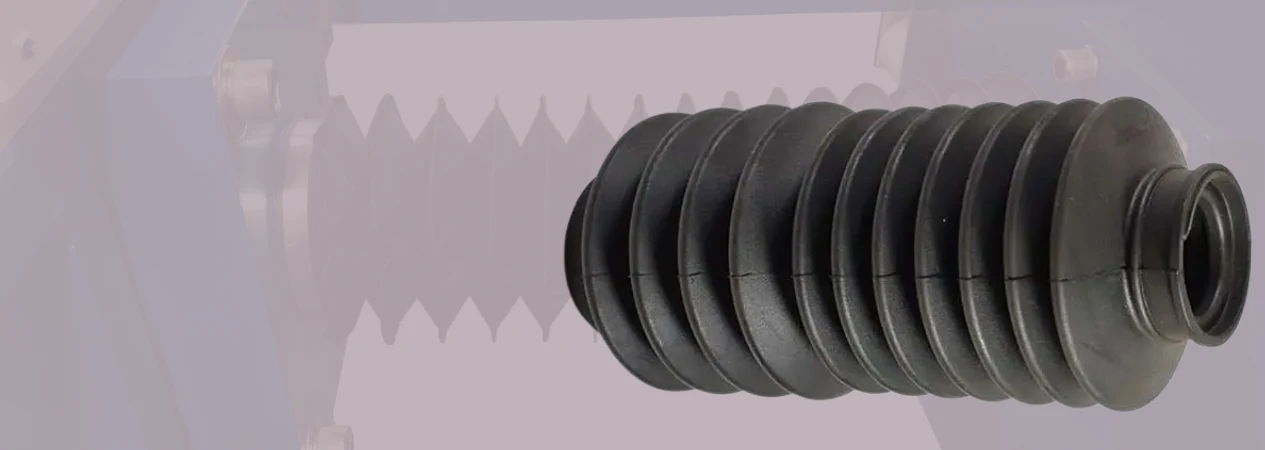

High-Performance Rubber Bellows

Our rubber bellows are designed to protect sensitive mechanical parts from dust, moisture, chemicals, and extreme temperatures. They offer excellent flexibility, durability, and long operational life across various industries including automotive, industrial machinery, and OEM applications.

Our rubber bellows are designed to protect sensitive mechanical parts from dust, moisture, chemicals, and extreme temperatures. They offer excellent flexibility, durability, and long operational life across various industries including automotive, industrial machinery, and OEM applications.

Our rubber bellows are designed to protect sensitive mechanical parts from dust, moisture, chemicals, and extreme temperatures. They offer excellent flexibility, durability, and long operational life across various industries including automotive, industrial machinery, and OEM applications.

GET A QUOTEConclusion

Each type of industrial rubber bellow offers its own set of strengths, making it important to match the material with your application�s specific requirements. Whether you need the heat resistance of Silicone Bellows, the durability of EPDM Bellows, the chemical resistance of Hypalon Rubber Bellows, or the abrasion strength of Polyurethane Bellows, choosing the right one ensures longer service life, better performance, and reduced maintenance costs. By understanding the unique characteristics of each material, industries can make smarter, more cost-effective decisions for their machinery and equipment. Looking for reliable bellows for your application? Reach out at (647) 294-5240 or info@customrubberbellows.com

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.