Custom Molded

Seals & Gaskets

Precise Fit

Durable Material

Customizable Shapes

Leak-Proof Sealing

- Home

- Custom Molded Seals And Gaskets

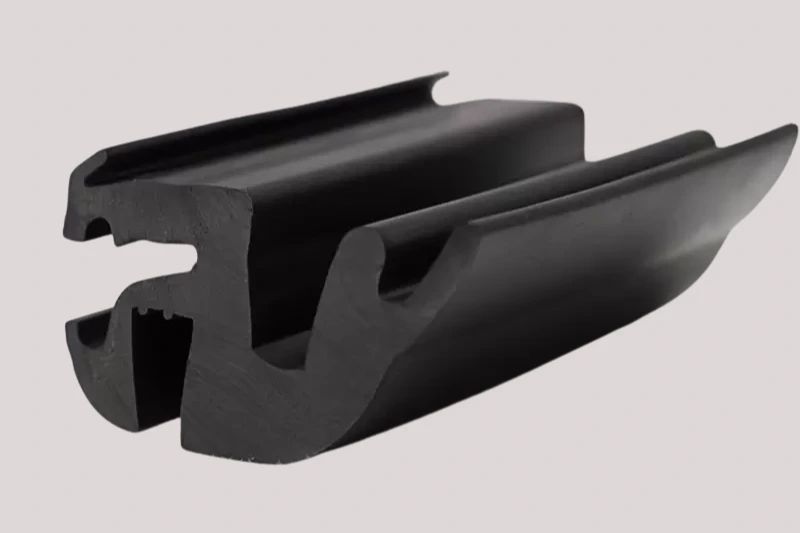

Custom Molded Seals and Gaskets for Every Application

In the world of sealing solutions for heavy industry custom molded seals and gaskets play a vital role in keeping reliability, and resilience high across many applications. Rubber gaskets and seals, crucial for industries like automotive, aerospace, healthcare, and heavy machinery, are vital for preventing leaks, dampening vibrations, and withstanding tough conditions.

Rather than using generic options, opting for custom-molded rubber gaskets and seals allows for precise fit and performance tailored to your exact requirements. This customized approach enables optimization for particular industries, which can lead to greater efficiency, fewer disruptions, and enhanced safety.

A manufacturer specializing in custom rubber seal gaskets can offer solutions that perfectly match unique requirements by carefully selecting the right material, size, and design. Plus, parts like rubber diaphragms are crafted with extreme precision to manage pressure changes and exposure to chemicals.

Choosing Seals and Gaskets as your trustworthy custom molded seal or gasket manufacturer ensures you get products that meet international quality standards, delivering top-notch sealing performance even in the most demanding industrial situations.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Molded Seals and Gaskets In Industry

Our Products

What Are Molded Rubber Gaskets and Seals?

Molded rubber gaskets and seals are specially designed components, crafted with precision, to keep mechanical systems leak-free and protected from contaminants and unwanted vibration. We make these rubber products using various molding techniques like compression, transfer, or injection molding which makes it possible to create complex shapes and hold very tight manufacturing standards.

Unlike standard rubber parts that can be easily trimmed or taken out, our custom-molded rubber gaskets and seals provide better functionality. That's because we can precisely form them to the ideal size and thickness, using high grade materials tailored to your exact requirements.

- Gaskets: These are typically used to bridge the gap between two surfaces that fit together, effectively sealing them off to prevent liquids, gases, or dust from leaking through.

- Seals: Their main role is to stop fluids from leaking or keep out dirt and other contaminants, whether things are moving (dynamic applications) or staying still (static applications).

Advantages of Custom Molded Rubber Gaskets

- Perfect Fit: Our custom molded rubber gaskets are designed to match the exact specifications, ensuring they fit just right every time.

- Durability: Our rubber gaskets stand up better to wear and tear, chemical exposure, and temperature changes, which means they will work effectively over a longer period.

- Material Flexibility: We use various rubber compounds to ensure our gasket or seal is compatible with the specific fluids, gases, or chemicals.

Countries

Industries Served

Projects

Clients

Durable Custom Molded Rubber Seals

We make high-quality, long-lasting custom molded rubber seals designed to perform consistently in challenging environments where ordinary seals fail. Designed with precision, these seals provide excellent protection against pressure, temperature changes, chemicals, and everyday damage. By partnering with a skilled custom seal manufacturer, businesses can obtain sealing solutions specifically designed for their unique equipment and applications.

Whether it's within vehicle motors, aircraft components, healthcare devices, or industrial equipment, these resilient rubber gaskets provide a secure, long-lasting barrier against leaks. Available in diverse rubber materials such as silicone, nitrile, EPDM, and Viton, they are engineered to withstand challenging operational conditions. When applications require a precise fit, exceptional longevity, and reliable operation across diverse industries, custom rubber gaskets are an excellent choice.

Role of Custom Rubber Seal Gasket Manufacturers

As a custom rubber seal gasket manufacturer, we manufacture custom rubber seal gaskets for a wide range of industries. We provide sealing solutions custom-engineered to match specific sizes and withstand challenging conditions. Using our in-depth understanding of materials and modern production techniques, we manufacture premium seals and gaskets that prevent leakage, offer extended durability, and ensure optimal performance. Our expertise lies in:

- Precision Engineering: We really shine when it comes to precise engineering as we make gaskets that match specifications exactly, ensuring a perfect fit and dependable sealing every time.

- Material Expertise: We also possess deep material expertise, offering a broad selection of elastomers like silicone, EPDM, nitrile, and Viton to meet the varied needs of different applications.

- Industry Compliance: We make sure our gaskets adhere to important industry standards like FDA, ISO, and RoHS, ensuring safety and quality.

- Scalable Production: Whether you need some parts or a large production run, we maintain consistent quality throughout the entire manufacturing process.

- Industry Applications: Our custom solutions support a wide range of industries, including automotive, aerospace, oil and gas, food processing, and medical equipment.

Application of a Rubber Diaphragm

A flexible, bendable component commonly known as a rubber diaphragm is typically manufactured using materials such as nitrile, silicone, EPDM, or fluoroelastomers. It provides a tight seal and transmits pressure or movement between different sections of a mechanism. These diaphragms are capable of withstanding changes in pressure and temperature, as well as chemical exposure. It's the adaptability that makes them so crucial across many industries, from aerospace to medical. Diaphragms are mostly used in:

- Pumps and valves to manage the movement of liquids or gases.

- Actuators and regulators to provide precise pressure management.

- Automotive fuel systems help to keep performance accurate.

Effective sealing is incredibly important, and it's hard to overstate how much it matters. Working with a custom molded seal manufacturer or a custom molded gasket manufacturer that focuses on custom-made seals or gaskets ensures you get solutions that are well-engineered and fit your exact requirements. If you need specialized sealing solutions designed just for you, get in touch with us today. We can offer expert advice, custom designs, and reliable help with production.

Ready to See your Idea For Seal & Gasket

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.