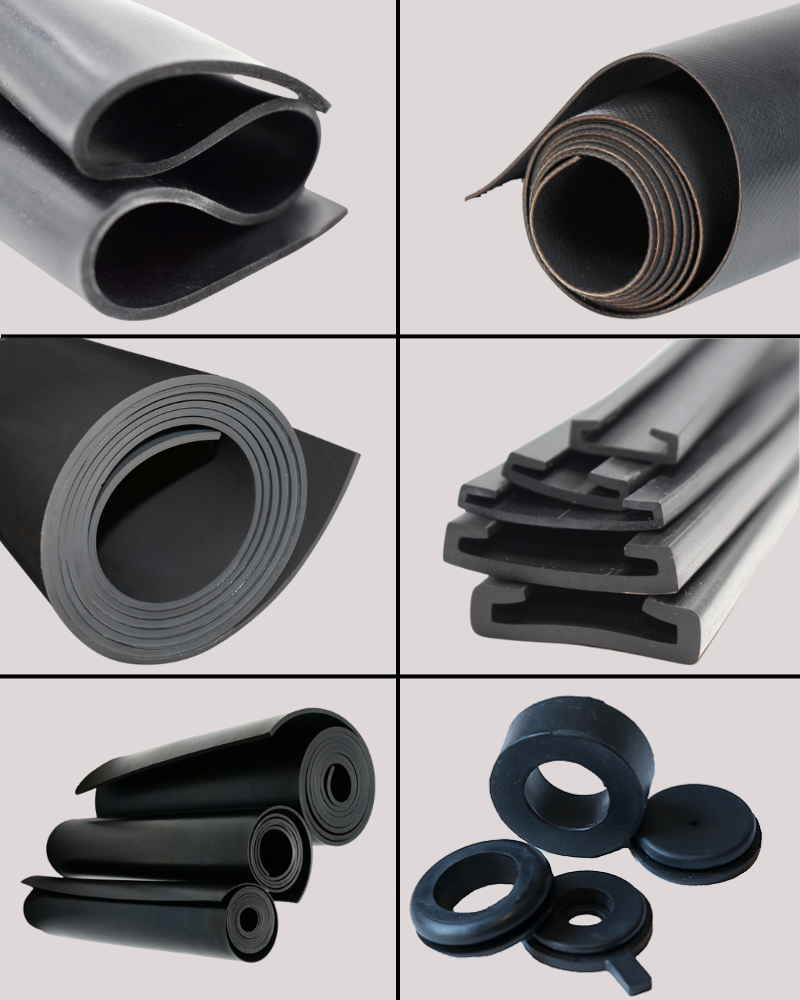

Rubber Seals

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

Rubber Bellows

Sealing Capability

Wide Application

Pressure Resistance

Vibration Isolation

Customizable Design

Rubber Gasket

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

Rubber Grommets

Easy Installation

Noise Reduction

Customizable Design

Vibration Dampening

Weather Resistance

Custom Molded

Seals & Gaskets

Precise Fit

Durable Material

Customizable Shapes

Leak-Proof Sealing

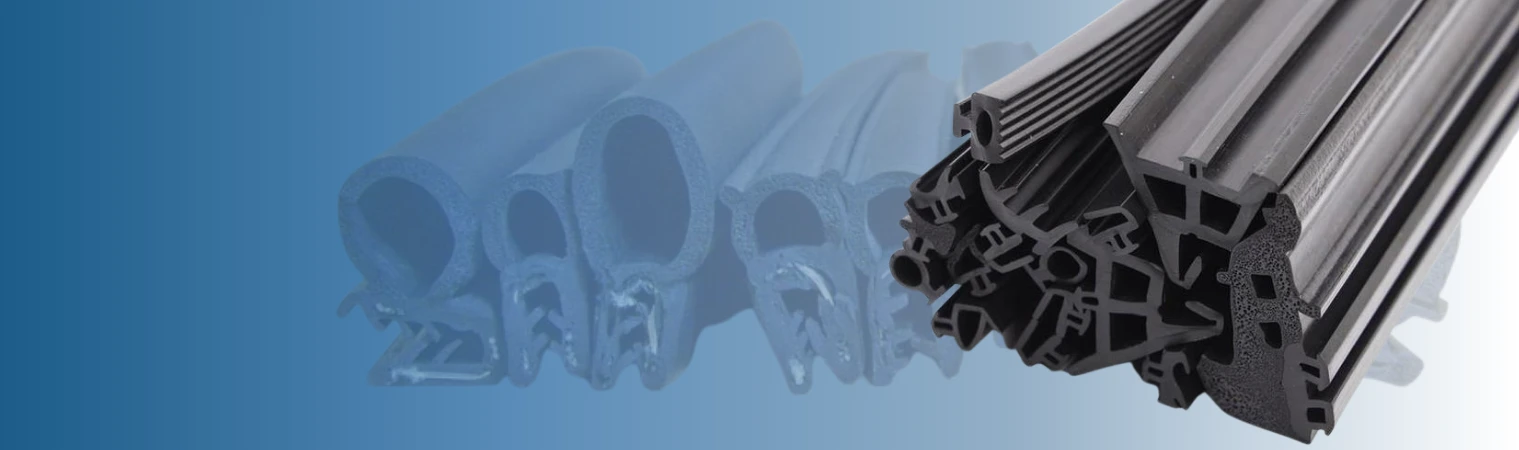

Custom Extruded

Seals & Gaskets

Precision Profiles

Durable Materials

Chemical Resistance

Custom Shape & Size

Rubber Washers

Sealing Capability

Custom Shape & Size

Corrosion Resistance

Durable & Flexible

Vibration Reduction

Rubber Diaphragms

Flexible Design

Leak-Proof Sealing

Custom Shape & Size

Corrosion Resistance

Temperature Tolerance

- Home

- Materials

Top Materials Used for Our Custom Seals and Gaskets

At Seals and Gaskets, we specialize in creating top-notch, custom seals and gaskets tailored to a wide variety of industries across the globe. Selecting the correct material is extremely important for long-lasting performance, efficiency, and safety. We provide a comprehensive selection of advanced rubber materials, each possessing unique properties suitable for different performance requirements. These include heat resistance, chemical compatibility, compliance with FDA standards, flexibility, and mechanical strength. Below is an overview of the primary materials we utilize in the development of custom, precisely engineered seals and gaskets.

Silicone Seals and Gaskets

Silicone is a highly useful material for manufacturing seals. Its popularity stems from its flexibility, resilience, and ability to withstand extreme temperatures, both hot and cold. These beneficial properties make silicone seals and gaskets common in a wide range of applications:

Silicone Heat Resistant

These heat-resistant silicone seals are made to handle high temperatures for extended periods without becoming brittle or losing their flexibility. These are great choices for automotive engines, heating and cooling systems, and various types of industrial equipment.

Silicone High Temperature

Silicone is designed to withstand high heat, remaining stable at temperatures as high as 300��C (572��F). It can withstand high temperatures, making it a good choice for sectors like aerospace, electronics manufacturing, and electricity production.

Medical Grade Silicone

We provide high-quality silicone seals specifically designed for medical uses. Our seals can be used in a range of healthcare applications, from medical equipment and testing tools to surgical instruments. The silicone we use is non-toxic, can be easily sterilized, and is compatible with the human body.

Food Grade Silicone

Silicone gaskets are made from food-grade silicone, guaranteeing they're safe for food. They meet all the necessary regulations for food manufacturing and packaging. Being both odorless and tasteless, and also resisting oils and fats, they're perfect for use in bakeries, beverage production, and dairy industries.

FDA-Approved Silicone

Our silicone seals are completely FDA-approved, ensuring they are a dependable and secure option for various industries. This is particularly important in sectors like food production, pharmaceuticals, and healthcare, where adhering to strict guidelines is essential.

Rubber Seals and Gaskets

We also provide a wide range of rubber materials to meet diverse sealing requirements. Each type of rubber provides unique benefits for specific industries and applications:

- EPDM (Ethylene Propylene Diene Monomer): EPDM rubber is a great choice when you need something that can really withstand weather, ozone, and water damage. Because of its durability, it's commonly used for outdoor seals and automotive parts.

- Neoprene : Neoprene provides a high level of protection against oils, and many moderate chemicals. It's frequently used in refrigeration and heating, ventilation, and air conditioning (HVAC) systems.

- Viton :Viton is a top quality synthetic rubber that's best known for its excellent resistance to harsh chemicals, fuels, and high temperatures. It's frequently used in most demanding industries such as aerospace and the chemical.

- Nitrile (NBR) : Nitrile rubber (NBR) is a great choice when you need resistance to oils and fuels derived from petroleum. It's commonly used in both automotive and various industrial applications.

- Santoprene : Santoprene is a unique plastic that has the flexibility of rubber and the durability of plastic. It is mostly used for weather stripping and automotive parts.

- Natural Rubber : Natural rubber is a popular material choice, well known for its high elasticity, durability, and ability to withstand wear and tear. It's ideal for minimizing vibrations and absorbing shocks.

Other Materials We Use

Thermoplastic elastomers (TPEs) combine the qualities of both plastics and rubber. They are versatile, recyclable, and widely used across industries. Seals and gaskets made from TPE provide flexibility, effective environmental protection, and are common in automotive and electronic casings.

PTFE, also known as Teflon, is highly chemical-resistant and heat-tolerant. It offers low friction, non-adhesive properties, and effective sealing. Industries such as chemical manufacturing, food processing, and medical rely on PTFE for its durability, low leakage, and safety.

Custom Solutions for Every Industry

At Seals and Gaskets, we will help you find the perfect material. We use top quality materials, such as various types of silicone and rubber. Whether you need FDA-approved silicone seals for the food industry, PTFE seals for chemicals, or heat-resistant silicone for industrial machinery, we provide accurate solutions to meet your requirements. Reach out to us today and we'll provide expert guidance to help you choose the best sealing material for your specific application.

Ready to See your Idea For Seal & Gasket

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.