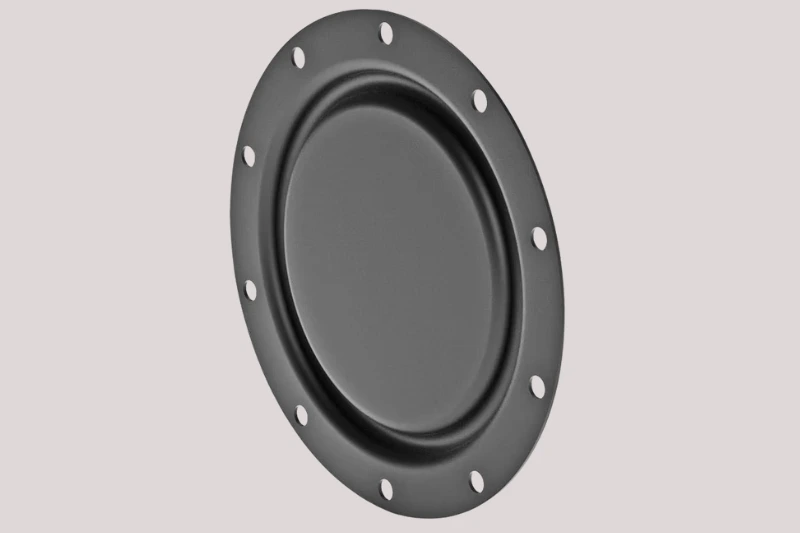

Rubber Diaphragms

Flexible Design

Leak-Proof Sealing

Custom Shape & Size

Corrosion Resistance

Temperature Tolerance

- Home

- Rubber Diaphragms

Custom Rubber Diaphragm Sealing Solutions

Rubber diaphragms are essential sealing parts used across many industries to maintain separation between liquids, gases, or different pressure levels. Diaphragms are flexible and protective barriers that effectively prevent leakage while still allowing pressure or mechanical force to pass through.

At Seals and Gaskets, we focus on making high-quality diaphragms that cater to the diverse requirements of various industries, including automotive, pharmaceutical, aerospace, medical, and industrial sectors. So, if you need a durable rubber diaphragm seal for things like pumps, valves, regulators, actuators, or sensors, you can rely on our careful design process to deliver consistent, long-lasting performance and effective sealing every time.

As an experienced rubber diaphragm manufacturer, we provide both standard and custom options, all designed to meet your exact size, material, and performance needs. We use cutting-edge molding techniques and top-grade rubber materials like silicone, Viton, Neoprene, Nitrile (NBR), and EPDM. This ensures our diaphragms are strong enough to handle high-pressure and extreme temperature conditions.

We are dedicated to delivering you products that perform exactly as needed, are affordable, and arrive on time. With our understanding of precision-molded diaphragms and the ability to handle both small batches and large-scale production, we're the reliable partner you can count on for all your diaphragm needs.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rubber Diaphragms In Industry

Our Products

Why Choose a Rubber Diaphragm Seal?

Rubber diaphragm seals are a popular choice in many applications due to their adaptability and reliable operation. Some of the main reasons they're so useful are:

- Leak-proof sealing: Prevents liquids and gases from leaking into pumps and valves.

- Flexibility: Can withstand ongoing pressure without losing its shape or effectiveness.

- Chemical and temperature resistance: Best for industrial environments with strong chemicals and extreme temperatures.

- Customization: Can be designed specifically for your unique application.

Expertise in Molded Diaphragm Production

We use cutting-edge molded diaphragm production methods to ensure top-notch quality and accurate results every time. Making each diaphragm involves using modern machinery and strict attention to detail, all to meet the exact design specifications. We combine our experience with advanced technology to manufacture exceptional molded diaphragms that perfectly meet or exceed all our customers' requirements.

We use several molding techniques, like compression, transfer, and injection molding. These processes are essential for achieving consistent thickness, precise dimensions, and superior durability in our products. Our molded diaphragms are commonly found in valves, pumps, actuators, and fluid management systems, where they provide flexibility and excel at handling pressure, heat, and harsh chemicals.

Countries

Industries Served

Projects

Clients

Our Effective Diaphragm Solutions

We offer a diverse selection of precision-molded diaphragms, perfect for use across many different industries. Our team is dedicated to focusing on several key areas to make sure we provide top-quality diaphragms for you.

- Material Selection: We use a wide range of elastomers, such as silicone, EPDM, Viton, and natural rubber.

- Design Expertise: We collaborate closely with our customers to develop customized diaphragm solutions tailored to their unique requirements.

- Advanced Manufacturing: We use advanced molding processes to guarantee consistent, accurate, and efficient manufacturing.

- Quality Assurance: Every single diaphragm we make goes through comprehensive testing to ensure it meets both industry standards and your specific needs.

If you're looking for custom rubber diaphragms or silicone rubber diaphragms, you've come to the right place. We offer high-quality, dependable solutions crafted specifically for your needs. Our main focus is on creating durable and adaptable diaphragms that perform outstandingly across a wide range of uses, including automotive, medical, and industrial equipment. Feel free to reach out to our team whenever you need to discuss your diaphragm requirements. We're ready to offer expert guidance on selecting the right materials, exploring design options, and finding the perfect solution tailored to your application.

Ready to See your Idea For Seal & Gasket

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.