Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

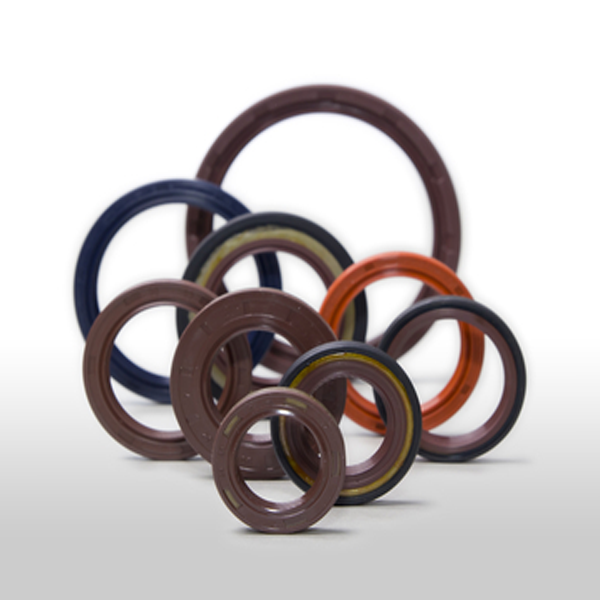

The aerospace rubber mold parts are some of the vital elements that determine the safety, durability and the perfect functioning in high-pressure flight condition. These components are designed to survive under severe temperatures, vibration, changes in altitude and chemicals. Aerospace rubber mold parts come in forms of seals and gaskets, vibration dampers and insulation components; these components are produced using highly developed materials and are made to fulfil the high standards of the aviation industry. To ensure reliability the manufacturers apply high-precision tools, aerospace grade elastomers and test procedures.

All the molded items need to be structurally sound in the extreme working environment. Aerospace rubber mold products are custom-built components in aircraft engines, landing gear systems, cabin interiors, electrical assemblies, and fuel systems to facilitate easy and safe flight operation. These are critical parts of the modern aviation technology and the long-term performance of the aircrafts, with innovation, accuracy, and high level of engineering.

Call Us At

Silicone molds intended to be used in the defense industry are produced to achieve durability, precision and the need to perform on a mission critical basis. The components made with these molds are to carry military vehicles, surveillance, communication equipment, protective gear and advanced weapon technologies. Silicone molds in the defense industry should not be subjected to any extreme heat, pressure, impact or violent environmental factors thus silicone is the best material to use due to its strength and flexibility. The manufactures design custom molds to meet specific defense requirements, which make the components to achieve strict military requirements.

Defense Industry Silicone Molds are used in the defense industry either to seal systems, enclosures, digital protection, or to design purpose-built components, which are high in stress levels and therefore demand long-term reliability. They are needed in the defense sector where the performance and precision cannot be compromised and they can support rapid prototyping, precision shaping and consistent production.

The custom molds aerospace components are designed to manufacture aerospace parts that are highly specialized and match the demanding nature of flight and space missions. With the help of these molds, manufacturers are able to produce accurate parts like engine seals, airframe parts, insulation parts, aerodynamic parts and housings of electrical systems. Custom mold aerospace parts enable designers to attain the perfect geometries, lightweight frameworks, and high-quality performance materials needed in the current aircraft. The production of the molds is done by CNC machining, CAD modeling, and temperature resistant materials to provide perfect production. These molds are tightly tested and validated due to the nature of aerospace industry that must be in full compliance with the global aviation standards.

Aerospace components Custom molds allow innovation the complex designs made possible by custom molds, the shorter production cycle, and the uniform quality of the product make custom molds invaluable to both commercial and military aircraft production.

Military grade rubber molding is designed to be able to cope with the most demanding performance requirements in the defense operations. The applications of these molded parts include armored vehicles, communication systems, weapons, marine vessels, aircrafts and survival equipment. Military grade rubber molding involves the use of special elastomers which are resistant to extreme temperatures, chemicals, shock, and wear components of the environment. The finished products are seals, gaskets, vibration isolator, protective boots, missile system parts, and seals of battlefield ready equipment. Such manufacturers are under stringent military specification and are subjected to strict testing to ascertain that every component is working to its combat level. Military grade rubber molding improves the reliability of the equipment, safeguards the vital facilities, and contributes to the success of the operations. The high quality and reliability of its product make it critical in mission-critical situations where failure cannot be tolerated.

Custom rubber silicone molds play a vital role in delivering high precision, durable and correctly sized components in all industries. When you choose us for your custom mold needs, you are choosing a trustworthy partner committed to precision and quality.

Aviation parts silicone mold manufacturer is crucial in the manufacture of aircraft and aerospace systems, high precision components. These manufacturers come up with silicone molds that can be used to shape complex parts of the aviation, including seals, ducts, connectors, insulators, and cabin system parts. With the company being a manufacturer of silicone molding of aviation parts, it emphasizes on precision engineering, heat resistance, flame resistance and longevity. The silicone molds enable the production process to be flexible, accurate and repeatable which ensures that the quality of the parts produced remains the same. Aviation applications are so strict that they require that the world safety and performance requirements be met to the letter and therefore every mold is tested thoroughly. Precise tooling, high-quality silicone in aerospace-grade and high-tech methods of molding are employed by manufactures to get perfect results. The competence of a supplier of silicone molds of aviation parts contributes to the reliability of aircraft components, their lightweight and durability, facilitating the flight activities to be safe and efficient.