Injection Moulding

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

It has been a long time since you are looking for injection moulding companies now. However, you are not quite sure of the firm whom you can trust, especially when you get the chance to come across so many of them. Looking for any one among the lot might seem to be an easy task but once you get hold of it, you will realize that it is not that simple. You will be bombarded with their fluent talks as every injection molding company claim to be the best in this field. Going for the basic one seems to be a bit different but when you have us by your side, your search now comes to an end and for good reasons.

Even though the competition is pretty tough, there are some reasons to choose our injection moulding company as the best one so far. There are various reasons behind that.

If you are planning to join the best injection mould company in town, then we would like to welcome you to come and give us a try. Once you have chosen us, there is no need to look any further.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Injection Molding In Industry

It is true that you will be aiming for the best ever injection mold company in town. Well, you will be spending money for their services. That’s why our package seems to be making the cut for you.

It is really important to know more about the best injection molding company and that’s when our name seems to be popping right on your screen. We offer the best molding help as you have asked for it.

Are you on the lookout for the best plastic components manufacturers in the industry? The search can be overwhelming with numerous options claiming to be the top players. However, your quest ends here, and for good reasons, as we stand out among the leading plastic manufacturers.

Choosing the right plastic moulded components manufacturer is crucial, and we invite you to experience the difference with us. Once you partner with us, there's no need to explore further.

Your search for the best plastic mold company ends here. We provide unparalleled molding services that align with your expectations.

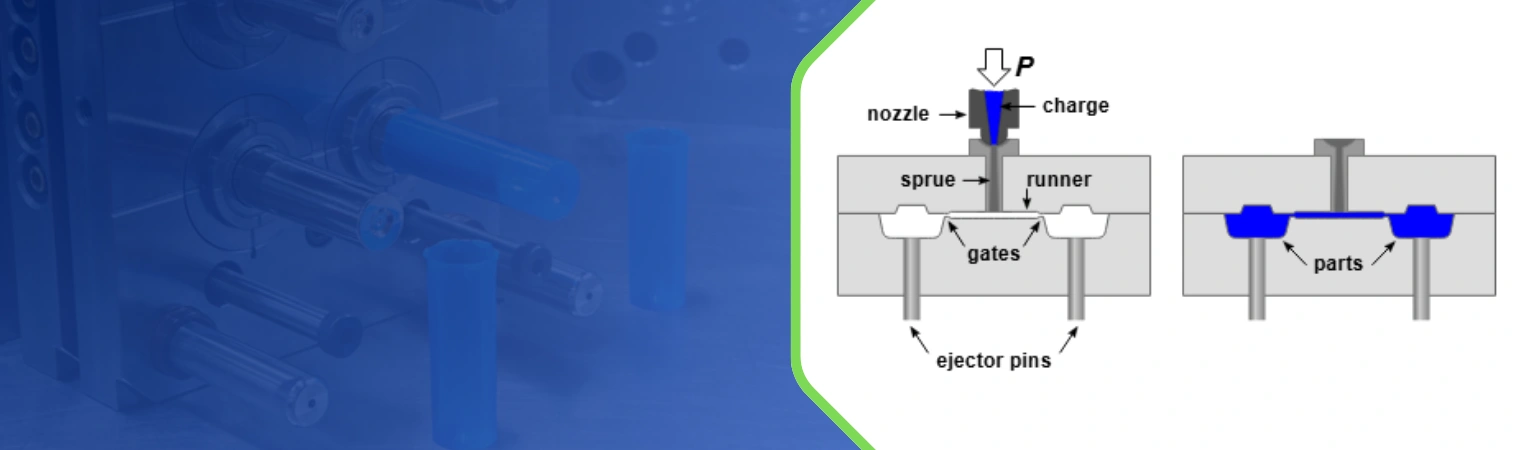

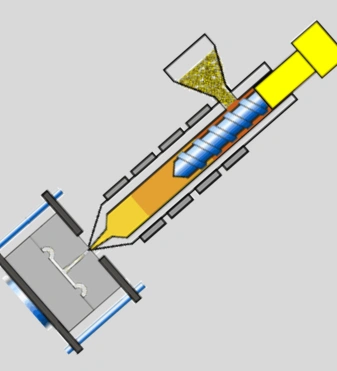

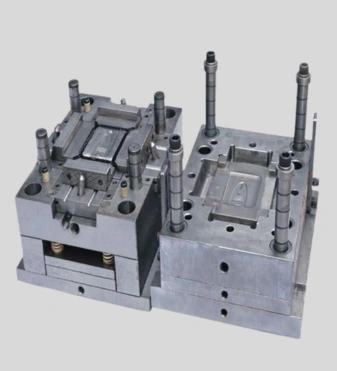

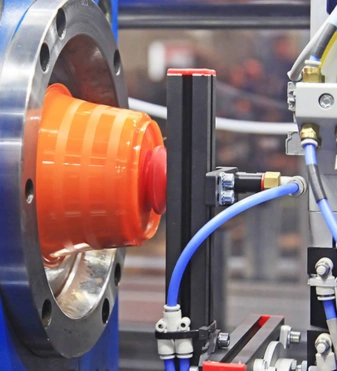

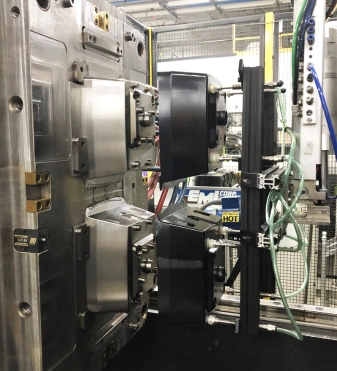

An injection mould company specializes in the design and production of parts necessary for the injection moulding process. Injection moulding is a method of manufacturing that is typically used to create various plastic components with efficiency and accuracy. These companies play a vital role in the early stages of production, creating the moulds that determine the shape and form of the final plastic product. The services offered by moulding companies cover various stages of the manufacturing process. This includes precise mould design, prototyping to test and refine the mould, and actual production of the mould from a durable material such as steel or aluminium. The resulting moulds are used to produce large quantities of plastic parts in injection moulding machines that various industries use, ensuring the creation of precision plastic parts that are integral to everyday products.

Cost-Effectiveness: An injection mold company specializes in mass production, providing cost-effective solutions for industries requiring significant quantities of plastic parts or components.

Precision and consistency: These molding companies ensure consistent quality and accuracy in each produced item, which is important for industries like automotive and electronics that demand precision.

Versatility in material selection: They provide expertise in material selection that guides customers to choose materials that appropriately align with specific flexibility and durability requirements.

Expertise in Injection Molding: They have technical knowledge in injection molding processes that guarantee optimal results with a focus on meeting industry standards.

Customization Options: These companies also offer customization options, tailoring molds to meet unique project needs and requirements.

Intricate Design Replica: They consistently excel in replicating complex designs, making them suitable for projects requiring detailed plastic parts.

Countries

Industries Served

Projects

Clients

When seeking excellence in plastic mold companies, our name emerges at the forefront. We are dedicated to delivering unmatched molding assistance, making us your ideal choice.

Choose us as your preferred plastic components manufacturer, and you won't regret the decision. We're here to guide you seamlessly through the process, providing unmatched expertise and support. Whether you're in search of plastic molded components or reliable mold companies, we've got you covered!

Next time you are looking for mold injection companies near me, try to give us a shot. We are pretty sure that you won’t regret taking this decision at all. We are here to help and guide you through the process with ease. So, next time you are looking for injection mold components suppliers, be sure to get to us now for the same!

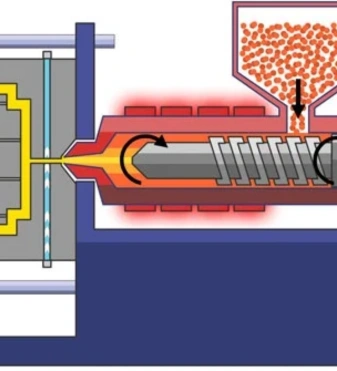

The requirement to optimise our manufacturing cycles is unavoidable as our industries develop. From raw materials to tooling, we strive for cost effectiveness and excellence. In the plastics business, we may witness advances in machinery and tooling. Plastic manufacture has advanced dramatically over the years. Consider plastic injection moulding. The art dates from the nineteenth century.

Since then, the polycarbonate injection moulding has evolved to the point of incorporating automation into the cycle. Polycarbonates are being used as raw materials in injection moulding. Polycarbonate injection moulding is gaining popularity because to the numerous advantages it offers.

This method produces parts with a wide variety of geometric complexity. You'll also have excellent part-part reproducibility. This means that the technique is well-suited for long-run manufacture of comparable parts. This entails producing high-precision components that do not require polishing or grinding. It's sometimes referred to as ultra-precision thermal pressing. It has grown in prominence as a result of the increased demand for advanced light handling components.

With over ten years of expertise, Plastic Injection molds principal business and working as injection molding manufacturer. Household moulds, kitchenware injection moulds, home appliance mould tools, industrial and agricultural injection moulds, and so forth.

Heya Mold's mission is to quickly execute personalised customization and one-stop mould solutions to fulfil customer demands using our skill and knowledge. To that aim, Heya Mould emphasises on producing high-quality and standard plastic moulds, providing clients with more appropriate and sturdy plastic mould structures that are easier to run and maintain.

We have a strong technical staff that creates 2D and 3D product designs and mould designs based on client specifications utilising CAD/CAM/CAE technology. The firm has modern mould-making machinery such as a high-speed CNC machine, a 5-axis CNC machine, a 3+2 CNC machine, EDM, a sodick wire-cutting machine, a gun drilling machine, a grinding machine, and so on.

Polypropylene (PP) is a strong and rigid thermoplastic polymer that is widely utilised in industrial applications. A semi-crystalline structure produces excellent flexural strength and resilience to a wide range of chemicals and acids, allowing it to be used in a wide range of goods. Polypropylene plastic is a common material option for applications ranging from automobile components and medical devices to packing trays and consumer items because to its light weight and low cost.

Polypropylene is used by Plastic Injection Molds for injection moulding projects of various sizes and volumes. We are committed to offering high-quality workmanship and polypropylene molding at a reasonable price. We can manage your project from start to finish since we have in-house design and engineering capabilities as well as secondary machining services.

We have the competence to handle difficult and close tolerance needs, as well as to create components in a variety of part geometries. Our staff works hard to understand your requirements and goes above and beyond to provide outstanding bespoke injection moulded components.