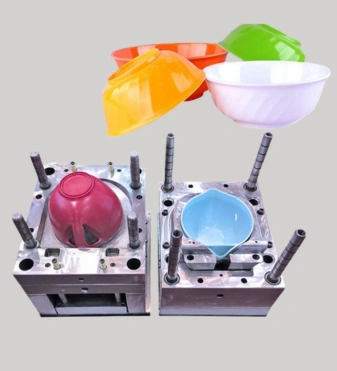

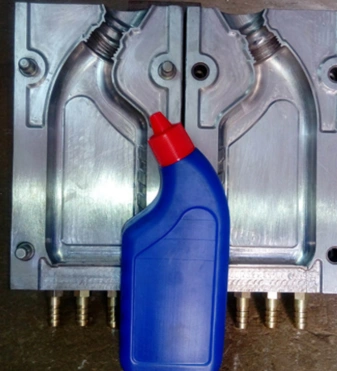

Plastic Dies

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

The plastic die mold is mainly working out as a one-time investment plan. Once you have purchased the mold, it is subject to last the longest. It is really important to know more about the best plastic molds and die mould manufacturer you can get help from.

Right now, technology has come a long way since crude tools were invented. Everything needs to be done by hand and one by one back then. But, now, you get the opportunity to make thousands of items in one single shift. That’s an interesting idea to ponder and you will need molds and dies for the same. Among all the chosen manufacturing processes available, you can easily state that plastic molding and the die casting are some of the most popular and widely used processed in the current belt buckle manufacturing and in some other firms. Therefore, it is important to know more about the makers first before taking the next step.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Moulding Die In Industry

If you are looking for particular dies which can help give plastic a perfect shape and size, then you better watch out for the best plastic die maker to help you with the same. Well, once you have chosen us, there is no looking back.

As we have been into this field for a pretty long time, you can expect only the best help from our plastic injection moulding die makers for sure. So, no matter how customize your ideas are, you can get it straight from our side.

So, join us as your injection moulding die maker and avoid wasting any time extra. You will be amazed with the available options we have in store for you.

Countries

Industries Served

Projects

Clients

Professional injection moulders are needed since plastic injection moulding is a commonly utilised production procedure. This article will give you advice on how to locate affordable options if you're looking for local plastic injection moulders. We will also go over the expenses of plastic injection moulding as well as the availability of plastic injection molding machine for sale.

Take into account the following actions when looking for plastic injection molders near me:

Research and Referrals: Look up information online and ask for referrals from coworkers, trade groups, or regional producers. This can enable you to choose trustworthy injection moulders who are well-known for their knowledge, superior products, and dependable services. Assess Experience and Expertise: Look for injection moulders who have a lot of experience with the products you need or in your sector. Examine their knowledge of handling different materials, the complexity of the parts, and their commitment to quality standards. Request comparisons and quotes: Contact a number of injection moulders and ask for quotations on your job. Compare the costs, services provided, lead times, and techniques used for quality control. For accurate quotations, be sure to include thorough specs and any unique requirements.

The price of plastic injection moulding is influenced by a number of factors. Here are some crucial things to remember:

Part design and complexity: Complicated part designs, intricate features, and close tolerances often call for more sophisticated moulds and manufacturing techniques, which raises the cost of production. Material selection: The price of various plastics varies. The cost of materials can be affected by variables such material availability, specifications for performance, and regulatory compliance.

Mould Design and Tooling: plastic injection molding cost depends on the size, quantity, and complexity of the cavities in the mould. Additionally, a sizeable portion of the final cost may be attributable to tooling expenses for making the moulds. Production Volume: The number of parts produced has an impact on the final price. Because of economies of scale, higher production volumes typically result in cheaper per-unit costs.

You must conduct extensive research, evaluate potential candidates, and get numerous quotations to find affordable plastic injection moulders close to you. You may make more informed choices if you are aware of the aspects of plastic injection moulding costs, such as component complexity and material selection. Look into possibilities from reliable manufacturers, licenced distributors, or dependable dealers in the used machinery market or on online marketplaces if you're thinking about buying an injection moulding machine.

If you've been on the quest for a reliable plastic die mould manufacturer, your search concludes with us. Navigating through the myriad options can be a daunting task, but with our expertise, you'll find the assurance you seek.

Selecting the right moulds and dies manufacturer is pivotal, and we invite you to experience excellence with us. Opting for our services eliminates the need for further searches, ensuring satisfaction with every project.

Investing in moulds and die manufacturers is a significant decision, and we recognize the importance of your investment. With us, you can trust that your choice aligns with your expectations.

Understanding the nuances of selecting the best plastic die mould manufacturers is crucial, and we take pride in being your top choice. Experience unparalleled service and customer-centric solutions when you collaborate with us.

When searching for moulds and dies manufacturers, consider giving us the opportunity. Your decision to partner with us will undoubtedly be a step towards seamless and reliable plastic die mould manufacturing. Connect with us today for all your mould and die needs!