Epdm Extrusion

Weatherproof

UV Resistant

Long Durability

Premium Quality

High Performance

SLS 3D Printing

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Custom 3D Printing

Heat Resistant

Long Durability

Protective Sealing

High Compression

Customizable sizes

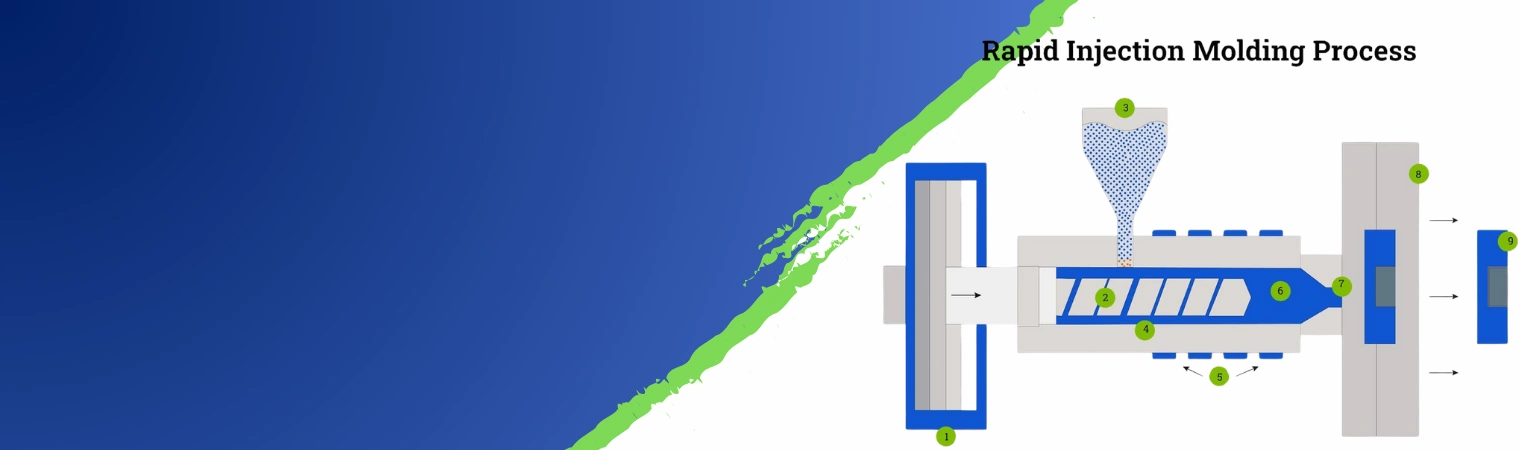

Rapid Injection Moulding

High Elasticity

Reliable Sealing

Custom Sizes

Weather Resistant

Superior Performance

Mold Manufacturer

Perfect Fit

Anti-Vibration

UV Resistant

High Precision

Easy Installation

Custom Mold

High Durability

Smooth Finish

Superior Quality

Custom Shapes

Versatile Use

Plastic Molded Products

Smooth Flow

High resilience

Custom Lengths

Leak Prevention

Chemical resistant

- Home

- Materials

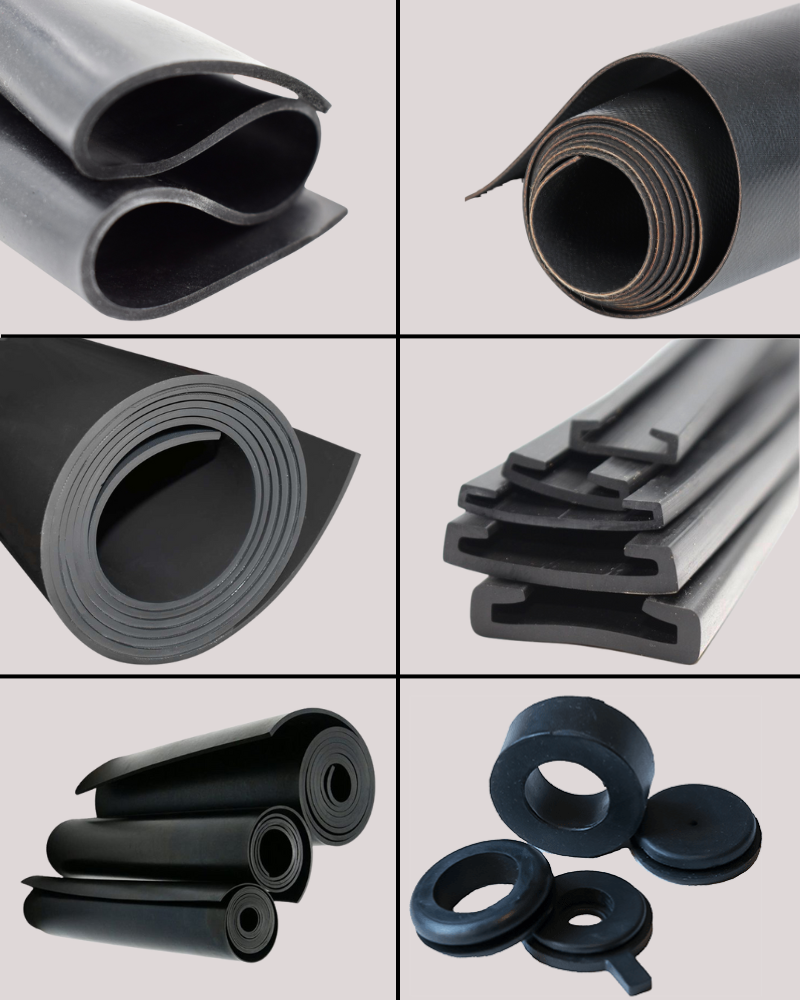

Materials We Use for Custom Rubber Extrusion

At Custom Rubber Extrusion, we're experts in manufacturing top-notch rubber profiles, seals, and gaskets using high-quality materials that ensure long-lasting performance. The key to any successful extrusion project is choosing the correct rubber material, since every type has its own specific mechanical, thermal, and chemical characteristics.

We use a variety of high-quality rubber compounds, such as EPDM, Silicone, Neoprene, Nitrile (NBR), and Natural Rubber, to make sure we can deliver the right solution for your needs. Our wide range of materials perfectly suits the specific application and the needs of the industry. Let's take a closer look at each material to see its specific properties, benefits, and ideal uses.

Types of Materials

HDPE Molding

High-Density Polyethylene offers strong chemical resistance, impact strength, and durability, making it ideal for containers, industrial parts, and piping components.

Polypropylene (PP)

PP is lightweight, flexible, and resistant to fatigue. Commonly used in automotive parts, packaging, hinges, and living hinges.

Acrylonitrile Butadiene Styrene (ABS)

ABS combines strength and toughness, making it perfect for enclosures, toys, appliance housings, and automotive trim.

Polystyrene (PS)

PS is lightweight and cost-effective, commonly used in consumer goods, packaging inserts, and laboratory ware.

Polyoxymethylene (POM)

Also known as acetal, POM is excellent for precision parts, gears, bearings, and components requiring high stiffness.

Polyethylene (PE)

PE is tough and flexible, making it suitable for bottles, films, liners, and general-purpose molded products.

Nylon (PA)

Nylon offers excellent strength, abrasion resistance, and thermal stability—widely used for mechanical components and gears.

Polymethyl Methacrylate (PMMA)

Also known as acrylic, PMMA is used where clarity and optical transparency are required—light covers, lenses, and displays.

Low-Density Polyethylene (LDPE)

LDPE is soft, flexible, and lightweight—commonly used in bags, tubing, and squeeze bottles.

Polycarbonate (PC)

An extremely tough thermoplastic used for impact-resistant parts, safety products, machine guards, and optical components.

Thermoplastic Elastomer (TPE)

TPE combines the flexibility of rubber with easy processing. Used for grips, soft-touch products, and seals.

Thermoplastic Rubber (TPR)

Known for elasticity and durability, TPR is widely used in footwear, soft-touch components, gaskets, and flexible parts.

Comparison Overview for Choosing the Right Material

| Material | Temperature Resistance (°C) | Oil Resistance | Weather Resistance | Applications |

|---|---|---|---|---|

| EPDM | -50 to +130 | Poor | Excellent | Outdoor seal, automotive weatherstrips |

| Silicone | -60 to +230 | Fair | Excellent | Food, medical, aerospace |

| Neoprene | -40 to +120 | Moderate | Good | HVAC, marine, industrial seals |

| Nitrile | -30 to +120 | Excellent | Fair | Oil, seals, automotive hoses |

| Natural Rubber | -40 to +80 | Poor | Fair | Shock absorption, vibration pads |

Why Choose Our Custom Rubber Extrusion?

At Custom Rubber Extrusion, we're really proud to make high-quality rubber extrusions that are precisely made to fit your specific needs. We use our deep knowledge, modern equipment, and material expertise to guarantee that every single profile performs well, lasts a long time, and is consistently reliable. The key reasons to choose our customised rubber extrusion products are:

- Top-Notch Materials:We only use the best rubber materials like EPDM, silicone, neoprene, nitrile, and natural rubber to make sure your project gets the best possible outcome.

- Custom Design:We can customise extrusion to your exact needs, including the shape, size, firmness, and material to ensure it fits and works perfectly.

- Advanced Manufacturing Equipment: Our cutting-edge equipment and tools ensure that every profile is precise, consistent, and has an excellent surface finish.

- Strict Quality Control: Every single product we make is thoroughly checked and tested to meet high-quality standards

- Long-Lasting Performance: Our extrusion profiles withstand extreme temperatures, harsh weather conditions, and chemical exposure, ensuring dependable performance for a long time.

Custom Solutions for Every Industry

Choosing the appropriate material is extremely crucial to ensure the durability and performance of rubber extrusion profiles. The materials like EPDM, Silicone, Neoprene, Nitrile (NBR), and Natural Rubber all have distinct characteristics that make them good for particular applications. We focus on accuracy, quality, and consistency in all our extrusions, helping your projects be successful in a variety of sectors. We carefully check, confirm, and process every material we use to fit your exact needs. This guarantees excellent results in various industries, including automotive, construction, medical, and aerospace, etc.

Ready to See your Idea For Plastic Injection Molds

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.