Injection Plastics Molding

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

This might be the very first time when you are hearing of the term precision plastics injection molding and have no clue what it actually means. It is a procedure where you get the chance to melt the plastic pellets, through thermosetting or thermoplastic polymers, which was once malleable enough and will get injected at pressure into mold cavity. It will then fills and solidify for producing the final item. We are ready to offer you with the top-notch services, waiting for you to address. We are ready to cover the needs much like you have asked for it!

The injection molding plastics are here to address your needs and we will help you with the procedures to follow for the same. The thermoplastic injection molding procedure is the standard example with aluminum mold.

It is true that you are focusing on the quality when it comes to plastic injection molding. So, you want the best deals over here for help. Well, once you have chosen us for the injection molding, no need to look any further.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

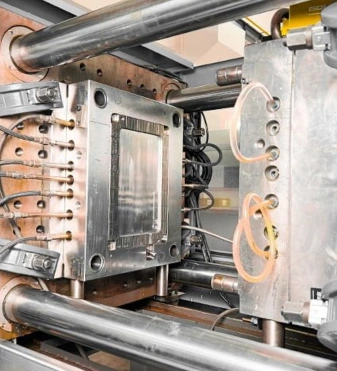

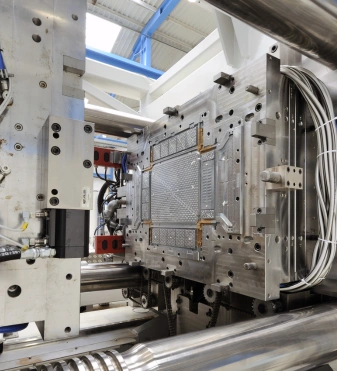

Plastic Injection Molding In Industry

When the run is complete of the plastic mold injection procedure, the parts or the initial sample run will then get boxed and then shipped shortly after. If you want, you can request for your design cube for free, which will show the surface finishes, along with the thin and thick finishes.

So, what are you waiting for? In case you are dealing with the cheap plastic injection molding, be sure to get to us for the same.

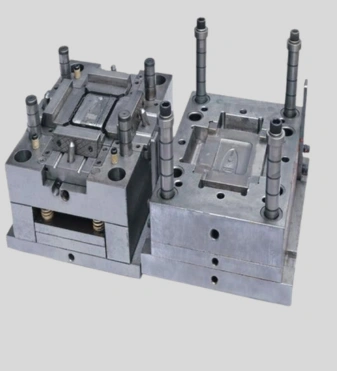

Plastic die moulds are essential in the industrial industry for creating precise components. These dies, often referred to as moulds, are painstakingly manufactured to mould molten plastic into exquisite shapes. This blog will examine the world of producing plastic die moulds, the importance of die and mould makers, and the use of precise parts in numerous sectors.

Countries

Industries Served

Projects

Clients

plastic die mould manufacturer is essential to the manufacturing process because they provide high-quality moulds that allow the production of precise components. They are necessary for the following main justifications:

Manufacturers of moulds and dies use a number of procedures to produce precise, high-quality moulds. An outline of their skill is provided below:

Manufacturers of plastic molded precision components essential to the industrial sector because they create precise moulds that transform molten plastic into precise and detailed parts. Their knowledge, experience, and attention to detail guarantee the manufacturing of fine precision parts that are used in a variety of sectors.