Rapid Injection Moulding

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

The process of managing the liquified plastic into different shapes and forms is itself the best instance of combining art and science. Technology forms the pillar of these methodologies as it wouldn't have been possible without the injection moulding services.

If you are planning to improve the accuracy level of manufacturing without affecting the rate of production, the only way to achieve so is by applying the injection molding technique. Maintaining perfection at the minute level is possible only when you manufacture the larger products in sections and then assemble them to form the perfect version.

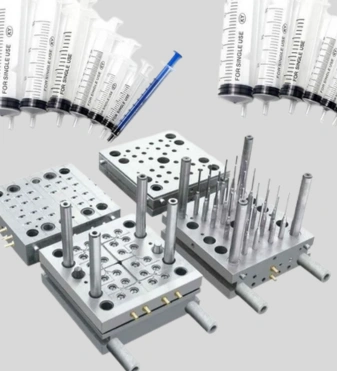

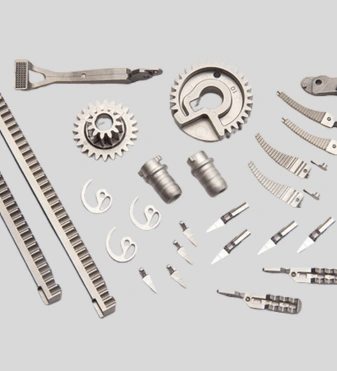

The service providers for injection moulding near me are all into manufacturing objects related to the automotive or healthcare industries. In both cases, you will need to create huge volumes of different minute parts. Only the injection molding technique can help you to attain accuracy at 100th of one millimeter. The product can be as simple as a hair comb or something as complicated as a component for a smartphone or rocket ship.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Advanced Molding Process In Industry

The injection moulding price is comparatively low because you don't have to recruit many human resources for operating the system

It is evident that the necessity of human labor is almost nil in the entire process if you want to go for complete automation.

You can achieve even the most intricate designs flawlessly at the injection molding factory as it is not a manual process but a digital one that can never make a mistake. Technical problems may come up at times. But that won't harm the quality of the product. The excellent software will allow to evaluate the 3D prototype accurately before starting commercial production.

Countries

Industries Served

Projects

Clients

The injection moulding manufacturers do not have to worry about the ratio of combining metals or liquids. For accuracy, the molding systems use automatic measurement systems to avoid any controversy or mistake in the quantities of the components. Hence, it is possible to achieve excellence without much effort.

With the integration of 3D printing, the injection moulding suppliers are now glad to present the latest systems that will help you to create the prototypes faster than imagination. It will provide you with the opportunity to analyze the product thoroughly and change the features if you feel. You get the power to make changes before making the final product.

rubber injection molding is a successful modification of the plastics production method because it heats the rubber and uses significantly more pressure per square inch of cavity surface. In contrast to the plastic injection molding procedure, which cools the materials under less pressure, this is different. Through several developments, injection molding has frequently emerged as one of the most effective methods for producing molded rubber goods by best injection moulding manufacturers.

Effective material preparation serves as the foundation for injection and injection-transfer molding. Molded rubber is used in several industries all over the world. Some of the must-have applications essential for many firms include rubber vibration isolation, rubber injection molding, extruded rubber, and rubber-to-metal bonding. These little items are crucial for machines and vehicles, determining whether routine activities succeed or fail.

Injection molding is now the most widely used method because of its ease of usage and wide range of applications. When molding rubber by injection, uncured material is distributed into a mold using a nozzle, carefully positioned sprues, and runners. The rubber cures after flowing into hold cavities. The history of injection molding begins with polymers. Even when best injection moulding manufacturers develop distinctive machinery with specialized functions, the challenge of producing such innovations with the best possible efficiency and lowest possible cost arises. The answer is often unique to each situation.

Custom rubber injection moulding can help with it. One firm that can offer bespoke rubber components, rubber molding, silicone rubber products, and more is ours. There are countless options. Our ability to make use of the most up-to-date methods and effective procedures for rubber molding, extrusion, and bonding allows plastic injection molds to assist in the conception and completion of products that will completely satisfy your requirements.

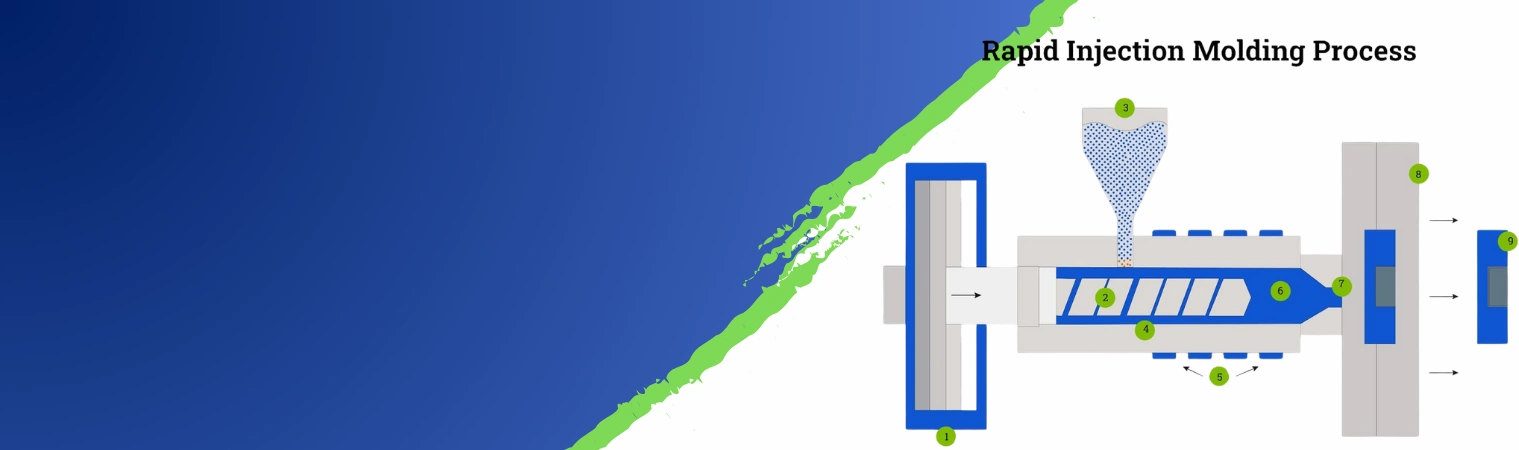

Many best injection moulding manufacturers and enterprises have certain requirements for components. A key component of many processes is rubber molding. These are not cheap tricks or make-do solutions. If you're having trouble locating answers or sources, we can be of assistance. The more well-known plastic injection molding method and rubber injection molding are extremely similar. The process begins with the entry of the raw rubber strips into the machine through a hopper.

After passing through the hopper, it moves into the screw chamber, where external heaters and friction from the screw's movement heat and compress the material. The rubber has heated to an extremely fluid condition around the screw's end. High pressure is used to feed it into the mold, filling the void made within the rubber mold. Rubber fills every crevice of the cavity because of its flow characteristics.