- Home

- Injection Molding Defects Fixes

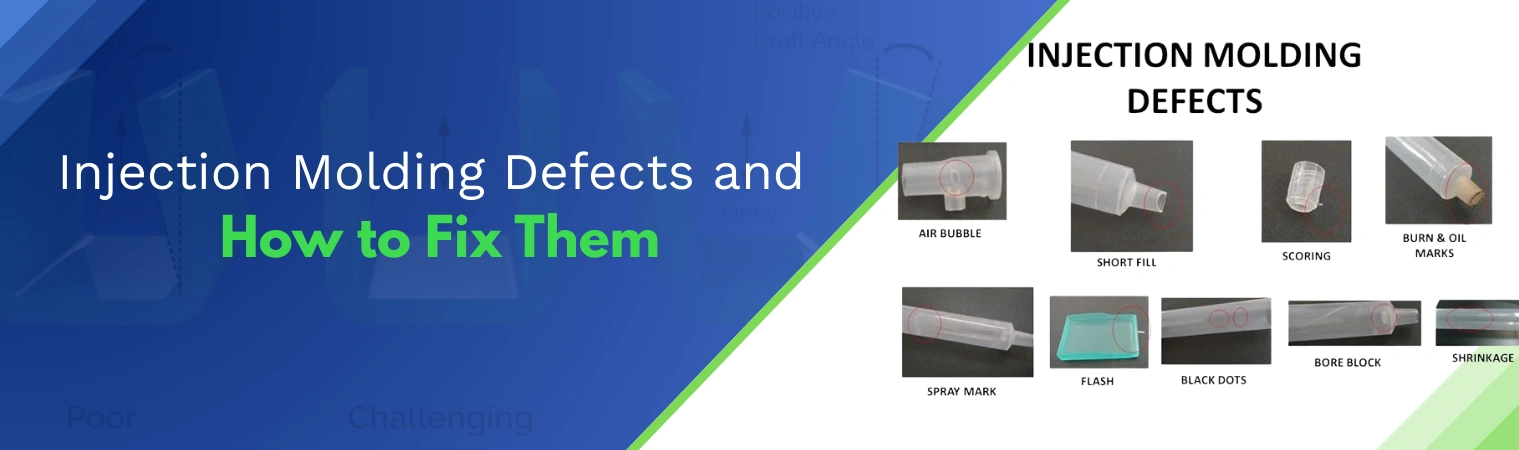

Injection Molding Defects and How to Fix Them (Complete Troubleshooting Guide)

In modern manufacturing, consistent part quality remains non-negotiable. We, the manufacturers, know fully well how small defects occurring in injection molding can hamper production rates, increase rejection rates, and, above all, shake customer confidence. This is why we resort to a very straightforward logical approach to troubleshoot and correct problems in order to control costs. This complete troubleshooting guide describes practical insights obtained from real challenges faced daily in our company.

Why Injection Molding Defects Occur

Every defect has a root cause—material behavior, process parameters, mold design, or machine conditions. Understanding how these factors interplay will enable us to prevent inevitable offending defects instead of just reacting to them. Over the years, we have established that most injection-molding-related defects are linked with a combination of poor temperature management, inconsistent pressure, and mold wear. Addressing all of these factors early on improves cycle time, part precision, and, above all, reliability.

1. Short Shots

Short shots occur when the mold cavity isn’t fully filled. This can result from low injection pressure, poor venting, or material that cools too quickly.

How we fix it:

We increase injection speed, check for blocked vents, and ensure the melt flow index suits the part geometry. Our team also evaluates gate locations to ensure resin flows evenly. This forms a key part of our ongoing troubleshooting injection molding strategy.

2.Sink Marks

Sink marks usually occur in thicker sections where the material shrinks unevenly. Usually, injection defects affect the aesthetic appearance and performance parameters of the part.

- Our approach to the solution: Increase packing pressure; elongate the hold time; and ensure that ribs are properly proportioned to walls for good strength and stability. If required, we can modify the mold steel for better uniform flow. These steps are mandatory considerations for the molding problem and solution across our company.

3. Warpage

Warpage means the bending or twisting of the part after ejection. It is caused when cooling is uneven or when there are internal stresses.

- How we correct it: We make sure the cooling channels are uniform, set the right melt temperature, and balance the flow to fill the mold evenly. Our engineers study and analyze material shrinkage behavior for stable, repeatable output production, which coincides with the entire troubleshooting injection-molding workflow.

4.Flash

Flash appears as the thin, tenuous excess material along the parting line or areas designated for ejection. The condition arises as a result of inappropriate escape of the melt owing to high pressure or misalignment of the mold.

- Our corrective action: We check clamp force with mold examination and parting line flatness, and fine-tune injection pressure. Routine preventative maintenance is what saves us from these injection molding defects.

5. Burn Marks

Burn Marks are formed by dark discoloration due to entrapped air or overheated polymer.

Our approach to mitigating the burn is to improve the venting, reduce the melt temperature, and slow down the injection speed. The runners and gates are designed to ensure smooth flow with no air compression from our side. These adjustments come directly from our expanding knowledge of molding issues and solutions collected from years of production experience.

6. Weld Lines

Weld lines form where two melt fronts meet and fail to fuse completely.

- Our fix: We increase melt temperature, adjust gate placement, and boost injection speed. Sometimes we redesign flow channels for better convergence. By integrating this into our troubleshooting injection molding methods, we improve part strength and appearance.

7. Voids and Air Pockets

Voids weaken a part and usually point to uneven packing or trapped air in the mold.

- Our routine practice: We adjust things like holding pressure, cooling time, and gate size to keep the process stable. Moisture is another key factor, since excess moisture can create bubbles in the finished part.

8. Surface Imperfections (Flow Lines & Jetting)

Surface defects reduce cosmetic appeal and may signal turbulence or inconsistent resin flow.

- How we correct it: We fine-tune the gate size, raise the melt temperature, and make sure the material flows smoothly into the mold. These small but important adjustments help keep our defect rate low.

Best Practices for Preventing Future Defects

Over time, we’ve found that stopping problems before they happen is much easier and cheaper than fixing them afterward. Here’s what we rely on:

- Material quality checks: Moisture analysis and resin handling routines.

- Persistent machine calibration: Pressure sensors, heaters, and screw conditions verification.

- Optimized cooling layout: It cools uniformly, thus preventing warpage and shrinkage.

- Frequent maintenance of molds: Cleaning, lubrication, and repair reduce molding issues and solutions needed within production.

- Scientific molding principles: Parameter setting based on data ensures stable maintenance.

These features highly reduce injection-molding defects and improve the cycle consistency between production lines.

Why Choose Plastic Injection Molds?

At Plastic Injection Molds, we are driven by core values that guide our business and define our commitment to our clients.

Expertise and Experience - With years of experience in the Plastic Injection Molds industries, we have the expertise to deliver custom-designed solutions that meet the most demanding requirements.

High-Quality Products - Our Plastic Injection Molds are made from high-quality materials, ensuring durability, clarity, and long-lasting performance.

Custom Solutions - We specialize in providing tailored Plastic Injection Molds solutions that meet the unique needs of our clients.

Exceptional Customer Service - We provide end-to-end support, from initial consultation to post-delivery assistance, ensuring our clients are delighted with the results.

Do you want to work with us to turn ideas into a reality for plastic molding projects? Call us at +1(647)294-5240 or send us an email at info@plastic-injectionmolds.com. We will work with you fast and easy for you to manufacture with confidence.

Ready to See your Idea For Plastic Injection Molds

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.