Rubber Injection Molding

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

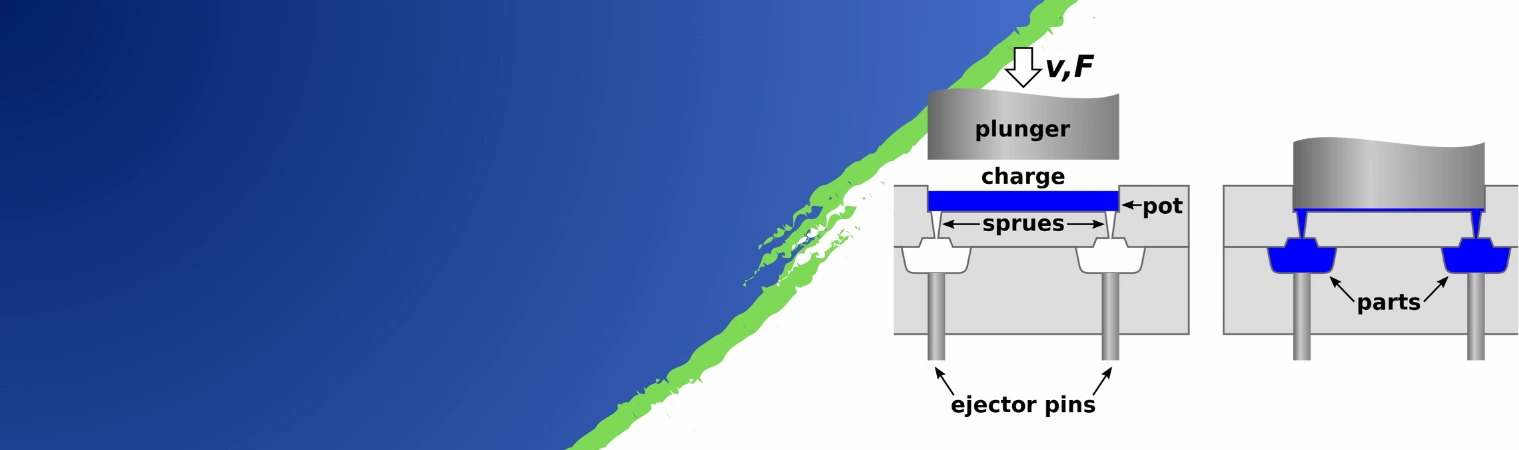

The injection molding process leading to the creation of individual rubber parts is a complicated task. You might have concerns about minimizing stress and using the final parts. The rubber injection molding specialists need to comply with the basic rules and regulations so that the parts are easy to produce and the applications successful. We are an expert dealing with rubber injection molded parts and are thoroughly aware of the basic methods of production.

The rubber injection molding is used for the production of very small parts required for the body panels of automobiles. Here is what you need to know:

From customized and precision rubber tools made to suit the specifications of customers, we modify the proprietary processes to meet your requirements of producing rubber parts. The in-house potential of our company enhances the efficiency of production and help I in delivering the rubber parts quickly.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Advanced Molding Process In Industry

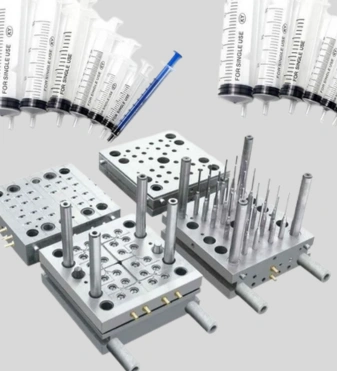

The polymer injection molding process is an excellent method of producing large volumes of plastic parts quickly with high surface quality, and the choice of different resins. Here is what you need to know.

With Polypropylene injection molding, you get the benefit of an inexpensive material possessing high strength due to its semi-crystalline nature. It is used for multiple applications, such as packaging of consumer products and to meet the requirements of plastic components in the automotive industry.

Countries

Industries Served

Projects

Clients

The EPDM injection molding is beneficial as it offers high resistance against UV rays, weathering, aging, chemicals, and ozone. We are an expert dealing with injection molding in different materials, so call us to get the best deals.

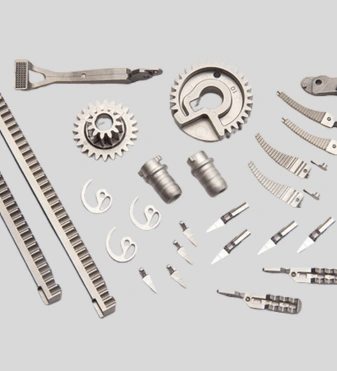

Finely powdered metal is combined with a binder substance to generate a feedstock in the metalworking process known as metal injection molding. The final product is created by solidifying and shaping the feedstock. Metal Injection Molding is the best method for streamlining the manufacturing of items with complicated geometries or high production volumes.

Any variety of metals may be used as the process feedstock, although stainless steel is the most used kind. After the items are molded, the binder material is taken out, and the metal particles are refined to increase the material's tensile strength and durability. When compared to alternative techniques like CNC machining, the metal injection molding process has several benefits. Complex metal objects that are often hard to construct using traditional metal fabrication procedures may now be produced considerably more easily thanks to this technology.

Metal injection molding is excellent for swiftly and effectively creating exceedingly complicated parts. The metal injection molding procedure is quick, simple to replicate, and economical. Intricate pieces may be precisely molded and mass-produced in large quantities in a single process. The best part is that setting up subsequent production runs is quick and simple following your initial run, plastic injection molds would be pleased to supply you with an estimate on your project if you're seeking a partner who offers high-quality metal injection molding services.

The Metal Injection Moulding (MIM) technique offers cost-effective solutions for parts with extremely complicated component geometries by combining the architectural flexibility offered by injection molding polymer with the strength and quality of forged metals. MIM is a more affordable option than conventional metal forming methods including machining, and investment casting.