Injection Molding Cost

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Book a 20 Min. Strategy Call

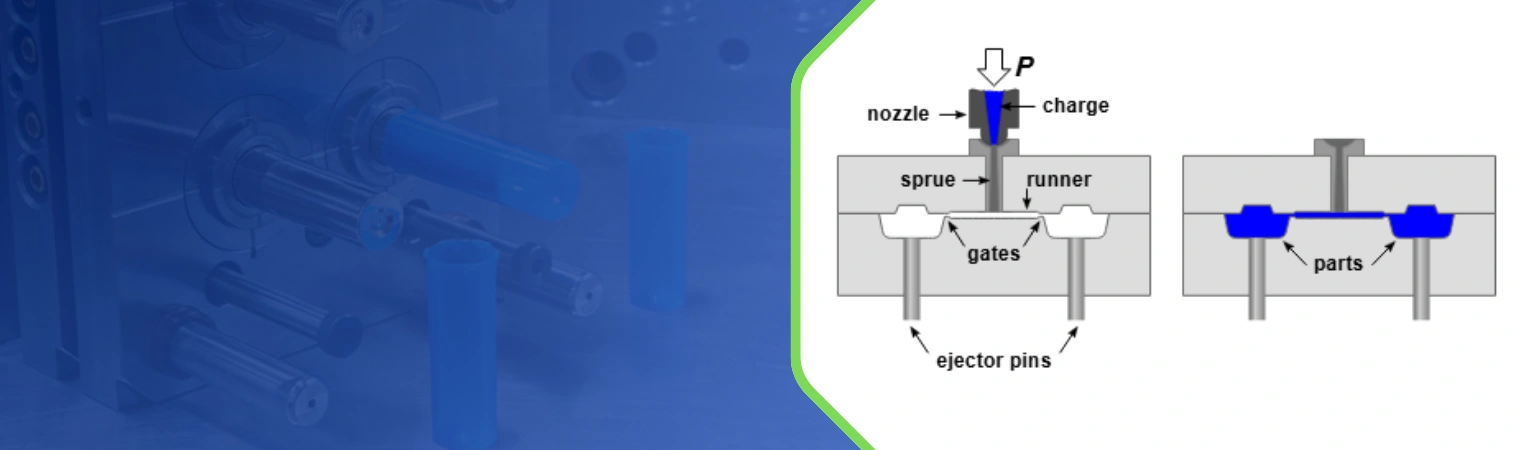

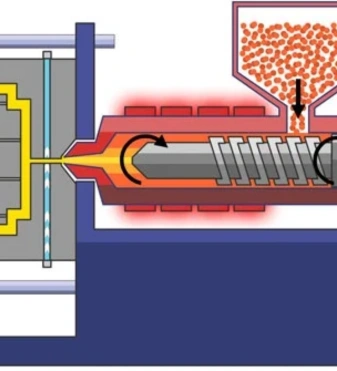

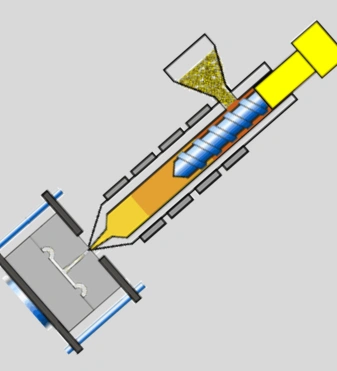

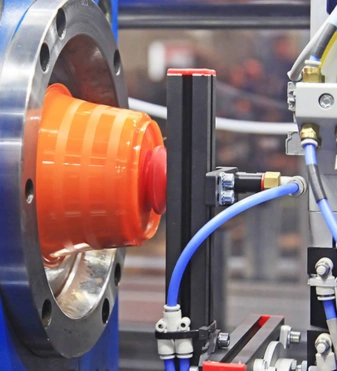

One of the primary aims of any manufacturing company is to reduce production costs. But it is also essential to maintain the quality of the products and not compromising in the production process. The only way to reduce the cost of production is to use the injection molded parts.

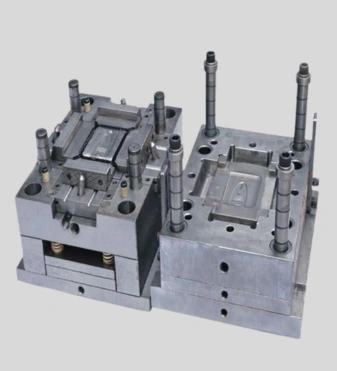

The initial upfront cost to install the molding system may be quite high, but the long-term benefits will be high. For instance, a single tool can manufacture 25,000 parts and more. However, you should understand first how the price reduction happens.

While injection molding is a costly process, if you compare it to 3D printing or CNC machining, low cost injection molding can be a cost-effective solution with its ability to scale and manufacture thousands of parts.

The amount of time necessary for mass production is the chief factor that affects the price of a molding system. So, the complex geometry of the parts indicates that the manufacturing cost is higher. It will be an affordable option if you need to generate simple parts without any advanced smooth finishing or undercuts.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

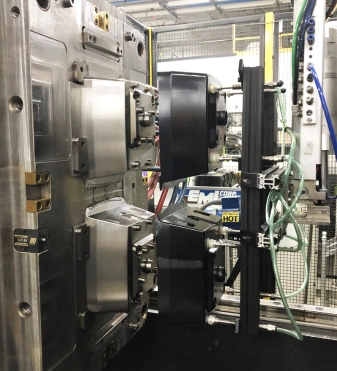

Injection Molding In Industry

If you own a business in the automotive industry, then you have to produce plenty of small parts invariably. The injection molding cost will be much lower than installing a complete manufacturing system involving many machines. The initial investment will be a considerable amount. But it will help to generate small parts in bulk volume.

As you make the prototype through large part injection molding, you can analyze and detect the features that are actually unnecessary for the product. Check out the prototype and think about the features like the company’s logo, textured surface finishing, and molded part numbers. But permanent part numbers are mandatory when you are making military applications ad aerospace machines.

Countries

Industries Served

Projects

Clients

With injection molding small parts, you can actually eliminate maximum human labor as the system can be completely automatic. Automation is the best way to reduce human resource-related costs to the company. The purchasing of the machine is a one-time investment but employing human labor is a recurring expenditure.

How can you earn a profit without increasing production costs? It is by maximizing the volume of production. The low volume injection molding cost is higher than the high-volume production. You can depend on the moulding machines with bulk production of the parts that will immediately increase the profit ratio.

Consult with the reputed injection moulding products manufacturers, and you will understand better the calculations that prove how a company can benefit from investing in molding services. It will also help you to expand by offering the necessary infrastructure to support production pressure.