Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Fastest Delivery and Low MOQ with Money Back Guarantee...

Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

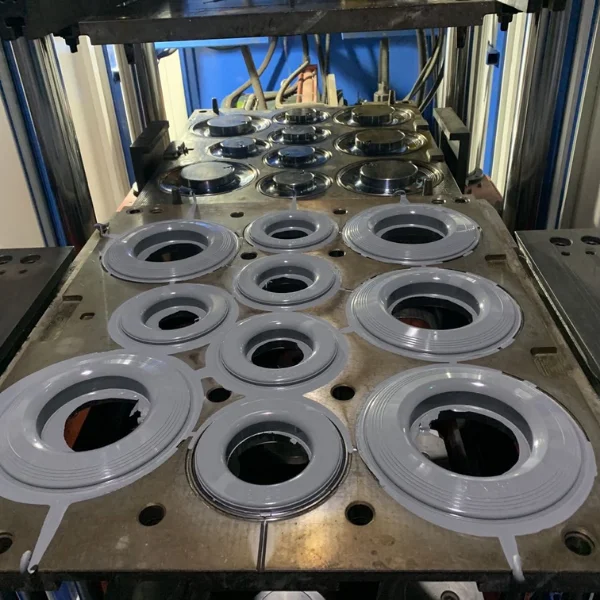

Most of the molds making materials as used over here are manufactured from the natural or even the manmade rubber mainly because of their highest level of flexibility and even the ability to just reproduce some of the extraordinary details over here. But, there are certain molds, which are made using some of the rigid materials like gypsum plasters. Then you have the foam rubber molding procedure to give the materials the ultimate shape as asked for over here.

Some of the common examples of mold rubbers as widely used these days are epoxy, polyurethane and silicone. The foam rubber custom molds are now gaining worldwide popularity because of its ease of usage and also the faster approach towards giving the final results.

The benefits of Molded foam products are as follows.

Structural foaming is the process of adding an inert gas to a molten polymer and injecting it into a standard injection molding tool. The benefits are as follows.

However, for a lightweight, high-strength part that can be manufactured quickly and inexpensively, structural foam may be the way to go. Of course, not all parts are suitable for Molded foam products.

Injection-molded EVA foam is being used in more industries than ever before. EVA foam is a type of closed-cell foam with a fine cell structure and a high degree of cell cross-linking.

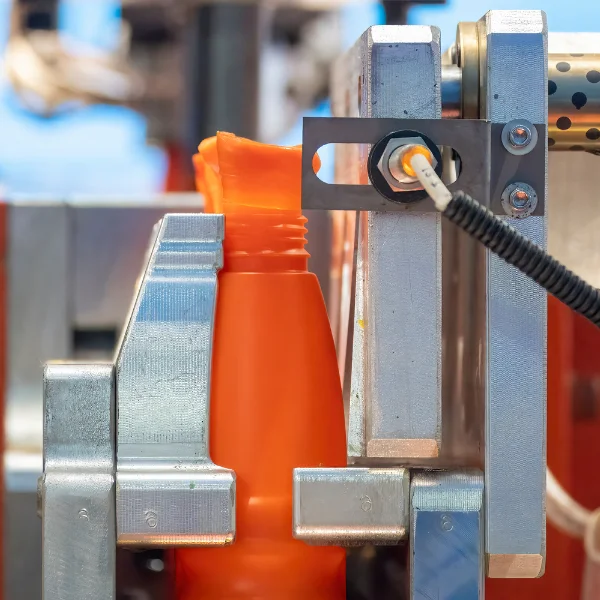

Shape your world with the power of Compression. Compression rubber molding is a molding process that uses custom-made molds to form parts or products from unvulcanized rubber or plastic. The process involves placing material into an open mold cavity, closing the mold, and applying heat and pressure to shape and solidify the material into the desired component.

It can be used to transform various designs into tangible objects for various industries and applications. While this is an ideal production solution for many projects.

Below, we highlight the main advantages and disadvantages of the compression molding process to help you better understand if this is the right solution for your needs. The benefits of rubber compression mold design are as follows.

With the help of back pressure and in proper amount, you are able to give the foam mold making process the next steps further. This high pressure is mainly applied during casting, where the surface finish of the cured foam approaches that of urethane elastomer.

The best part to work with our company in terms of foam mold manufacturing is that we offer the molding results within your set rates. So, there is no need to wait for you to invest a lot of bucks for our items.

The compression molding manner is noticeably easy and easy in comparison to different molding and production processes. For some part designs, this makes it easier for operators to perform and reduces overall production costs.

This tool has fewer infrastructure requirements than tools designed for other molding processes, as the process does not involve injection or transfer cycles.

Low capital costs for making molds, setting up presses, and starting production parts mean compression molding is the most cost-effective way to produce parts in small quantities.

This Compression rubber molding method is ideal for manufacturing large parts that require large amounts of material. Since the material is loaded directly into the mold cavity, there is no limit on the weight of the parts produced, aside from the size of the press and the required tonnage.

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.