Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Fastest Delivery and Low MOQ with Money Back Guarantee...

Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

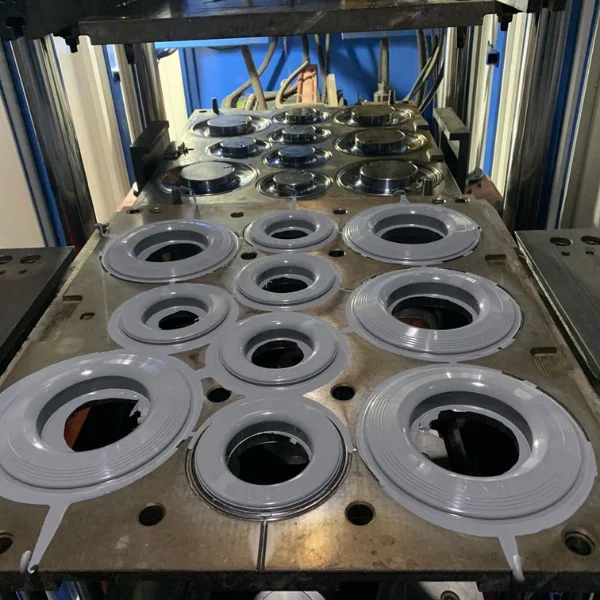

Rubber parts molding is one industry, which is gaining quite some popularity nowadays. Using high grade rubber materials will help in creating the perfect molds, ready to last long. These items are known for their durability, long lasting working effects and so much more. If you are looking for the finest rubber parts manufacturer, you can just give us a call. We have created some of the best rubber molds, which are finally used for creating the parts.

Embark on a journey into the realm of innovation and reliability with the unsung champions of industry – rubber parts manufacturers. Our skilled craftsmen specialize in the creation of a diverse array of components, ranging from essential seals and gaskets to intricate automotive parts. Our expertise lies in the art of molding rubber into shapes that not only fit perfectly but also deliver unmatched performance.

What sets our manufacturers apart is their unwavering commitment to quality. Armed with advanced technology, we meticulously engineer rubber parts that stand the test of time, ensuring durability and resilience in various applications. From the automotive sector to machinery and beyond, our manufacturers play a pivotal role in enhancing the efficiency and functionality of a myriad of products.

In many cases, the need for sealing can be addressed with a standard solution, but some projects may require a more specific design. Only tailor-made molded rubber product manufacturers are suitable in such situations. If you are looking for a detailed and specific solution to a difficult or special application need, using our custom-molded products is the only answer to your engineering needs.

High-quality custom moldings ensure a longer product life and associated components keep working longer. Let's take a look at some of the tangible benefits manufacturers get from using custom-molded parts.

Side-by-side, custom-molded products seem like opposites. Due to their construction, these parts not only offer great flexibility but also improve the accuracy of the finished part. Despite the wide range of material options available, there are the economic advantages of rubber mold manufacturing.

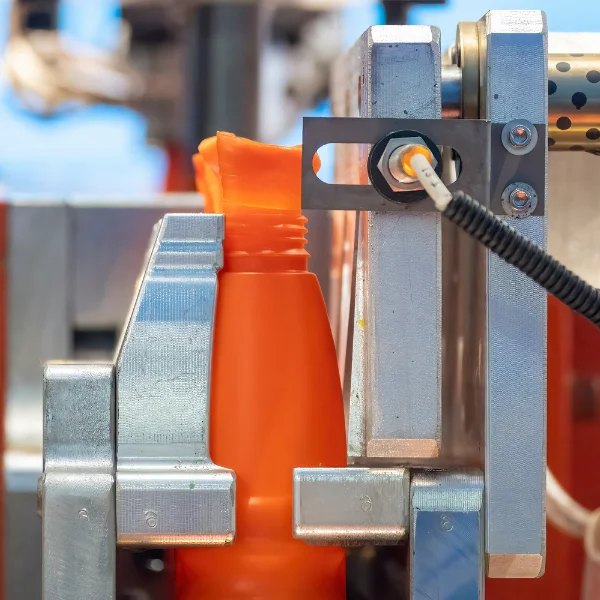

With such a wide variety of designs, materials, colors, and additive options, we can manufacture almost any type of part using our custom injection molding process. Colors can be easily exchanged, especially on plastic injection molding machines.

Reliability

Designing and using custom moldings can improve product consistency by reducing potential errors. Molds allow the finished product to be produced with great precision. No matter how complex your part is, custom molds for rubber ensure the most accurate and repeatable molds for your production.

Budgeting

Injection molding is one of the most efficient methods for manufacturing machined plastic parts. This means you can produce more precise parts in the same timeframe compared to other methods. Molding machines often use auto-start molds to streamline operations and keep production running smoothly.

It is really important for you to check out for the best rubber component manufacturers in town. For that, you have to work a bit hard in this regard.

For creating the outstanding rubber parts for multiple uses, you need to get hands on the rubber die first. This die is more like a basic structure, which will be the ultimate shape of the molten rubber parts after compression. You can join us as your rubber die manufacturers over here.

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.