Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Fastest Delivery and Low MOQ with Money Back Guarantee...

Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

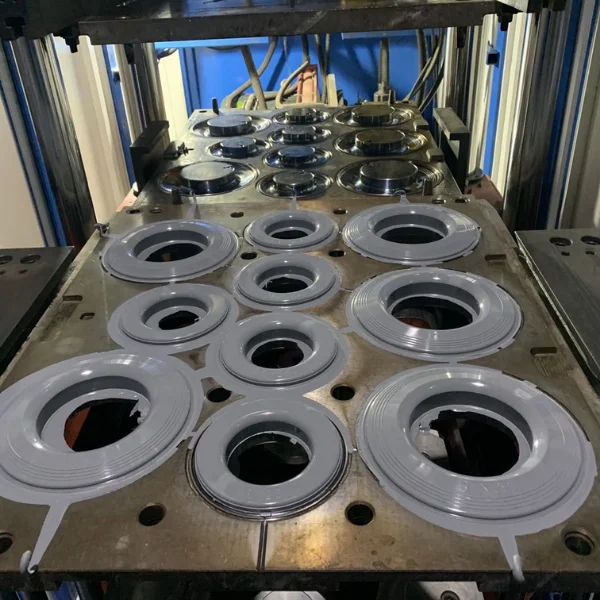

An industry runs on multiple items, which are together used for making a revolutionary invention in the market. Now, the items that are used in an industry are not that easy to make. To give that proper shape and size to the industrial parts, there needs to be a mold. Liquid metals are passed into the molds and then cools down to create the final result. So, the first thing you need is the mold. There are variations associated with Industrial Rubber Molds components and you will get those from reliable online sessions. Join us for the best mold options.

You are likely to spend quite some bucks for the industrial rubber molds. Therefore, it is always mandatory for you to get along with the best Industrial Rubber Molds Manufacturers in town for help.

Researching has let you come across multiple Industrial Rubber Molds Suppliers and you need to choose the best one among the lot. That’s why we are likely to be the suppliers you can trust always.

In this highly competitive market, what are the characteristics that make us a reliable industrial rubber company of all time? For that, you have to get down to these points.

In this blog, we will examine the process of finding the best industrial rubber mould maker for your business. We will discuss the factors that need to be taken into account when selecting a manufacturer, such as product quality, delivery times, pricing, and customer service.

We will also provide tips on how to evaluate and compare different manufacturers, so you can make an informed decision. By the end of this article, you’ll have a better understanding of the different aspects that go into selecting the best industrial rubber products manufacturer. You’ll be able to make a decision that best suits your business needs.

Industrial custom rubber mouldings are items made from rubber used in various industrial applications, such as construction, manufacturing, and engineering.

Access to a wider range of products and services: Working with a manufacturer allows you to access a wider range of products and services than you would from a distributor. Manufacturers often have a greater selection of tools, materials, and technologies that can help you achieve your goals.

Cost savings: Manufacturers can produce rubber products in bulk and pass the savings on to their customers

The Future of Rubber Moulded Products

In this blog, we will explore the environmental benefits of using rubber-moulded products in manufacturing and how this technology is becoming the future of the industry. We will discuss the emerging trends of rubber-moulded products and the innovations that are pushing this field forward.

Make sure to not waste any more of your time and catch up with us for the finest Industrial Rubber Molds of all. We are so pumped to help you and will always offer the best rubber molds you could have asked for. Even if you have a limited budget or a personalized idea, we will ensure that our molds cover all of that with ease.

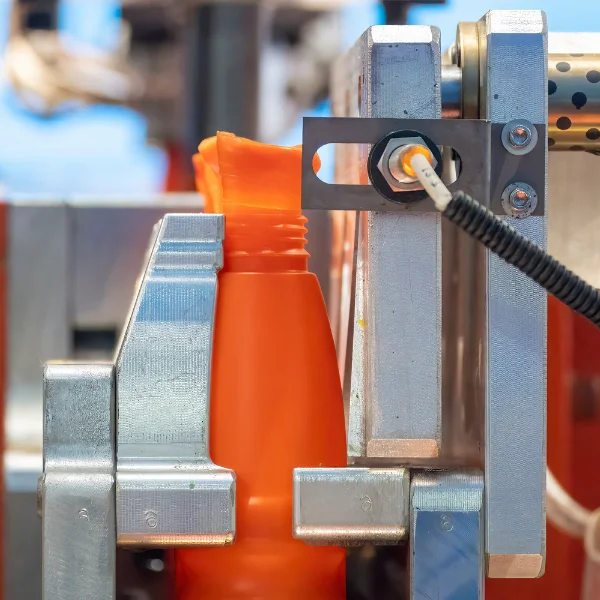

As you know, industrial moulded rubber products are one of the most popular means of manufacturing complicated plastic parts. It is a fast and cost-effective way to produce high-quality products.

Industrial Rubber Products Manufacturers help to create products that involve the creation of rubber moulds by pouring liquid rubber over an existing object. The process begins with a design, which can be either computer-generated or hand drawn.

You may be surprised to learn that the industry has grown faster than expected, and it’s expected to grow even more in the future. The rapidly expanding market has led to many new companies being created over the past decade. Some examples of these include:

Rubber moulded products manufacturers help in the manufacturing process to produce a wide variety of products, including car parts, furniture, and Packaging. The automotive industry uses rubber moulds to make doors and bumpers for cars. This can be done by using injection moulding or compression moulding techniques depending on your requirements.

Foam Rubber custom moulds are increasingly being used in manufacturing processes as an alternative to more traditional materials. They offer a range of environmental benefits, such as reduced energy consumption and emissions, improved resource efficiency, and increased recyclability.

The use of foam mould-making products in manufacturing is becoming increasingly popular as a way to reduce the use of toxic materials. Rubber moulded products are made from sustainable materials and are non-polluting and recyclable, meaning they are an environmentally-friendly alternative to traditional manufacturing materials. For more details,

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.