Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Fastest Delivery and Low MOQ with Money Back Guarantee...

Custom Designs & Quality

Rubber Molded Products

Low MOQ

Non Sticky

Total Design Support

Lab Tested Food Safe

Within this current field of rubber door molding maker manufacturers firms, our company is one of the leading suppliers and manufacturers of the finest items for practically all the industries out there in the market. Our company is known to have decades of experience with all the forms of rubber moldings. Companies like us are known to design and further develop various rubber parts, mostly in close cooperation with the clients for sure. So, we are always there to help you in solving any of the conceivable sealing issues. With us by your side, possibilities are quite endless in this regard.

It is always necessary for us to start the procedure with the prototype of the rubber moulding practices over here. We can always produce a proper prototype for you just lie you have asked for it.

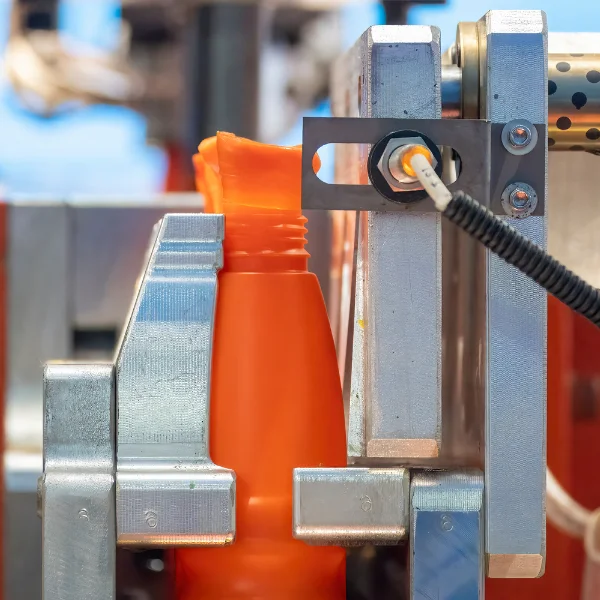

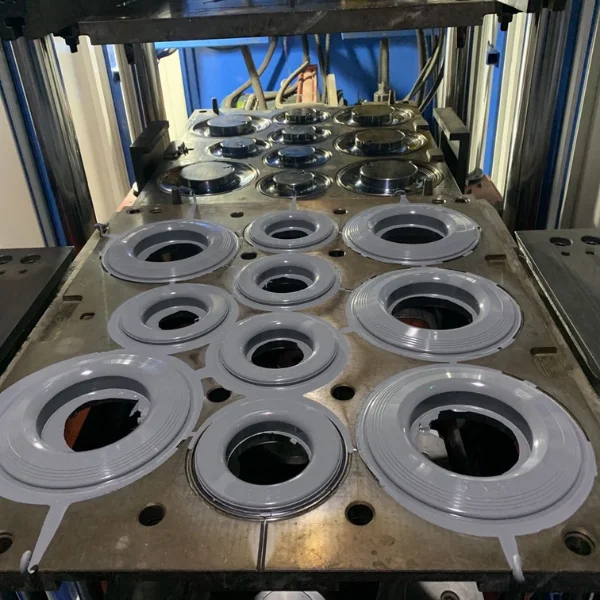

In the beginning, a mold cavity is created of the desired size of the rubber mold. Then the liquid rubber i.e. heated at high temperature, is filled in it. Then, manufacturers of industrial rubber molds allow the rubber to get solidified and hardened, creating multiple copies of it.

Manufacturers use various techniques like injection molding, compression molding, and transfer molding. After manufacturing these molds, they are supplied via various transportation mediums to the customers according to their requirements.

We already have several years of experience in the rubber molding industry and have made many customers happy during this period. We have learned from our failures and kept ourselves constantly evolving. We have top-level teams that include highly skilled engineers and other professionals.

We provide high-quality latex molds to our customers.

Latex mold making refers to the process by which latex molds are created. Latex molds are highly useful in creating replicas of various objects. These molds are made from liquid latex, a naturally occurring rubber material. These molds can prove to be very useful in the arts and crafts industry to create replicas of various sculptures, ornaments, and other decorative items.

Latex molds are a great option for creating detailed concrete molds. To prepare latex molds, first, an object is prepared, of which the mold is going to be created. Then the latex is added according to the manufacturer’s instructions.

To create Latex molds for concrete, further, the release agent is added which prevents the object from getting stuck to the latex. Once the latex dried up, we reinforce it with the help of fiberglass. Once the reinforcing layer dries, we remove the model from the mold. Then the concrete is added and then removed from it. In this way, the model gets prepared.

The main way to create the rubber molds is by taking help of the noted rubber mold maker in town. If you are looking for the best maker in this regard, you can log online and get some help over here for sure.

Once you have us by your side, chances are high that you will end up with the finest molded rubber bumpers of all time. There are so many of them available in the market and you can easily choose the one you like the most among the lot.

We have several years of experience and have won the hearts of thousands of customers. We are well-known for providing high-quality latex molds at a reasonable cost. Our latex molds are used on several occasions and especially during artistic events.

Latex mold making is a time-consuming process, but we deliver our work under the time limit provided to us, along with customization.

137-1140 Burnhamthorpe Rd. W | Mississauga ON L5C 0A3 | Canada

© RUBBER SILICONE MOLDS. All Rights Reserved.