Aerospace & Defense

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

- Home

- Aerospace Precision Rubber Extrusion Components

High-Precision Aerospace Extrusion for the Aerospace Industry

In modern aircraft and spacecraft, dealing with the effects of constant vibration and motion is extremely important. Aerospace rubber extrusions are crucial for making sure that various systems in airplanes and spacecraft are reliable, flexible, and safe. These bellows are made to handle incredibly high temperatures, a lot of pressure, and strong vibrations. These bellows are used in hydraulic systems, around the engines, and even in ventilation systems.

At Custom Rubber Extrusion, we're experts in designing and manufacturing high-quality bellows for the aerospace industry. We use premium materials that can withstand fuel, oil, ozone, and UV exposure, ensuring our bellows work reliably even in tough aerospace conditions. Our bellows basically act as protective covers and shock absorbers for important aircraft parts.

Every aerospace project is different and has its own specific needs. We blend cutting-edge technology and years of hands-on experience to provide flexible industrial rubber bellows for aerospace applications. Our design experts work closely with engineers to develop customized bellows for crucial aircraft systems, guaranteeing to improve overall aircraft performance.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Rubber Extrusion Solutions with Proven Expertise

1395 projects & 690 happy clients.

At Custom Rubber Extrusion, our focus is on designing and manufacturing Extrusion products specifically designed to meet the individual needs of each of our customers. We have a decade of experience in the industry, during which we've successfully delivered over 1395 projects for a wide range of industries, and are proud to have served more than 690 happy clients.

We customised every Extrusion to meet your exact requirements, guaranteeing durability, dependability, a perfect fit, and top-notch performance. Whether it's for the automotive, oil and gas, construction, chemical, or general industrial sectors, our products are made with precision to handle the toughest conditions.

5+

Countries

11+

Industries Served

1395+

Projects Completed

690+

Clients

RUBBER BELLOWS INDUSTRY

Industry Served

Why Choose Us

Custom Solutions of Aerospace Rubber Profiles

Aerospace rubber bellows are customised to handle the demanding technical and environmental conditions of aviation. These bellows are engineered with very accurate dimensions to guarantee they fit correctly and perform reliably. The key reasons to choose our defense-grade rubber profile seals are:

- Custom Fit: Every bellow is customised to fit the specific aircraft requirements for pressure tolerance and movement compensation.

- Enhanced Durability: Our custom bellows perform durably and dependably, even in high altitudes and intense atmospheric pressures.

- Material Choice: Our bellows are made from silicone or Viton because they can handle temperature shifts, fuel exposure, and tough mechanical stress.

- Quality Assurance: Every single bellows goes through rigorous quality checks, guaranteeing that our bellows are fit for the aircraft system.

Our Expertise for Aerospace Seals

Our high-performance rubber seals manufacturer for aircraft is known for our innovation and the reliable bellows we create. By combining our manufacturing expertise and material understanding, we ensure our bellows work as effectively and dependably as possible. We follow a careful process to manufacture the perfect high-performance bellows for aerospace applications:

- Material selection: We meticulously choose EPDM or silicone material to meet strict aerospace industry quality requirements.

- Design and Engineering: We design and manufacture bellows to endure high pressure, vibration, and extreme temperatures for long-lasting reliability.

- Precision Molding: With top-notch molding methods, we make bellows with uniform wall thickness, precise measurements, and smooth surface finish.

- Curing and Finishing: We use heat curing to enhance the elasticity and strength of the bellows so that they can handle high temperatures.

- Quality Checks: To ensure quality, we conduct thorough testing to check for air leaks, resistance to pressure, and long-term durability.

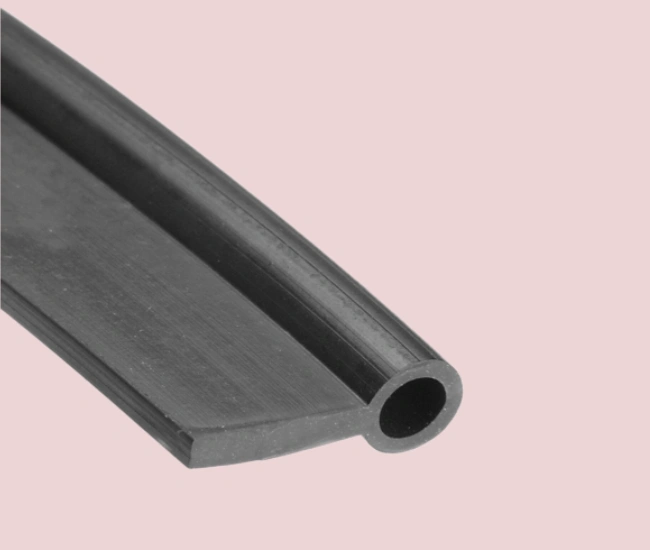

How is Rubber Channel for Aerospace Useful?

Silicone bellows are a popular choice in the aerospace industry because they hold up really well against heat, cold, and harsh chemicals. The silicone stays flexible across a broad range of temperatures, usually from around -60°C to +230°C. This makes them great for engines, air ducts, and air management systems in aircraft. They're also quite durable, so they maintain their elasticity even at high altitudes where the pressure and temperature change all the time.

Whether they're used in cabin pressure systems or exhaust parts, our aerospace rubber channels & trim help to cut down on vibration, create a tight seal, and stay strong and reliable for a long time. Ultimately, these bellows protect important parts and systems of aircraft from potential harm and help them work smoothly and reliably in the toughest environmental conditions.

Advantages of Aerospace EPDM Extrusion

Our EPDM high temperature extrusions are specifically designed to handle the changes in size caused by temperature from mechanical sources and the fluctuating pressures. They are essential for keeping aerospace systems working properly and stopping leaks in engines, exhaust systems, and fluid lines. The benefits of these flexible bellows are:

- Thermal Expansion Control: These bellows handle the expansion and contraction due to the drastic temperature changes.

- Vibration Absorption: They help cut down on vibrations of connected parts which protects delicate aerospace components.

- Pressure Resistance: They can handle tough pressure situations of fuel lines, exhaust pipes, hydraulic systems, or air ducts.

- Durability: They withstand wear and tear, damage, and corrosion, providing long-lasting durability even in the demanding applications of aerospace.

Our Expertise as a Military Spec Rubber Gaskets Manufacturer

As a military spec rubber gaskets manufacturer, we blend our modern technology and expertise to manufacture our bellows precisely. Our manufacturing process includes accurate molding, thorough quality checks, and performance tests to guarantee that every bellows complies with global marine regulations. Our customization capabilities include:

- Material Selection: We use top-quality materials like various rubber types or industrial-grade silicone that can handle high temperatures.

- Size & Shape: We make bellows in unique diameters, lengths, and wall thicknesses, ensuring they accurately fit the marine systems

- Reinforcement: We add fabric reinforcement to make your bellows even stronger for resisting tough marine environments.

- Design Assistance: Our design team collaborates with you to create custom designs for your specific needs.

Contact Us for Your Needs

Aerospace rubber bellows are really important for keeping aerospace systems safe and secure. They can withstand extreme heat, pressure changes, and vibration, providing tight and efficient sealing in various aircraft systems. Because they're made from rubber and silicone, they can stand up to corrosion and harsh environmental damage, which is key for long-lasting performance in aerospace. Contact us today to discuss any type of aerospace bellows you may have, whether it's flexible rubber bellows, silicone aerospace bellows, or aerospace quality tubing & hoses, and we'll provide you with the right solution. We make precisely-engineered bellows for aerospace applications with the highest standards for quality and safety, so you can count on them to reliably protect aircraft systems.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.