- Home

- Rubber Extrusion Process Guide

Rubber Extrusion Process: What You Should Know

Rubber extrusion ranks among the most common manufacturing methods for producing continuous rubber products such as seals, gaskets, profiles, tubes, cords, and weatherstrips. In case you are engaged in product design, engineering, procurement, or maintenance, knowledge of the rubber extrusion process will assist you in selecting suitable products, communicating effectively with manufacturers, and saving money by not making errors. Here is an easy and simple manual outlining the essential information about rubber extrusion, starting with the key process steps involved, its practical advantages, and common applications.

What Is Rubber Extrusion?

Rubber extrusion is basically a method where a raw (non-vulcanized or uncured) rubber mixture is pushed through a specially shaped hole called a die to get a continuous profile having the same cross-section.

1.EPDM / Sponge Rubber: One of the main choices in the production of rubber products is EPDM, which is mainly used for outdoor and weather-exposed applications, and is therefore suitable for a long lifespan.

- To illustrate the point, one can compare it with squeezing toothpaste out of a tube, the shape of the opening (die) determines the shape of the product.

- Most of the time, after rubber extrusion, the rubber is also cured (vulcanized) to be able to retain the characteristics that come with it, like elasticity, strength, and wear-resistance.

Key Steps in the Rubber Extrusion Process

a) Material Selection and Compounding

The production requires recognizing the correct rubber compound at first depending on the application characteristics such as temperature range, chemical exposure, flexibility, and hardness. Compounding is a process of mixing base rubber with fillers, plasticizers, curing agents, and additives (such as UV stabilizers or flame retardants) to achieve the desired performance.

b) Feeding and Pre-Heating

Most of the time, the compounded rubber comes in strips or slabs. These pieces are put into the extruder's hopper and slowly pulled in by the screw. Pre-heating warms up the rubber, thus, it becomes more convenient to push it and to mix it in the extruder barrel.

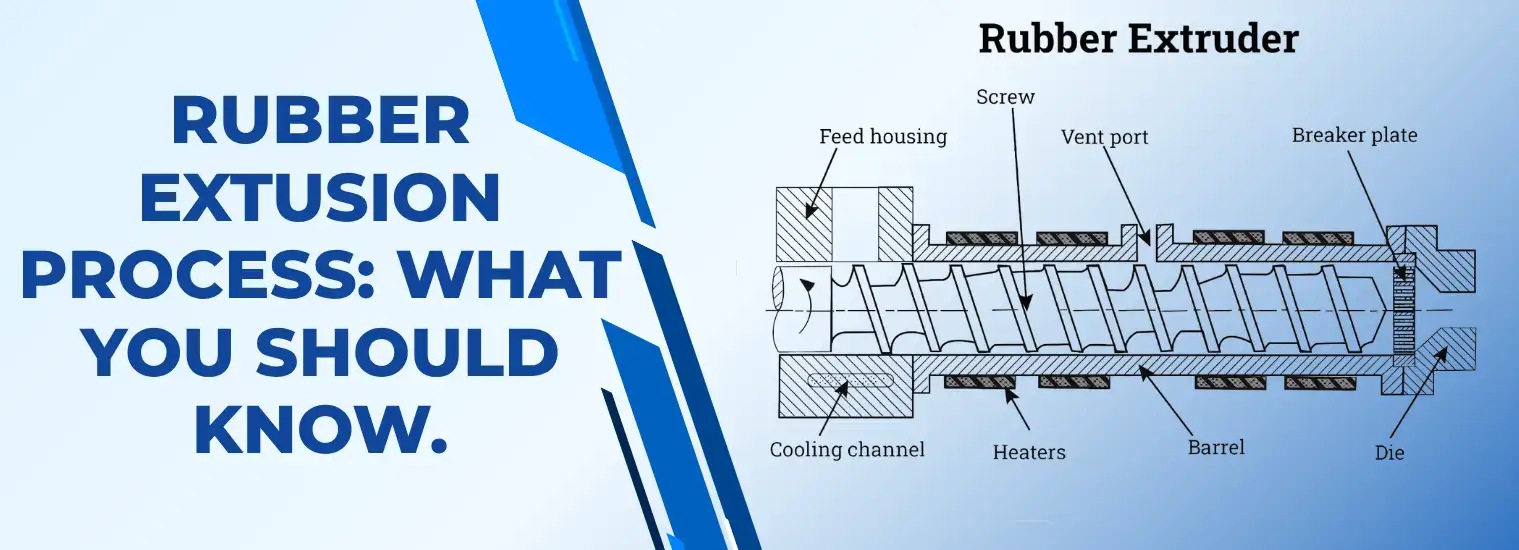

c) Screw Extrusion

A turning screw at the extruder chamber impels the rubber to the front under very high pressure and a temperature kept under control. Throughout this process, the material is mixed, compressed, and homogenized to remove air and achieve uniform properties.

d) The Shaping

The heated rubber is forced through a metal die of precise dimensions that essentially determines the cross-sectional shape of the rubber. The die layout has to take into account the expansion, contraction, and flow properties so that the final heat-cured profile is of the correct size.

e) Curing/Vulcanization

The rubber just made by extrusion can be soft and not yet fully functional. It has to be cured or vulcanized to be able to hold its final strength and elasticity. Depending on the material and production facilities, curing is possible in hot air ovens, salt baths, steam autoclaves, or continuous microwave/infrared tunnels.

f) Cooling and Sizing

The profile is chilled (usually by air or water) to fix the dimensions after mending. If the tolerances are very close, sizing tools or calibrators can be used to ensure cross-section accuracy and lessen the effect of warpage.

g) Cutting, Splicing, and Finishing

By the use of different methods, the chilled extrusions are cut to the desired length, coiled for further operations, or spliced to form endless rings or frames. There are also some additional steps that may consist of punching holes, applying adhesives, surface finishing, printing, or quality nspection.

Advantages of Rubber Extrusion

- Continuous Length: Perfect for long runs such as door seals, frame gaskets, and piping.

- Customizable Cross-Sections: It is possible to manufacture complex shapes, hollow sections, and multi-cavity profiles.

- Material versatility: Various rubber types can be extruded to suit different environments.

- Consistent quality: If the tooling and process control are done properly, extrusion can produce uniform profiles for long runs.

Typical Applications of Extruded Rubber Products

Rubber extrusion finds its application in various industries and in products which are commonly used in day-to-day life:

- Automotive: Seals for doors and trunks, window seals, hoses used under the hood, and grommets for wiring.

- Construction and Building: Gaskets for windows and doors, seals for curtain walls, and profiles for expansion joints.

- Electronics and Electrical: Cable leading, insulation sleeves, gaskets for enclosures.

- Marine and Transportation: Profile for fenders, seals for hatches, anti-vibration mounts.

- Industrial Machinery: Tubing, protective covers, vibration control profiles, and sealing strips.

- Consumer Products: Gaskets for refrigerators, seals for appliances, protective edges.

Why Choose Custom Rubber Extrusion?

At Custom Rubber Extrusion, we are driven by core values that guide our business and define our commitment to our clients.

Expertise and Experience - With years of experience in the Extrusions industries, we have the expertise to deliver custom-designed solutions that meet the most demanding requirements.

High-Quality Products - Our ExtrusionsExtrusions are made from high-quality materials, ensuring durability, clarity, and long-lasting performance.

Custom Solutions - We specialize in providing tailored Extrusions solutions that meet the unique needs of our clients.

Exceptional Customer Service - We provide end-to-end support, from initial consultation to post-delivery assistance, ensuring our clients are delighted with the results.

Conclusion

Rubber extrusion is one of the most versatile and efficient production processes that allows the creation of continuous, custom-designed rubber products. Knowing the extrusion process, fundamental steps, available materials, curing methods, and finishing options, you will be able to make better choices for your projects and ensure the best results. In case you require just basic tubing or complicated multi-cavity profiles, proper communication with a skilled rubber extrusion company will facilitate the transformation of your design into a durable extruded products.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.