Rubber Channels

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

- Home

- Rubber Edge Channel

Rubber Edge Channel Applications and Manufacturing Solutions

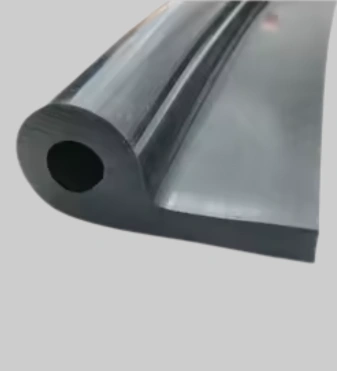

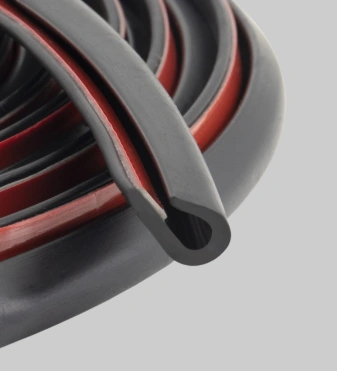

Rubber Edge Channel is a vital product that is widely used in various industries to protect sharp edges, provide secure sealing, and enhance the overall safety of equipment and vehicles. These channels are specifically designed to fit over metal, glass panels, or plastic edges, ensuring great resistance to weather, chemicals, and temperature variations.

At Custom Rubber Extrusion, we manufacture durable and high-quality rubber edge channels with long service life and flexibility. As one of the leading rubber edge channel manufacturers, we make sure our every product meets high standards of quality and performance. We focus on providing customised solutions to meet different industrial applications from automotive and construction to marine and electrical.

Our manufacturing process involves advanced rubber extrusion techniques that help us manufacture strong, flexible, and reliable edge channels. We make these seals in a variety of shapes, sizes, and materials like EPDM, silicone, and neoprene, depending on environmental conditions. We also carefully inspected our rubber product to ensure it provides superior sealing, protection, and longevity.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rubber Channels

Our Products

Your Trusted Rubber Edge Channel Extrusion Manufacturers

As one of the trusted rubber edge channel extrusion manufacturers, we use modern extrusion processes to make continuous rubber profiles with uniform size and shape. We make sure each of our rubber edge channels meets industry standards for performance, sealing, and protection. Here are the key reasons why our customers choose us:

- Custom Design Support: We can custom-design the rubber edge channels according to the application requirements.

- Material Expertise: We wisely select the right material to ensure the precise strength, flexibility, and resistance required for each specific use.

- Precision Extrusion: We use advanced extrusion processes for making dimensionally accurate rubber products with tight tolerances.

- Prototype to Production: From initial prototypes to mass production, we provide end-to-end solutions.

- Quality Assurance: Every product is thoroughly tested for dimensional accuracy, hardness, and tensile strength.

- Customer-Centric Service: We provide fast response, timely delivery, and technical guidance for every order.

Advantages of Industrial Rubber Edge Channel Profiles

We provide industrial rubber edge channel profiles that are designed to last even under harsh environmental conditions. These profiles are mainly used in automotive, industrial machinery, or equipment, and construction projects to protect metal, glass, and plastic surfaces from external damage. The key advantages of using our industrial rubber profiles:

- Edge Protection: Our industrial rubber profiles protect sharp edges from corrosion and damage, ensuring long-lasting durability.

- Vibration Control: They absorb shocks and vibrations, minimizing noise and reducing mechanical stress on connected parts.

- Weather Resistance: These seals can highly resist UV rays, ozone, and temperature variations without cracking or fading.

- Safety and Comfort: By covering sharp edges, these profiles help prevent injuries and create safer working environments.

- Easy Installation and Maintenance: They are extremely flexible and lightweight, and thus can be installed easily and quickly.

Countries

Industries Served

Projects

Clients

Manufacturing Process of Custom Rubber Edge Channel

The manufacturing process of custom rubber edge channels involves careful material selection, precision extrusion, and quality inspection to make sure that the rubber channels meet the high standard of dimension, durability, quality, and performance. The key steps of the manufacturing process are:

- Material Selection: We start by selecting the right rubber material (EPDM, Nitrile, Silicone, Neoprene) based on temperature and application needs.

- Compounding: The raw rubber is mixed with additives to enhance hardness, flexibility, and durability.

- Tooling and Die Design: We then design a custom die to achieve the required channel shape and dimensions.

- Rubber Extrusion: After that, the raw rubber is pushed through the die under controlled pressure and temperature to form the precise channel profile.

- Curing / Vulcanization: The extruded rubber is then cured using heat to give the profile extra strength and flexibility.

- Cutting and Trimming: The extruded edge channel is cut to the required lengths, removing any excess material for a clean finish.

- Quality Inspection: The rubber is then tested for quality, dimensional accuracy, and smooth surface finish.

- Packaging and Dispatch: Finally, the finished custom rubber edge channels are carefully packed and delivered safely on time.

Why Choose Us?

As a leading rubber edge channel maker, we aim to provide high-quality and durable rubber products for various industries. We use modern rubber extrusion technology, top-grade materials, and follow strict quality control measures to deliver channels that perform exceptionally well in demanding environments. We are dedicated to providing complete support, from material selection to profile design, ensuring the perfect fit for your applications.

Whether you need small batches or large quantities, we can handle orders of all sizes with consistent quality and timely delivery. With years of experience, technical expertise, and a customer-centric approach, we ensure to provide rubber edge channels with a long service life at a competitive price. We can provide both standard and custom design channels in any shape, thickness, length, or hardness to perfectly match your specific project needs.

Contact Us for Your Needs

Rubber edge channels are essential protective covers used across industries for protection and long-lasting performance. If you are in search of rubber edge channel companies that design and manufacture high-quality channels for your project, then contact us today to discuss your project requirements. Our expertise in rubber extrusion, advanced manufacturing capabilities, and commitment to quality guarantee that every edge channel we manufacture meets your exact specifications. With strong technical support and fast turnaround times, we always deliver excellent sealing solutions for any type of industrial application.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.