- Home

- Rubber Extrusion Manufacturing Process

Manufacturing Process of Rubber Extrusion

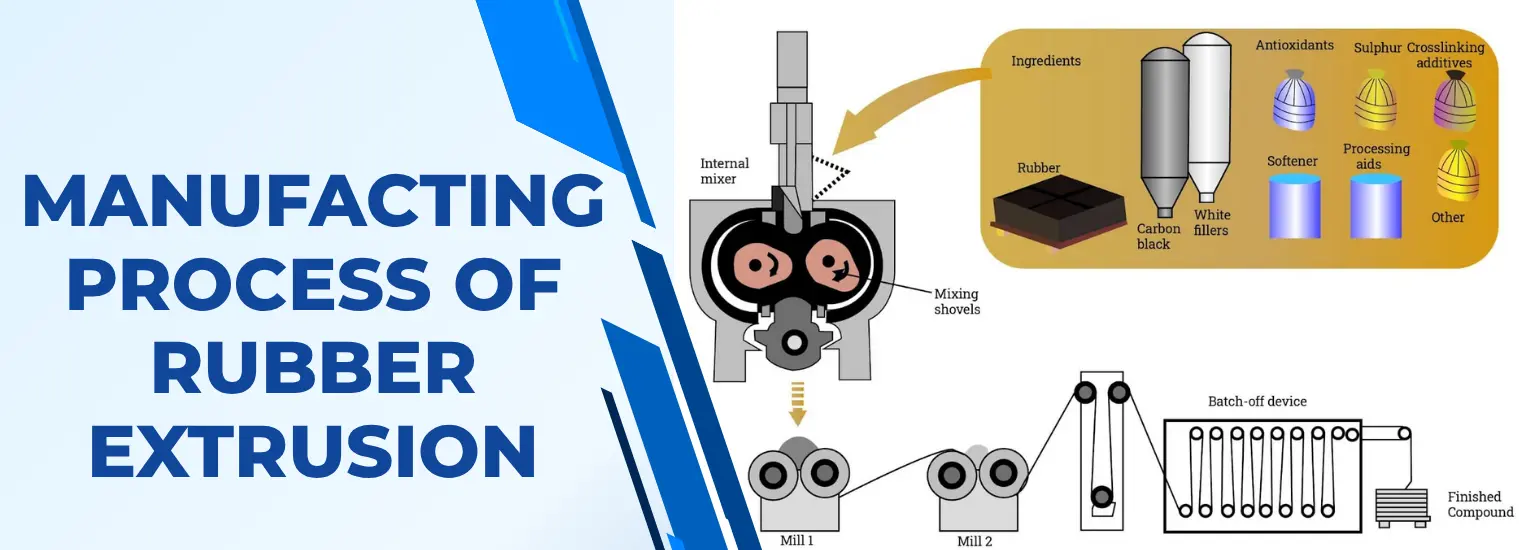

The manufacturing process of rubber extrusion is a step-by-step method of forcing uncured rubber through a shaped die to create continuous profiles like seals, tubes, cords, and gaskets. It is widely used in automotive, construction, electrical, and industrial applications.

What Is Rubber Extrusion?

Rubber extrusion is a process where soft, unvulcanized rubber is pushed through a die opening using an extruder machine. After extrusion, the rubber is cured (vulcanized) to give it strength, elasticity, and long-term performance. The shape of the die decides the final profile – for example:

- Solid profiles (D-shapes, P-shapes, U-channels)

- Hollow tubes and hoses

- Cords, strips, and weather seals

1. Selection and Compounding of Raw Rubber

The first step in the manufacturing process is material selection and compounding.

a) Choosing the Rubber Type

Each material has different properties like temperature resistance, hardness, flexibility, and chemical resistance. The rubber compound is chosen based on the application and working conditions. Common materials include:

- EPDM – for weather, UV, and ozone resistance

- Silicone – for high-temperature and food-grade applications

- Neoprene – for moderate oil and weather resistance

- Nitrile (NBR) – for oil and fuel resistance

- Natural Rubber (NR) – for high elasticity and abrasion resistance

2. Pre-Forming and Preparation of Rubber

After compounding, the rubber has to be prepared in a convenient shape for feeding into the extruder. Proper thickness and width are maintained to match the extruder screw size and capacity.

a) Slab or Strip Forming

- Sheeted out into slabs or

- Cut into strips for easier handling

b) Conditioning and Storage

The rubber strips are often cooled and rested so that internal stresses are reduced. They are then stored properly, usually wrapped or covered, to avoid dust and contamination. This step supports consistent feeding and better extrusion quality.

3. Feeding the Extruder

The extruder is a key machine in the rubber extrusion manufacturing process. It typically consists of:

- A hopper (to feed rubber)

- A heated barrel

- A rotating screw

- A head and die assembly

a) Loading the Rubber

Rubber strips are manually or automatically fed into the hopper. The screw grabs the rubber and pulls it forward into the heated barrel.

b) Plasticizing and Conveying

This softened rubber is now ready to be pushed through the die. As the screw rotates:

- The rubber is compressed, mixed, and heated

- Heat comes from barrel heaters and friction

- The rubber becomes soft and plastic-like (but not yet cured)

4. Die Design and Extrusion Through the Die

a) Die Design

Die design is critical. Poor design can cause defects like fishtailing, swell, distortion, or uneven dimensions. Die design depends on:

- Shape of the profile (solid or hollow)

- Dimensions and tolerances

- Flow behaviour of the rubber compound

b) Extruding the Profile

There is often a slight die swell, meaning the extruded profile becomes slightly larger than the die opening. This is accounted for in die design and process settings. Once the rubber compound reaches the die:

b) Plasticizing and Conveying

This softened rubber is now ready to be pushed through the die. As the screw rotates:

- It is forced through the die opening under pressure

- The rubber takes the cross-section shape of the die

- The extrudate that comes out is soft and not yet cured

5. Cooling, Handling, and Pre-Cure Support

Right after extrusion, the rubber profile is still soft and can deform easily.

a) Cooling or Support Systems

The aim is to carry the extrudate smoothly to the curing section without stretching or twisting. To maintain the shape:

- The profile may be cooled with air or water

- Sometimes it is guided through conveyor belts, caterpillar pullers, or support trays

- For hollow sections, air pressure inside the profile may be used to prevent collapse

6. Curing / Vulcanization of the Extruded Rubber

Curing (vulcanization) is the step where the rubber gains its final properties like elasticity, strength, and compression set resistance.

a) Curing Methods

The extruded profile passes through the curing system at a controlled temperature and speed, ensuring proper vulcanization time. Common curing methods in rubber extrusion include:

- Continuous hot air oven curing

- Salt bath curing

- Microwave curing followed by hot air

- Steam autoclave (for some specific cases)

b) Vulcanization Reaction

Correct curing is crucial. Under-cure or over-cure can negatively affect performance. During curing:

- Cross-links form between rubber molecules

- The material changes from a plastic state to an elastic, permanent shape

- Properties like hardness, tensile strength, and compression strength are developed

7. Post-Curing, Cooling, and Dimensional Stabilization

After curing, the rubber profile is usually hot and may still be slightly unstable. This stabilizes the dimensions and makes handling easier.

a) Cooling

The profile is cooled:

- Using water baths or

- Air cooling systems

b) Straightening and Tension Control

This gives a neat, uniform extruded product. Sometimes, the profile is carefully pulled and aligned to avoid:

- Bending

- Distortion

- Length variation

8. Cutting, Splicing, and Finishing Operations

Once the extrusion is cooled:

a) Cutting to Length

The continuous extruded profile is:

- Cut into fixed lengths using cut-off knives or saws

- Or wound into coils or rolls for flexible profiles like cords and tubes

b) Splicing and Jointing

For making endless gaskets or seals, the cut ends may be:

- Spliced and joined using adhesives

- Or hot vulcanized to create a strong joint

c) Surface Finishing

These steps make the product ready for packaging and shipment. Additional finishing may include:

- Trimming excess material or flash

- Surface coating or powdering (for slip and handling)

- Printing or marking with batch or part numbers

9.Quality Control and Inspection

At every stage of the rubber extrusion manufacturing process, quality control is important. Consistent monitoring ensures that extruded rubber profiles meet customer drawings, tolerances, and performance requirements. Common checks include:

- Dimensional inspection – width, thickness, inner/outer diameter

- Visual inspection – surface defects, cracks, voids, fishtailing marks

- Hardness testing – Shore A hardness

- Mechanical testing – tensile strength, elongation

- Specific property tests – compression set, aging, oil resistance, heat resistance Cutting, Splicing, and Finishing Operations

Why Choose Custom Rubber Extrusion?

At Custom Rubber Extrusion, we are driven by core values that guide our business and define our commitment to our clients.

Expertise and Experience - With years of experience in the Extrusions industries, we have the expertise to deliver custom-designed solutions that meet the most demanding requirements.

High-Quality Products - Our ExtrusionsExtrusions are made from high-quality materials, ensuring durability, clarity, and long-lasting performance.

Custom Solutions - We specialize in providing tailored Extrusions solutions that meet the unique needs of our clients.

Exceptional Customer Service - We provide end-to-end support, from initial consultation to post-delivery assistance, ensuring our clients are delighted with the results.

In summary, the manufacturing process of rubber extrusion starts with selecting and compounding the right rubber, followed by feeding into an extruder, shaping through a die, curing, cooling, cutting, and final inspection. Careful control at every step ensures that the final extruded rubber product meets performance requirements and provides long-term reliability in its application.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.