Medical & Healthcare

Leak Prevention

Durable & Flexible

Customizable Design

Temperature Tolerance

Corrosion Protection

- Home

- Medical Rubber Extruded Parts

Precision Rubber Extrusion Solutions for Medical and Laboratory Equipment

Medical rubber extruded parts are carefully made parts that are essential for accuracy, dependability, and cleanliness in delicate settings. These bellows play important roles, like preventing fragile tools, preventing contamination, and providing regulated motion or flexibility in machinery. This makes them a reliable choice for medical equipment like anesthesia machines, ventilators, diagnostic tools, and lab automation systems.

At Custom Rubber Extrusion, we focus on manufacturing superior bellows that fulfill the demanding performance needs of medical and lab devices. Our bellows are made with high-quality rubber and silicone, so they can withstand harsh chemicals, temperature changes, and sterilization. We design each extrusion to be durable, easy to clean, and safe for various medical applications.

With our experience and expertise in this field, we can provide bellows that not only meet strict medical requirements but are also durable, flexible, and long-lasting. These bellows help control and move air smoothly, all while preventing contamination. Our bellows are accurately made to perform under pressure, even after repeated sterilization.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Custom Rubber Extrusion Solutions with Proven Expertise

1395 projects & 690 happy clients.

At Custom Rubber Extrusion, our focus is on designing and manufacturing Extrusion products specifically designed to meet the individual needs of each of our customers. We have a decade of experience in the industry, during which we've successfully delivered over 1395 projects for a wide range of industries, and are proud to have served more than 690 happy clients.

We customised every Extrusion to meet your exact requirements, guaranteeing durability, dependability, a perfect fit, and top-notch performance. Whether it's for the automotive, oil and gas, construction, chemical, or general industrial sectors, our products are made with precision to handle the toughest conditions.

5+

Countries

11+

Industries Served

1395+

Projects Completed

690+

Clients

RUBBER BELLOWS INDUSTRY

Industry Served

Why Choose Us

Custom Solutions for Medical Grade Rubber Profiles

We make medical-grade rubber profiles to perfectly match the specific needs of your medical devices. We customise our bellows with extreme accuracy and care to help your equipment last longer. The key benefits of these bellows are:

- Custom Design: Every bellows is uniquely shaped and sized to match the intricate designs of medical assemblies and their specific movement needs.

- Material Versatility: We provide a range of material options, like silicone and medical-grade rubber, all of which meet all relevant medical regulations.

- Enhanced Flexibility: These bellows are made to handle movement and pressure changes while still maintaining their excellent sealing performance.

- Regulatory Compliance: This product fully meets the requirements of ISO and FDA standards for manufacturing medical devices.

- Long Service Life: They are durable enough to handle compression and the sterilization process over time, without degradation or material breakdown

Why are Rubber Seals a Preferred Choice?

Healthcare sealing rubber seals are a crucial component in laboratory settings where cleanliness and resistance to chemicals are crucial. We use premium silicone materials that can endure numerous sterilization cycles and cleaning procedures, all while maintaining their flexibility and structural integrity. The following are the reasons that make rubber seals are better choice:

- High Temperature Resistance: They can handle a range of temperatures, from very cold (-60°C) to quite hot (+230°C), without breaking down.

- Superior Flexibility: These bellows maintain their flexibility and create a tight seal, even when they're constantly being compressed or stretched.

- Excellent Chemical Resistance: They stand up well to harsh chemicals like acids, solvents, and strong lab cleaners, which helps them last longer even in tough conditions.

- Non-Toxic Material: They are quite safe and don't react with other substances, making them a great choice for labs where safety is important.

- Smooth Surface Finish: Their non-stick and smooth surface doesn't let contaminants stick around, making it super easy to clean or sterilize.

Why Choose Us?

As a pharmaceutical rubber channel components maker, we focus on making flexible bellows that are designed to help control movement, dampen vibrations, and protect sensitive parts in medical and lab equipment. We aim to create designs that are both very durable and provide excellent sealing, allowing for complex movements while keeping out contaminants such as dust, liquids, and bacteria. Here are the reasons why our customer chooses us:

- Precision Engineering: Each bellows is carefully made to match the exact measurements required for a seamless fit to medical devices.

- Material Expertise: We rely on top-quality rubber and silicone to guarantee that our bellows are reliable and durable.

- Wide Range of Products: Whether you need standard bellows or intricate designs for medical devices, we've got you covered.

- Custom Solutions: We design bellows according to your specific needs, taking into account your unique requirements and operating environment.

- Quality Assurance: Every bellows is thoroughly tested to ensure it can tolerate extreme temperatures and pressure to function effectively.

- On-time Delivery: Our consistent production and timely delivery schedules ensure all orders arrive when promised.

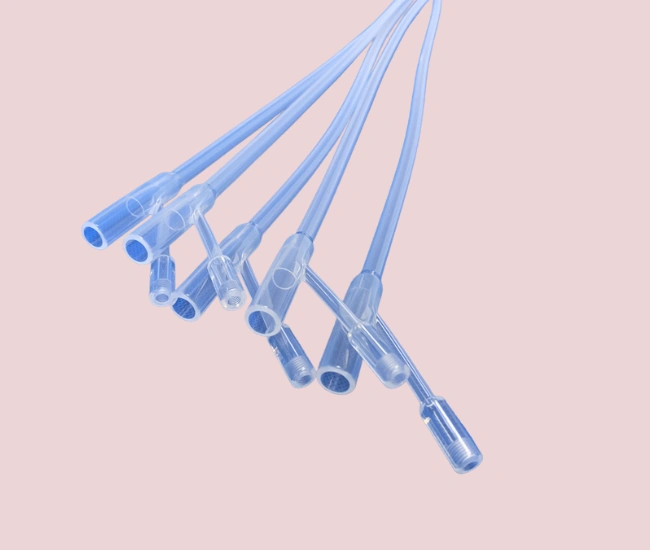

Importance of Medical Sterilizable Rubber Gaskets

Medical sterilizable rubber gaskets are made to handle movement, temperature fluctuation, and vibrations from heavy-duty equipment, pipes, and air ducts. The special six-sided shape gives them extra strength and flexibility to perform well even when there's a lot of pressure or force. These bellows keep connected and moving parts safe from extreme mechanical stress, helping to prevent leaks and breakdowns.

We specialize in making durable and resilient hexagonal expansion bellows that can resist high temperatures and harmful chemicals. Industries such as construction, automotive, HVAC systems, and oil & gas benefit from these bellows because they're so strong and versatile. Their flexible design lets them adjust to shifts in length or position that might occur due to temperature changes or heavy loads.

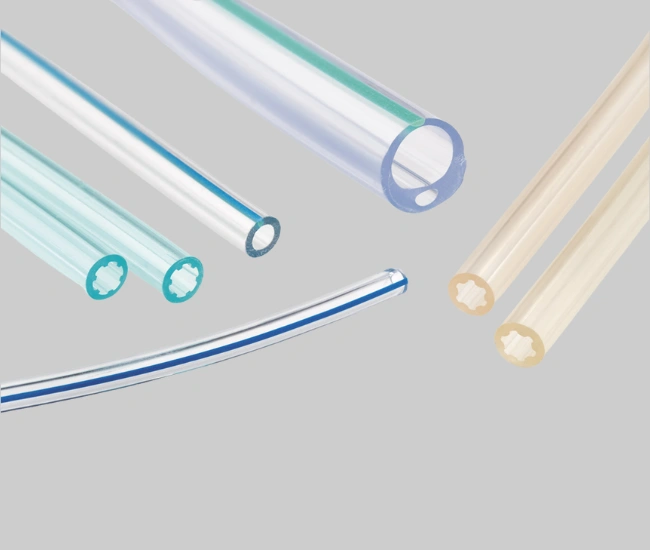

Manufacturing Process of Medical Silicone Tubing & Hoses

Our medical silicone tubing & hoses are designed to excel in demanding environments where protection and accurate sealing are essential. We guarantee they adhere to strict laboratory safety and performance standards, ensuring consistent, clean, and smooth operation. Our quality-focused manufacturing process of silicone tubing includes:

- Material Selection: We choose the appropriate silicone medical-grade based on the application.

- Mold Design: We create a very precise mold to give the hoses the desired shape every time.

- Molding Methods: We use precision molding methods to make the bellows through either compression or injection molding under high pressure.

- Curing and Cooling: The silicone is cured and then carefully heated and cooled to give it the right strength and sterilization resistance.

- Trimming and Finishing: Any extra material is trimmed away, and the edges are smoothed to create a clean and smooth finish.

- Quality Testing: Every tubing is carefully tested to ensure the bellows doesn't leak and effectively protects against contaminants.

Contact Us for Your Needs

Medical & Laboratory Gakstes or EPDM medical-compliant extrusions are crucial and completely safe for medical and laboratory devices. They're made to support the important equipment that drives progress in the medical and laboratory industry. We are proud to serve the medical and laboratory industries worldwide with versatile, contaminant-resistant, and high-performing rubber tubing. Contact us today to discuss the need for reliable medical bellows, and we can help you. We make our gaskets with non-toxic materials that meet the strictest requirements for performance and safety. We provide a diverse selection of hoses designed to deliver dependable protection and help your medical and laboratory equipment last longer.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.