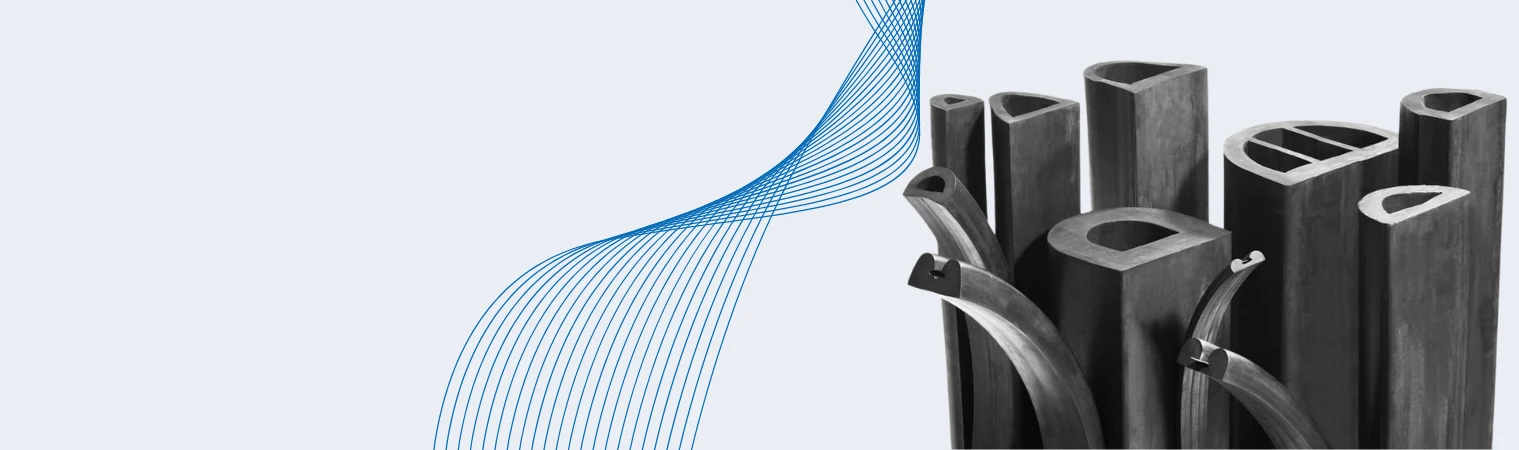

Rubber Profiles

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

- Home

- Silicone Rubber Profile

Silicone Rubber Profiles for Versatile Applications

Silicone rubber profiles are a very common and mostly used product in many different industries. Due to silicone's stable nature and resistance to environmental damage, it's appropriate for both indoor and outdoor applications. Their flexibility, durability, and ability to resist high temperatures make them perfect for automotive, medical, food processing, construction, and electrical industries.

At Custom Rubber Extrusion, we're experts in making high-quality silicone rubber shapes that perform reliably even in challenging conditions. Our custom-made profiles are strong enough to endure severe temperatures, corrosive substances, and UV exposure, all while staying flexible and strong. We custom-made profiles in various sizes, dimensions, and hardness levels to suit your specific industrial application for sealing, insulation, and protection.

We use advanced manufacturing methods to make these profiles with precise sizes, consistent quality, and smooth surface finishes. From creating tight seals for doors and windows and protecting wires to ensuring leak-proof connections, our profiles provide dependable performance and durability across a variety of situations.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Rubber Profiles

Our Products

What Are Silicone Extrusion Profiles?

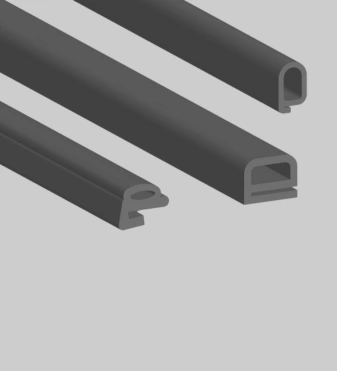

Silicone extrusion profiles are essentially long pieces of silicone rubber created by pushing the material through a die to make unique cross-sectional shapes. These shapes are tubes, cords, seals, and gaskets. Because of the extrusion process, the resulting shapes are consistently accurate in size, which makes it ideal for large-scale production. These profiles are popular for applications demanding flexibility, reliability, and long-lasting protection from environmental damage. Because they're made using the extrusion process, they're easy to customize specific profiles for sealing or cushioning applications across various industries.

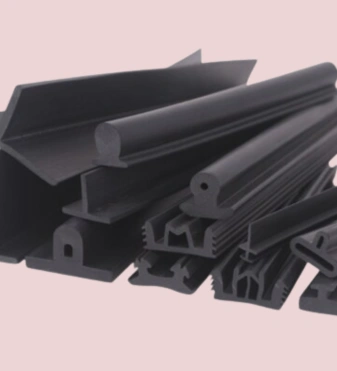

Types of Extruded Silicone Profiles We Offer

We provide different types of extruded silicone profiles to fulfill the various needs of different applications. We use modern manufacturing equipment to guarantee uniformity and accuracy in all our silicone profiles. The types include:

- Solid Silicone Profiles: These are durable and strong, which is perfect for applications that demand strength and stability.

- Sponge Silicone Profiles: These are lightweight and can be compressed easily, which makes them great for sealing uneven spots.

- Co-extruded Silicone Profiles: This combines different levels of silicone hardness for particular functions.

- Transparent Silicone Profiles: Perfect for applications that demand visual inspection

- High-Temperature Silicone Profiles: Designed for high-temperature environments that require constant exposure to heat.

Customization Options for Silicone Rubber Profiles

We collaborate closely with our customers to design and manufacture a range of custom silicone rubber profiles that ideally suit their precise project specifications. Our customisation options include:

- Shapes: We provide a variety of shapes, including U-channels, T-sections, D-shapes, hollow tubes, solid cords, and even complex custom forms.

- Colors: We have several color options available, including transparent, white, black, red, and any custom colors for specific preferences.

- Hardness: The hardness can be customised, ranging from very soft (20 Shore A) to quite firm (80 Shore A), depending on application requirements.

- Grades: Silicone comes in different grades, such as industrial, medical, or food-grade compounds.

- Adhesive Backing: We provide optional pressure-sensitive adhesive backing for simple installation.

Countries

Industries Served

Projects

Clients

Manufacturing Process of Silicone Rubber Extrusion Profiles

Silicone rubber extrusions are a process where raw silicone material is transformed into shaped parts using a careful and monitored technique. This process generally includes these key steps:

- Material Preparation: We start by choosing top-quality silicone rubber compounds that match the specific qualities we need.

- Extrusion: That silicone compound goes into an extruder, where it is pushed through a die to make a precise profile shape.

- Curing: After that, the extruded material is vulcanized (heat-cured) to boost its strength and stability.

- Design Support: We provide design assistance, make CAD models, and build prototypes to ensure accurate fit and function.

- Cutting and Finishing: The profiles are cut down to the exact lengths and then verified for a smooth surface finish and dimensional accuracy.

- Quality Testing: Every batch of silicone rubber extrusion is tested to check its hardness, tensile strength, flexibility, and temperature resistance.

Features and Benefits of Silicone Extruded Profiles

Silicone stands out because it's strong, flexible, and doesn't react easily with chemicals. That's why silicone extruded profiles are often chosen for a variety of applications:

- Temperature Resistance: These materials perform effectively in temperatures ranging from -60°C up to +230°C, while maintaining their flexibility or shape.

- Weather and UV Resistance: Silicone profiles endure direct sunlight, ozone exposure, and severe weather conditions, which makes them perfect for outdoor applications.

- Non-Toxic and Food-Grade: Silicone is best best-suited material that meets food and medical standards where hygiene and safety are top priorities.

- Flexible and Resilient: Silicone is also superbly resistant to compression, which means it maintains its shape even after being compressed many times.

- Chemical Resistance: It doesn't easily break down when exposed to different oils, acids, and chemicals, making it a great choice for harsh industrial settings.

- Electrical Insulation: Silicone is a fantastic non-conductive insulator, so it's perfect for electrical and electronic components.

Why Choose Us?

As a leading silicone extrusion profiles manufacturer, we ensure that each silicone rubber extrusion is manufactured with strict quality standards. When you choose us, you're working with a team that prioritizes quality, accuracy, and customer satisfaction. We focus on manufacturing top-quality silicone rubber shapes designed to fit your exact industrial requirements.

With our advanced tooling capabilities, material expertise, and advanced extrusion processes, we guarantee that every single item we make meets demanding size and performance goals. We partner with our customers to manufacture customised silicone rubber profiles that are strong, flexible, and dependable. From prototype development to large-scale production, we provide comprehensive service, competitive prices, and fast delivery.

Contact Us for Your Needs

Silicone extrusion profiles are really important in industries that need high-performance and strength to withstand environmental damage. We use our materials expertise and top-notch molding equipment to make dependable silicone profiles for different applications. We make silicone rubber extrusions for every type of industry, from automotive seals to food-grade gaskets. Get in touch with us today to discuss your needs for silicone extrusion profiles. If you need regular silicone profiles or custom extruded profiles, we ensure precision, quality, and consistency in every project. Our profiles are designed to provide superior performance even in the most harsh conditions.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.