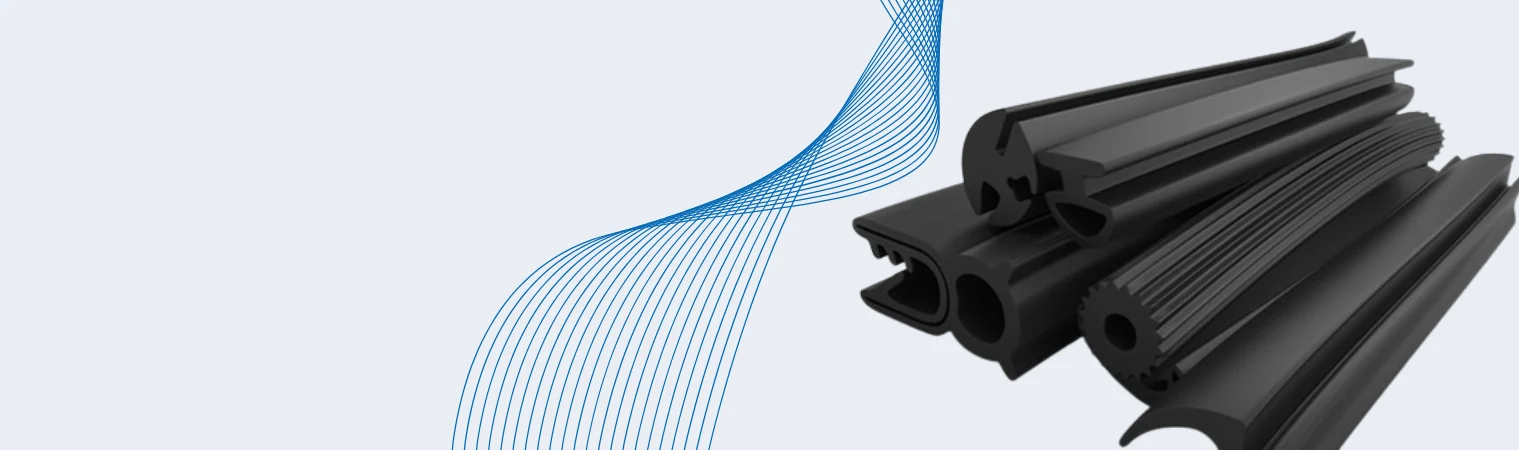

Rubber Gaskets

Weatherproof

UV Resistant

Long Durability

Premium Quality

High Performance

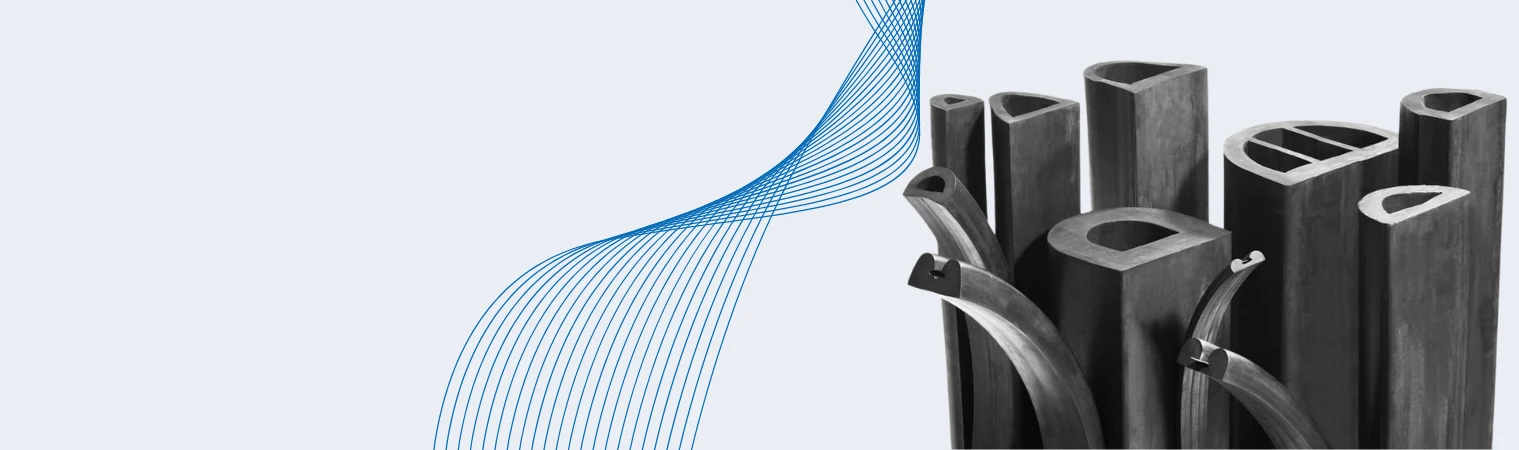

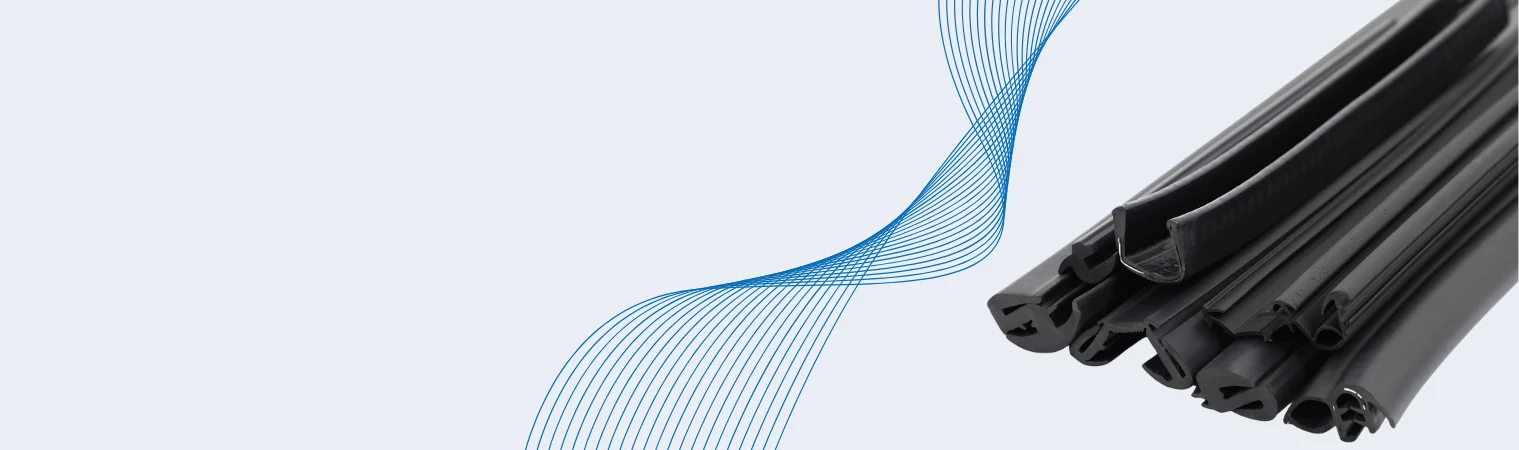

Rubber Profiles

Custom Designs

Precision Fit

Smooth Edges

Longer service life

Accurate Dimensions

Rubber Seals

Heat Resistant

Long Durability

Protective Sealing

High Compression

Customizable sizes

Rubber Channel

High Elasticity

Reliable Sealing

Custom Sizes

Weather Resistant

Superior Performance

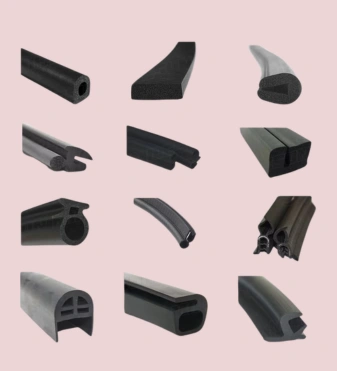

Rubber Extrusions

Perfect Fit

Anti-Vibration

UV Resistant

High Precision

Easy Installation

EPDM Extrusion

High Durability

Smooth Finish

Superior Quality

Custom Shapes

Versatile Use

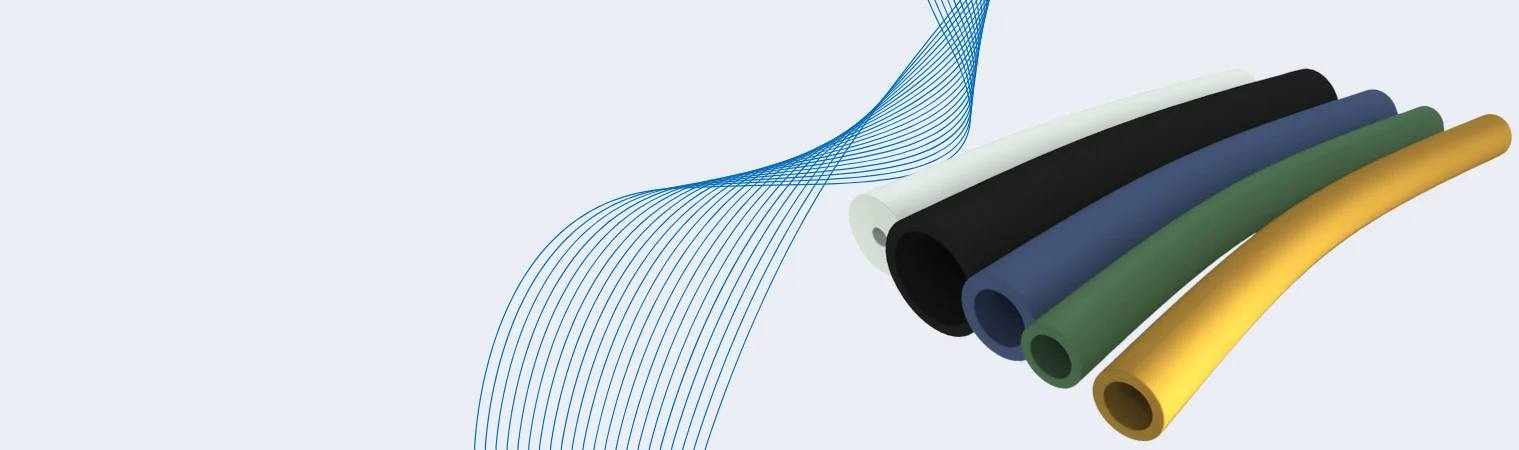

Tubing & Hoses

Smooth Flow

High resilience

Custom Lengths

Leak Prevention

Chemical resistant

- Home

- Co Extruded Rubber Profiles

Custom Co-Extruded Rubber Profiles for Automotive and Industrial Applications

Co-extrusion is an advanced manufacturing process in which two or more rubber materials are extruded together to form a single profile with varying hardness levels or colors, all within a single continuous section. For example, a profile with a soft rubber portion for sealing and a harder rubber section for structural support. This dual-material design enhances the flexibility, strength, and sealing performance of the product, making it suitable for complex applications.

At Custom Rubber Extrusion, we make custom co-extruded rubber profiles that deliver precision, consistency, and functionality across demanding industrial environments. By integrating different rubber compounds like EPDM, silicone, and TPE, we achieve exceptional resistance to temperature, weather, and chemicals.

Whether you require co-extruded rubber profiles for sealing, vibration control, or insulation, we deliver custom solutions that meet your exact specifications. Our in-house tooling, design, and quality control ensure both reliability and durability. With years of experience as a trusted custom co-extruded rubber profiles manufacturer, we provide high-quality rubber components for specific applications.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

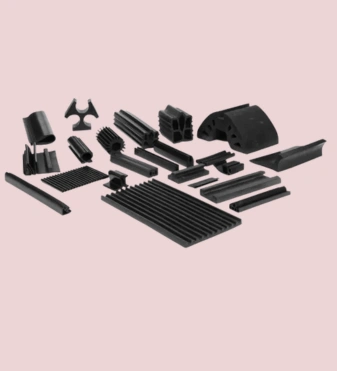

Other Extruded Products

Our Products

Why Industries Prefer Co-Extruded Seals & Gaskets

Industrial co-extruded rubber seals and gaskets are widely used to provide consistent sealing, reduce noise and vibration, and help protect equipment from dust, moisture, and contaminants. These seals and gaskets are designed to perform in harsh environments such as:

- High or low temperature conditions

- Exposure to oils, fuels, chemicals, or UV

- Continuous movement, compression, or vibration

- Machine enclosure doors and panels

- HVAC units and industrial cabinets

- Electrical control panels and switchgear

- Industrial ovens, freezers, and processing lines

Typical Industrial Applications

Key Benefits of High-Performance Rubber Components

We manufacture high-performance co-extruded rubber components that serve various functional needs such as insulation, cushioning, and vibration control. The co-extrusion process ensures that the performance of each component is optimized for the application’s requirements. The key benefits include:

- Enhanced Sealing Performance: They provide tight, consistent sealing against dust, moisture, air, and fluids, reducing leaks and improving overall system efficiency.

- Superior Durability: Designed to withstand wear, abrasion, and repeated movement, these components offer a longer service life even in demanding environments.

- Vibration and Noise Reduction: By absorbing shocks and vibrations, these components help protect equipment and reduce noise levels, improving comfort and performance.

- Design Flexibility & Customization: Available in custom shapes, hardness levels, and materials, they can be tailored to specific applications, ensuring a perfect fit and optimal results.

Co-Extruded Rubber Profiles for Automotive & Industrial Applications

The automotive and industrial sectors rely heavily on co-extruded rubber profiles due to their unique ability to combine flexibility, durability, and weather resistance in a single product. In both sectors, co-extruded rubber profiles provide superior sealing performance, reduced noise, and longer service life. They also simplify installation, reducing assembly time and maintenance costs.

Automotive Applications

- Door and trunk seals

- Window channels

- Roof rail seals

- Glazing seals

- Noise and vibration dampers

Industrial Applications:

- Equipment enclosure seals

- Cabinet gaskets

- Conveyor belt edges

- Electrical housings

- Machinery vibration dampers

Countries

Industries Served

Projects

Clients

Your Trusted Custom Rubber Extruded Profiles Supplier

As a trusted custom rubber extruded profiles supplier, we provide complete design-to-delivery support for all types of co-extruded profiles. We also provide post-extrusion services like cutting, joining, bonding, and custom packaging. Our Process Includes:

- Concept & Design: We begin with understanding the functional and environmental needs of the product.

- Material Selection: Choosing suitable compounds based on temperature range, chemical exposure, and flexibility.

- Tooling & Prototyping: Custom die creation ensures the exact shape and tolerance requirements are met.

- Extrusion & Testing: Using advanced extrusion lines for continuous and accurate profile production.

- Quality Control: Dimensional checks, hardness testing, and visual inspection to maintain consistency.

Why Choose Us?

If you select us as your co-extruded rubber provider, you will be working with a team that has a deep knowledge of the materials, the uses, and the performance. We are fully equipped to produce any co-extruded rubber parts that are engineered to be the exact fit for your needs. We provide a full range of services from compound selection to profile design and tooling in your automotive or industrial applications. We are committed to quality consistency, perfection of measurements, and efficient sealing performance.

We are able to provide products that are dependable and capable of good performance as a result of our proficiency in rubber extrusion and co-extrusion. Our commitment to quality and accuracy has been the main reason that we have become a reliable and well-known company in the rubber extrusion industry. Choosing the proper material combination is the main factor that the co-extruded profile will work efficiently in the particular atmospheric conditions. Our internal testing labs are always ready to make sure that every product is up to industry standards and is what the clients expect.

Contact Us for Your Needs

Are you in need of a trustworthy producer of Custom Co-Extruded Rubber Profiles? Don't hesitate to get in touch with Custom Rubber Extrusion now. Our team is eager to assist you in the development of co-extruded rubber seals, gaskets, and profiles, which are in line with your specifications and performance requirements. If it's just a few units of a prototype that you require or large quantities of production, contact us today. We offer you solutions that are of great quality, long-lasting, and affordable, and that are personalized to your requirements.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.