Tubing & Hoses

Flexible & Durable

Leak-proof design

Chemical Resistance

Custom shapes & sizes

Easy installation

- Home

- Fuel & Oil Resistant Hoses

Reliable Fuel & Oil Resistant Hoses for Industrial Applications

Fuel & Oil Resistant Hoses are vital components that are used in different types of industries for safely handling petroleum-based products like lubricants, oils, diesel, and other fuels. These hoses are designed to endure challenging environments as they can withstand elevated temperatures, pressure variations, and exposure to oils or fuels that would damage standard materials.

At Custom Rubber Extrusion, we recognize that problems with fuel or oil hoses can lead to leaks, fire risks, equipment malfunctions, and expensive delays. That is why we attentively design and manufacture premium-quality fuel and oil-resistant hoses that deliver high performance in harsh environments. Our hoses reliably transfer fuel and oil, preventing leaks and or contamination. This makes them a great choice for automotive, industrial, and marine applications.

We use quality rubber material for excellent durability, flexibility and the ability to withstand damage from oil, cracking, and corrosion, ensuring a long service life. Whether you require standard hoses or custom solutions for specific applications, we provide comprehensive services to effectively and affordably address your individual needs.

Ready to See your Idea into Reality

We have served 264+ Clients so far…Discuss your Requirements with Our Experts.

Tubing & Hoses

Our Products

Fuel and Oil Resistant Hose Manufacturers You Can Trust

As one of the trusted fuel and oil-resistant hose manufacturers, we know the importance of precision, safety, and reliability in industrial environments. We're committed to ensuring that every hose is of high quality. That's why we use the best materials, advanced manufacturing processes, and careful testing. Here are the reasons why our customers choose us:

- Industry Experience: We have a decade of experience working with many industries, like automotive, construction, marine, and power generation.

- Premium Materials: We carefully choose the material compound for making durable fuel and oil-resistant hoses.

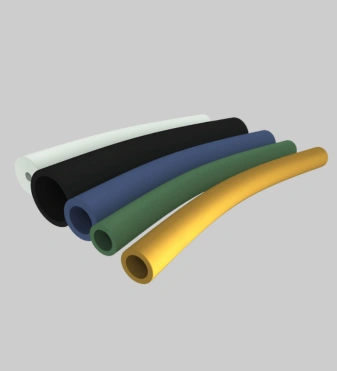

- Custom Design: We also customize these hoses in various shapes and sizes to suit the exact design of your application requirements.

- Heavy-Duty Capabilities: Our hoses are specially designed to handle high-pressure variations in harsh environmental conditions.

- Strict Quality Control: Each hose is tested for quality, dimensions, performance, and durability.

- On-Time: We provide flexible production capabilities and dependable on-time delivery to help you maintain your project timelines.

Important Factors to Keep in Mind for Industrial Fuel Hose

Among industrial fuel hose manufacturing companies, we stand out for our deep industrial expertise and customer-centric approach. We use top-notch manufacturing techniques like extrusion, along with careful quality checks, to make hoses that are tough enough to meet the demands of industrial applications. This guarantees that our hoses provide safe and efficient performance, even when they're constantly exposed to oils, fuels, and hydraulic fluids. Important factors we pay attention to:

- Properly formulated to resist deterioration from fuels and oils.

- Adequate strength is needed to withstand the necessary operating pressures.

- Should remain flexible for easy and fast installation.

- Resist wear and tear and prevent swelling, cracking, or leaking over time

- Withstand extreme temperatures without losing flexibility or performance.

Countries

Industries Served

Projects

Clients

Manufacturing Process of Heavy-duty Fuel-Resistant Hose

As one of the reliable heavy-duty fuel-resistant hose makers, we make top-notch hoses for multiple industrial applications. Our fuel-resistant hoses are manufactured through a controlled process that combines various rubber materials and finishing methods. This manufacturing process includes:

- Material Selection: We select the appropriate oil and fuel-resistant rubber compounds (such as NBR) to suit the specific needs of the application.

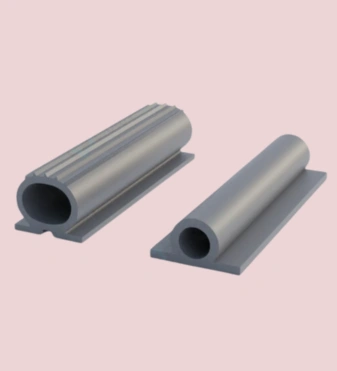

- Inner Tube Extrusion: The rubber is shaped into a smooth inner tube that will directly transfer the fuel and oil.

- Reinforcement: To strengthen the hoses to withstand pressure, they are wrapped with reinforcing layers, such as fabric, special fibers, or metal wire.

- Outer Cover Extrusion: A strong rubber cover is applied over the reinforcement layer to protect from chemicals and external damage

- Curing/Vulcanization: The complete hose assembly is cured to boost its flexibility, mechanical strength, and overall durability.

- Cutting and Finishing: The hoses are cut to the required lengths and fitted with the appropriate end connectors.

- Quality Testing: Once finished, each hose undergoes testing for quality, dimensional accuracy to ensure all performance criteria are met.

Custom Solutions for Fuel-Resistant Hoses

Custom fuel-resistant hose made just for your application needs. We prioritize performance, safety, and lasting quality, so your systems run smoothly with minimum downtime. We work closely with you to understand your requirements and deliver hoses that truly guarantee dependable performance and long-lasting quality. Our custom solutions include:

- Perfect Fit: We design each hose to match your exact fuel type, pressure, temperature range, and size requirements.

- Higher Service Life: We select the right rubber compound and strong reinforcements that help prevent leakage, thereby ensuring a high service life.

- Compatibility with Fuels & Oils: We select materials that are compatible with fuel, oil, and harsh chemicals.

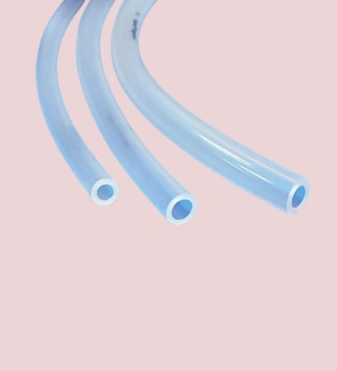

- Flexible Design: We provide hoses in custom diameters, lengths, and configurations to fit your equipment perfectly.

Why Choose Us?

As one of the reliable oil-resistant rubber hose manufacturers, we manufacture hoses that deliver consistent performance even under prolonged oil exposure. We use rubber compounds such as Nitrile (NBR), Neoprene, and Viton, which provide great resistance to fuel, oil, and other chemicals. This helps stop the hose from swelling, cracking, and hardening when constantly exposed to oil or chemicals. This means the hose retains both its flexibility and durability for an extended period.

Every single hose we design is made with meticulous attention to detail to ensure it meets international quality standards, delivering reliable performance and safety you can trust. We manufacture our hoses with reinforced layers to maintain their shape and structural integrity even in the most demanding conditions. Additionally, each hose undergoes a thorough inspection process, including rigorous burst pressure testing, flexibility testing, and material integrity testing to ensure it meets the standard.

Contact Us for Your Needs

Fuel & Oil Resistant Hoses are a vital component across numerous industries due to their exceptional flexibility, temperature tolerance, and chemical stability. Whether you require high-purity tubing for medical use or durable hoses for industrial machinery, selecting the right manufacturer is crucial. Contact us today to discuss your requirements in detail, and we will help you for sure. We provide complete solutions for fuel & oil-resistant hoses. With precision extrusion, advanced materials, and expert engineering, we deliver tubing that ensures performance, safety, and longevity.

Ready to See your Idea For Custom Rubber Below

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.