Fast Delivery And Low MOQ With Money Back Guarantee...

In the manufacture of plastic parts, both smart design and quality are always the cornerstones. Modern manufacturing requires precision and efficiency, which for injection molding is achieved through advanced design, mold flow analysis, and prototyping.

Design of injection molding services help transform product ideas into final products by supporting the refinement and modification of product concepts for efficient production.

The part design is made to meet the manufacturing capacities of the molding process and, therefore, manufacturers can eliminate unnecessary production issues and reduce costs.

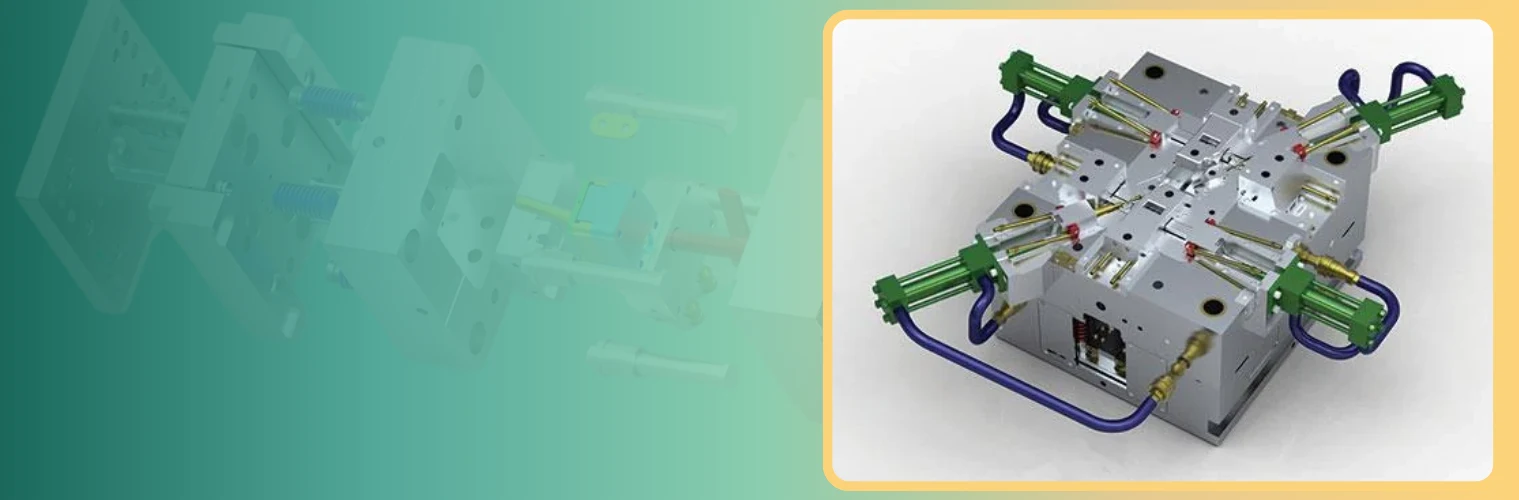

Custom Mold Design and Tool Building help ensure long-term performance, consistency, and repeatability of precision parts over thousands of manufacturing cycles.

Strengths and Advantages

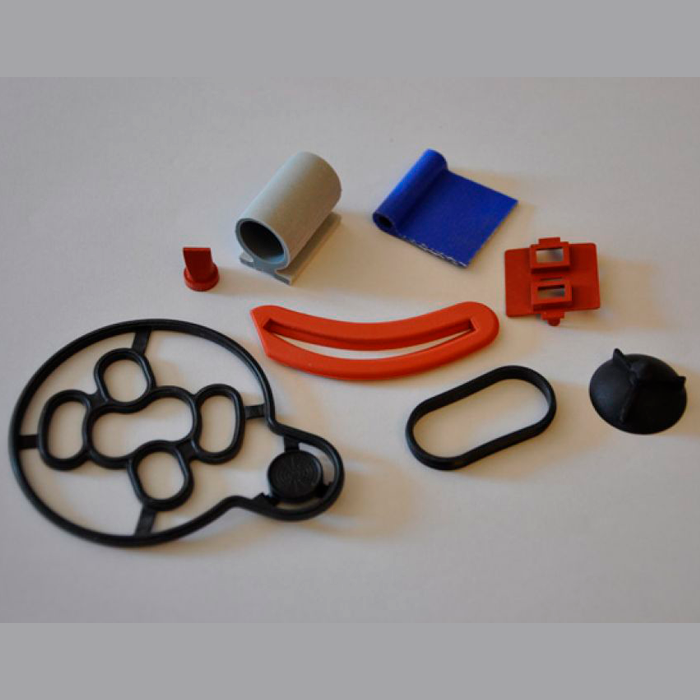

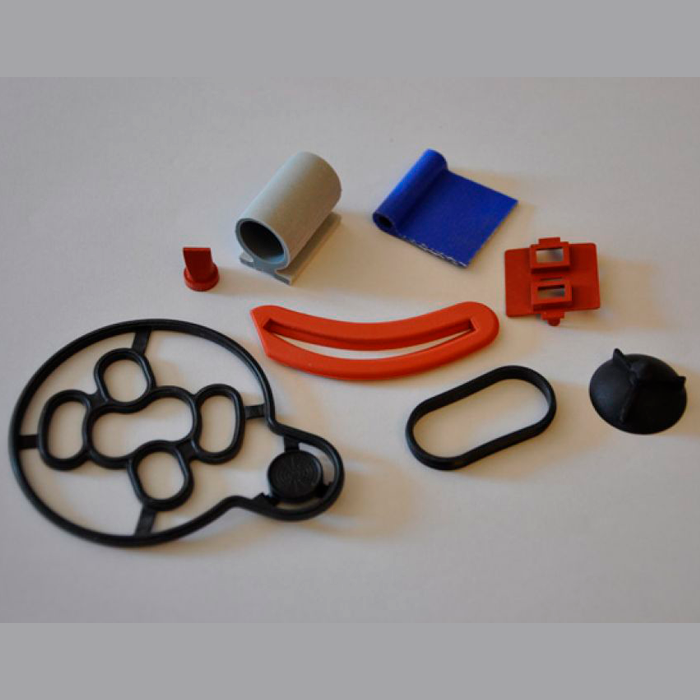

Rapid Injection Molding for Prototypes provides low cost parts with fast tooling.

Advantages of Quick Molded Prototypes

Thermoplastic engineering part design focuses on optimizing the part structure, material, and performance to get maximum strength, precision, and functionality.

Key Aspects of Thermoplastic Design:

Mold flow analysis for injection molding is used to anticipate any problems that may arise before milling begins on the tool.

Benefits of Mold Flow Simulation:

We believe in providing reliable, innovative, and cost-effective plastic injection molding solutions. Your trust allows us to deliver products that are precise, durable, and reliable.