Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

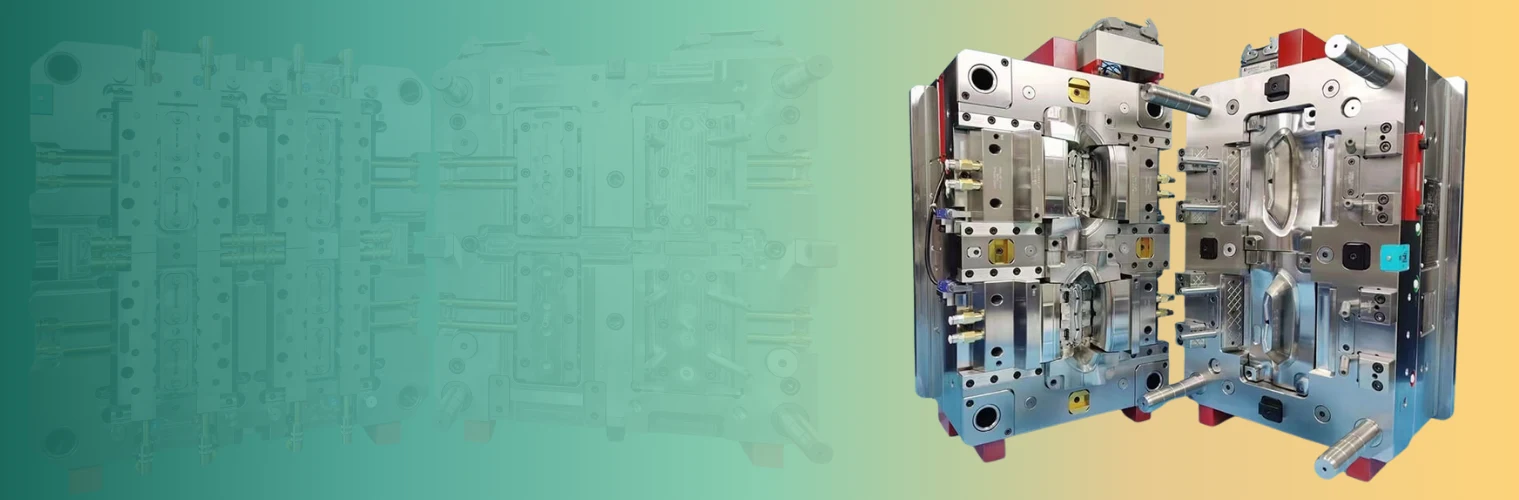

One of the primary driving forces of our business is the plastic injection tooling service. Our potential for manufacturing and high-quality services makes the delivery of crucial plastic components the distinctive pillars of our dealings with customers. From outstanding injection molds to creating excellent tools, we offer a warranty on our deliveries to substantiate the claim. If you have a demand for plastic injection mold tooling , you can approach us to fulfill the requirements.

Tooling involves a multitude of skills and that is why we dedicate a team of qualified engineers to serve the industries. We have facilities for tool construction related to injection molds to meet the requirements of customers. Here is what we do in injection molding tooling services.

Out years is an experience in injection, molding, and tooling relates to an experience of several years and we have engineers separate tooling personnel, and engineers to complete the job.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

We provide injection moulding tooling services according to the specifications of customers. With a manufacturing period ranging from a fortnight to about two months, our timed delivery has made the customers trust our potential irrespective of the complexity of the mold structure, the part size, accuracy, and the life of the mold. We can create molds for automobiles, office and household applications, and other commodities. The team of engineers keeps the clients posted about the progress of work every week before the final delivery.

Select our plastic tooling manufacturing services to ensure accuracy, dependability, and superior quality with each mold.

Whether you need a small batch of product prototypes, the prototyping molds we use are optimized for low-volume requirements. At the same time, we ensure that molds maintain their characteristics even when the cycle time is faster. We use outstanding quality materials and the base of molds is highly robust. We stand behind our techniques and offer a warranty for the life of the product.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

As a plastic tooling manufacturing Company, we understand how a superior mold is essential to reduce the cost of production. If you are keen to take plastic tooling to the next level, associate with us. The following are the reasons why customers choose us.

The precision of manufacturing tools is a skill we have attained for several years. Although the equipment and technology we use today have come a long way from the previous days, we put the same attention to small or large tooling projects. For all the molding and tooling requirements, call us today.

One common manufacturing technique for producing plastic components is injection molding. However, have you ever thought about how these complicated shapes are formed? Using injection mold tooling is the solution.

Specialized molds used in injection molding are referred to as injection mold tooling. These molds, which are usually made of aluminum or steel, serve as a negative imprint of the intended plastic component. High-pressure molten plastic is pumped into the mold cavity, solidifying and cooling to take on the shape of the mold.

For products with advanced features, mold tooling may become fairly complex, even if other molds may be rather basic. To make it easier to create undercuts, threads, and other design aspects, these molds may also have slides, cores, and lifters.

As a business owner, you understand the importance of having an Plastic injection mold machine for the job. When it comes to plastic injection molding, choosing the right machine can make all the difference in the quality and efficiency of your production process.

At Plastic Injection Molding, we are committed to helping you make informed decisions for your business. Here are some tips for choosing the right machine for plastic injection molding.

There are three main types of plastic injection molding machines such as:

#1. Hydraulic injection molding machines: These machines use hydraulic pressure to inject molten plastic into a mold. They are known for their precision and reliability and are commonly used for high-precision parts with tight tolerances.

Hydraulic machines can handle high injection speeds, making them suitable for high-volume production. However, they can also be more expensive than other types of machines due to their complex design and high maintenance costs.

#2. Electric injection molding machines: These machines use electric motors to power the injection process. They are quieter and more energy-efficient than hydraulic machines and can be more precise in controlling injection speed and pressure.

Electric machines are ideal for small to medium-sized parts that require high precision, but they may not be suitable for high-volume production due to their slower injection speeds.

#3. Hybrid injection molding machines: These machines combine the best of both hydraulic and electric machines, using electric motors for the injection process and hydraulic power for other functions. Hybrid machines are known for their energy efficiency and speed, making them suitable for high-volume production with high precision.

They are also quieter and more precise than hydraulic machines and can save energy costs in the long run. However, they may have a higher upfront cost compared to hydraulic machines.

Considerable factors when choosing an injection molding machine

At Our Plastic Injection Molding, we offer a wide range of plastic molding machines to meet the needs of various industries. Our team of experts can guide you through the selection process and help you choose the right machine for your business.

Get Ready to change your Product Vision into Realty...