Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

Rapid prototyping and engineering is a process that allows engineers and designers to quickly create a physical prototype of a product. It involves the use of computer-aided design (CAD) software and 3D printing technology to produce a physical model of a part or product. The purpose of rapid prototyping is to allow for quick and easy testing and evaluation of product designs before committing to mass production. By creating a physical prototype, designers can test the functionality, fit, and form of a product, and make necessary modifications before investing in expensive tooling and production. Rapid prototyping has become an essential tool for engineers and designers in a variety of industries, including aerospace, automotive, medical, and consumer products.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

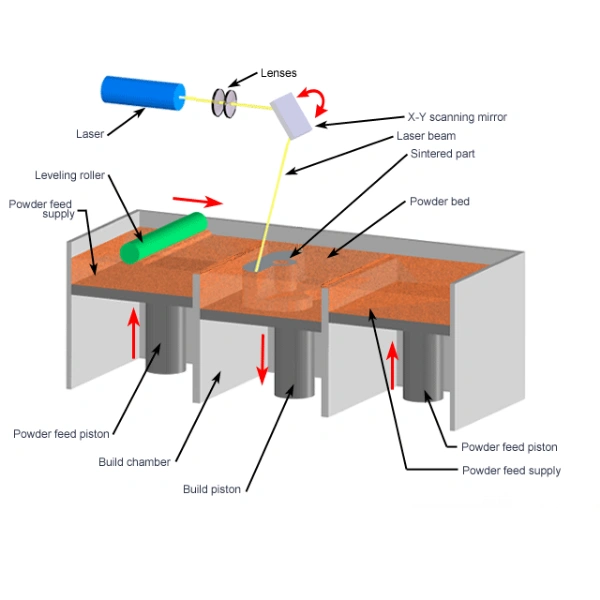

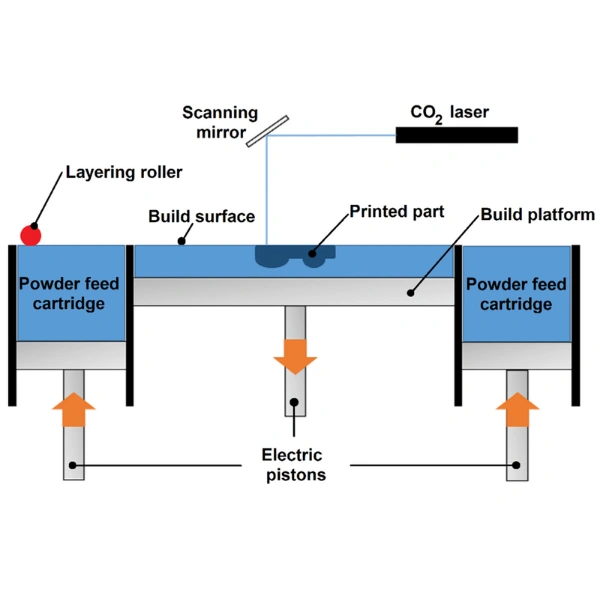

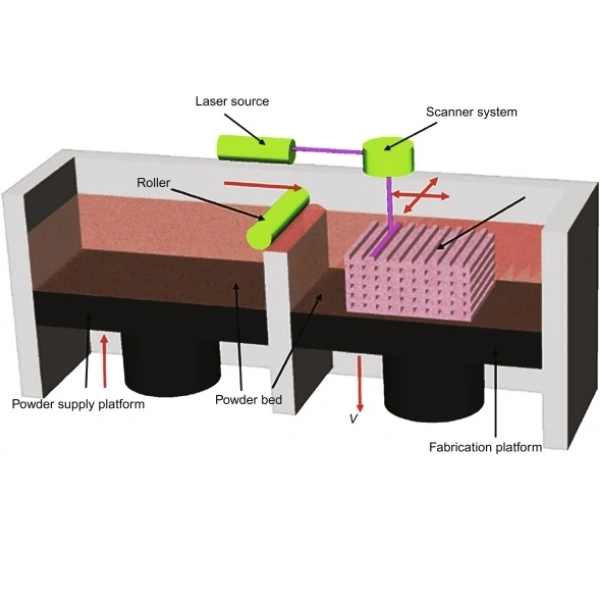

We excel in rapid prototyping and engineering and a leading company offering selective laser sintering technology to the customers for creating rapid prototypes. For additive manufacturing of 3D parts with complex shapes, you can trust the services. The rapid prototype stereolithography services we offer is used for creating patterns for urethane casting, concept models, presentation models, and complicated parts with varied geometries. Here is why we are the chosen service provider for several companies.

The SLA rapid prototyping uses ultraviolet laser to draw in the surface of liquid thermoset resin, leading to the creation of thin layers until the formation of final parts. If you are keen to achieve excellent features, eager to choose from a wide range of materials, and need high-quality surface finishes, using SLA is the best choice.

The rapid prototyping and tooling services we offer are credible and enhances the product development process. Right from the stage of computer-aided design to the physical part, the entire process moves at a very fast speed. Our team of project managers can help you understand the basics of prototyping services and allow you to decide whether SLS or SLA is the right option to choose. We also specialize in cheap rapid prototyping and provide the cost estimate according to the demands of the clients instead of charging them exorbitantly.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

For choosing an ideal data transmission format, the STL rapid prototyping is one of the ideal options to choose. To create the STL files, the key considerations to undertake are smoothness and faceting, thickness of the wall, saving the tabbed parts, and checking the missing surfaces. We are here to handle all the requirements of customers suitably and deliver the best in manufacturing production parts.

If you are keen to avail our prototyping and tooling services in quick turnaround times get in touch with us for fabricating multiple parts of a design during the stage of product development.

Get Ready to change your Product Vision into Realty...