Fast Delivery And Low MOQ With Money Back Guarantee...

The electronics industry heavily relies on injection molding to make durable, precise, and lightweight parts that are essential for everyday gadgets.

Injection molded electronic housings ensure that the protective housings, as well as the performance and long-term reliability of the tiny precision components, remain consistent.

Millions of electronic products are protected by injection-molded housings on the outside. These housings provide durability, precise fit, and a clean finish while safeguarding internal components from damage, dust, and moisture.

Molded connectors and switches are highly precision molded components, essential for stable electrical performance.These components are manufactured with extreme precision as even the slightest variation can affect the operation and reliability of the devices.

They are used in automotive electronics, computers, power supplies, industrial equipment, and control systems. Their fire resistance and high heat resistance properties make them ideal for these electrial applications.

These components have to withstand continuous wear and tear, exposure to the surrounding environment, and mechanical loads with the addition of continuous electric functioning.

Electronic devices need casings that are lightweight yet strong to improve user experience without adding extra weight. Lightweight plastic casings for gadgets are durable, impact-resistant, easy to grip, and visually appealing.

The manufacturers develop ultra-thin-wall casings for smartwatches, handheld devices, portable scanners, wireless gadgets, and small controllers.

These casings can include extra features like fingerprint resistance, UV protection, anti-slip finishes, or soft-touch surfaces. More sophisticated molding techniques are used to make sure that all the ports, buttons, holes of speakers, and mounting points are perfectly aligned so that the assembly of devices can be easily done.

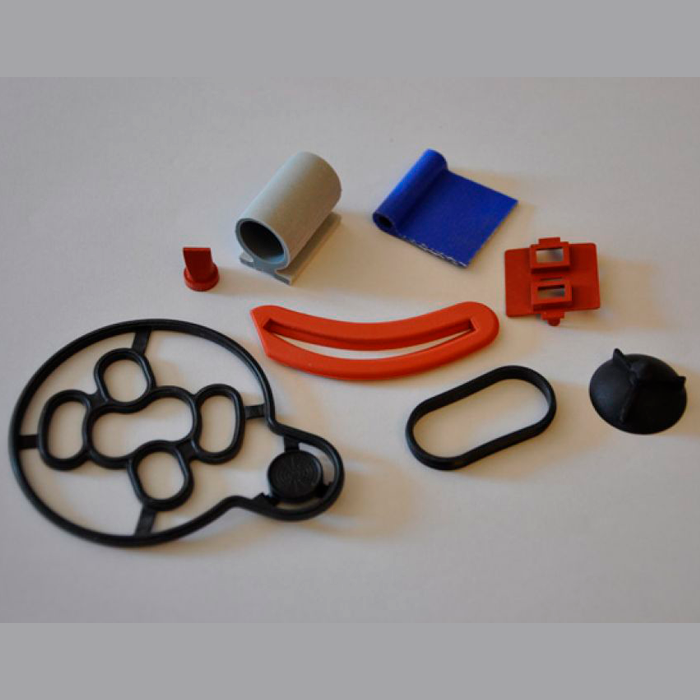

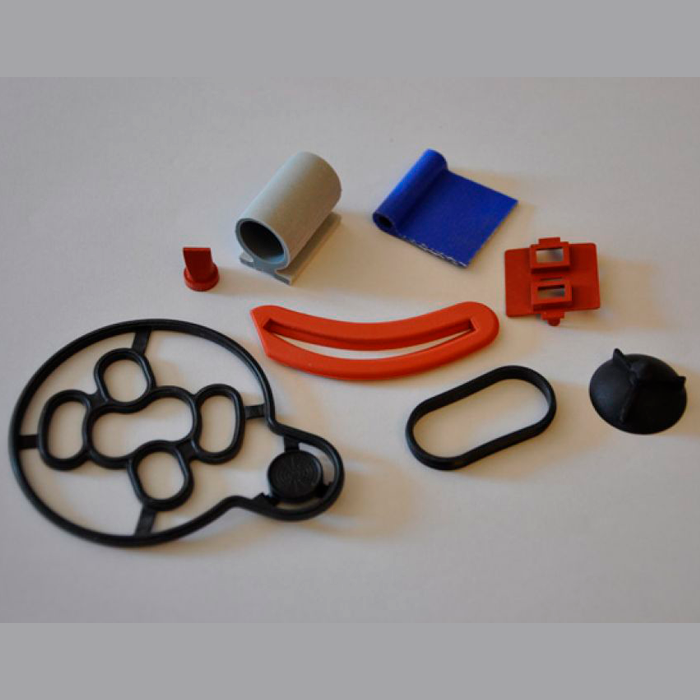

Micro-component parts that are used internally in complex electronics require high-precision electronic component molding. These are miniature housings, clips, sensor brackets and part switches.

Using micro-injection molding techniques, manufacturers are able to create millions of identical products with micron-level accuracy.

Application include:

Precise molding means that every part fits exactly into the device, and this assures an outstanding performance regardless of the long period of use.

ABS and PC are some of the most common materials used in the electronics industry because they are strong, heat resistant, and have a good surface finish.

ABS/PC plastic molding for electronics combines the strengths of both materials, making parts that are strong and visually appealing.

Applications include:

They are also durable against drops, temperature changes, and regular handling, making them an ideal choice for electronic applications worldwide.

We believe in providing reliable, innovative, and cost-effective plastic injection molding solutions. Your trust allows us to deliver products that are precise, durable, and reliable.

Mobile & laptop plastic housing molding provide high accuracy, toughness, and a smooth finish to electronic devices. These things define the look, functionality, and durability of modern digital devices.

Materials like PC-ABS, reinforced PC, and TPU blends are commonly used to make mobile phones, tablets, laptops strong and consistent.

Using thin-wall injection molding, manufacturers can create lightweight yet very strong and precise housings. These housings can also be made through overmolding, multi-shot molding, or insert molding to add metal reinforcement or rubber grips.