Fast Delivery And Low MOQ With Money Back Guarantee...

Thin wall plastic packaging molding is designed for a fast manufacturing process. It is used to manufacture lightweight, durable, and efficient packaging products.

It is also widely used for the food, medical, cosmetic, and consumer goods industries. This advanced molding technology supports large-scale production, reduces material usage, and ensures high product safety and performance.

A breakdown of the key categories that influence current packaging innovation is detailed below. These categories highlight the trends, materials, and technologies shaping modern packaging solutions.

Plastic closures & lids molding are vital in the process of sealing, protecting and preserving products packed in. Closures that are made by injection molding are of high quality in terms of precision and functional excellence.

Features & Benefits:

Beverages, dairy products, pharmaceuticals, cosmetics and industrial products require plastic closures.

Food grade injection molded packaging is always the surest way of ensuring maximum hygiene safety and contamination prevention. These are products that are in accordance with FDA, EU and international food-contact standards.

Advantages:

This packaging facilitates branding, convenience and long term food safety in challenging market conditions.

We believe in providing reliable, innovative, and cost-effective plastic injection molding solutions. Your trust allows us to deliver products that are precise, durable, and reliable.

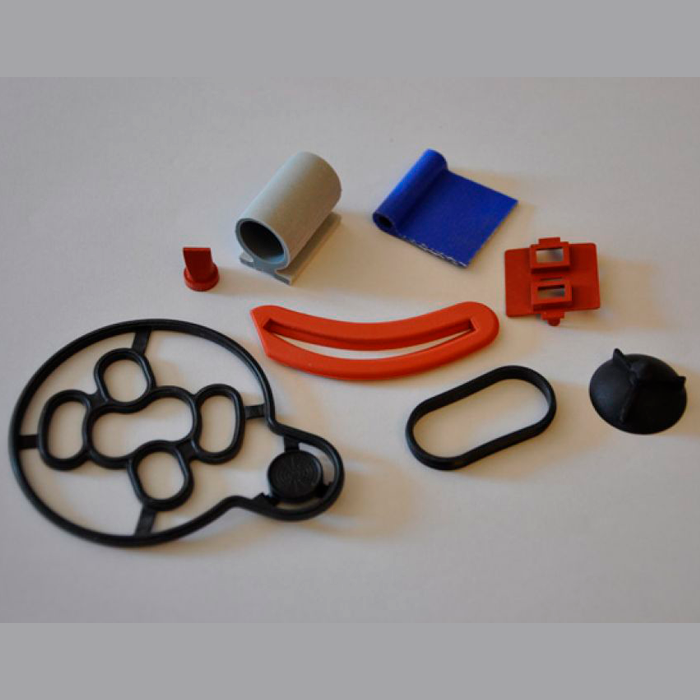

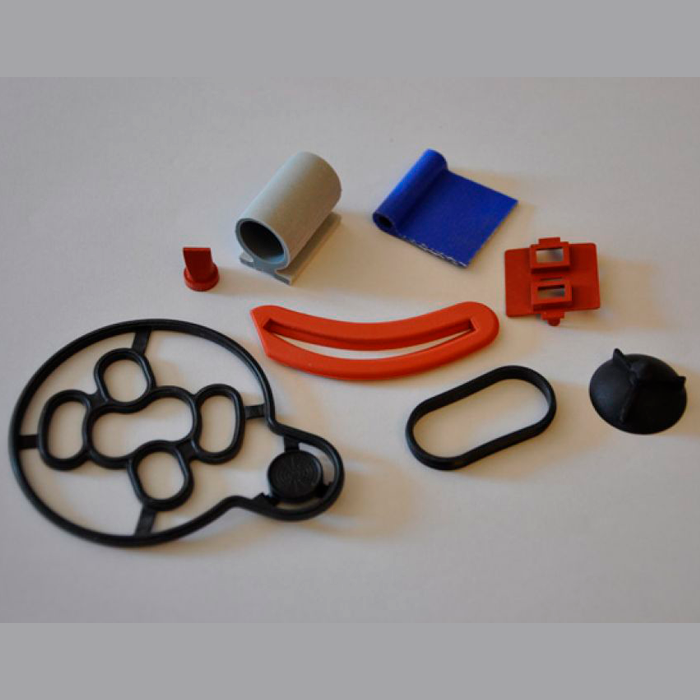

Lightweight consumer packaging plastic parts help in reducing shipping costs, improve sustainability, and offer convenience to end users. This is achieved through thin-wall molding without compromising strength.

Key Features:

Light packaging is essential to the brands that are oriented to sustainability and the design of the products that are user-friendly.