Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

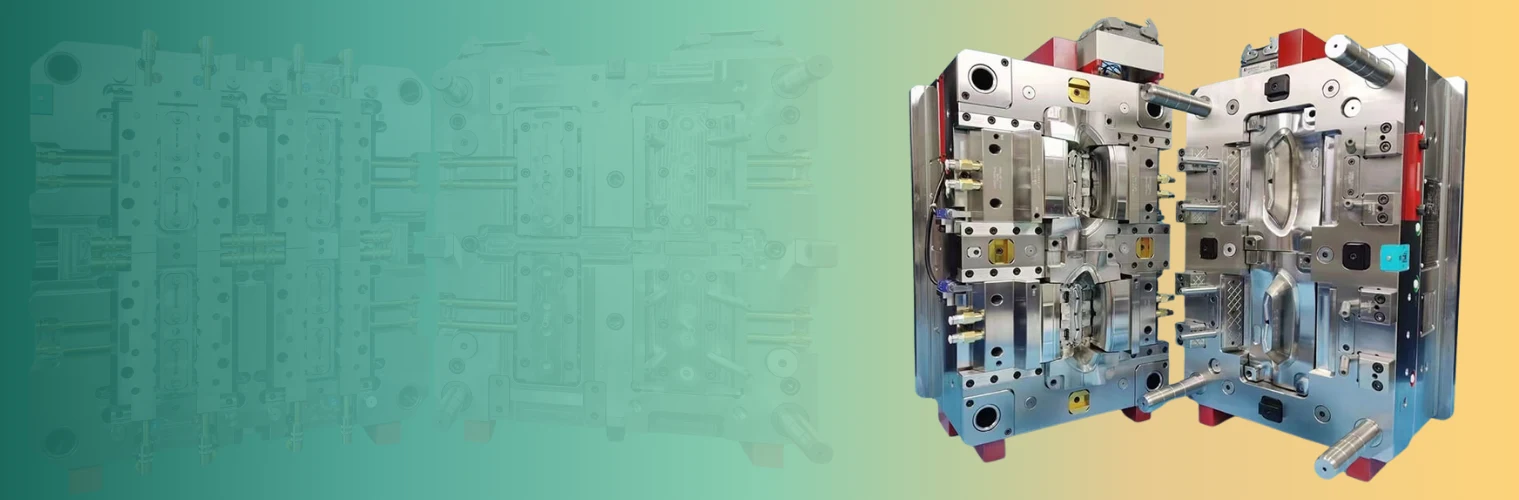

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

Injection molding is one of the preferred methods for manufacturing plastic parts. However, a good mold is essential to get a quality part. Therefore, you need to associate with an experienced service provider for injection mould tool design . We are one of the leading service providers with knowledge of minimizing the huge expenses involved in designing tools and manufacturing for producing excellent parts. As an industry leader in injection mold tool design we have proved our efficacy time and again.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

Our team of engineers optimizes the design of the mold and the chosen materials for injection moulding tool design and ensures that manufacturing of parts goes on smoothly. Once the client finalizes the concept design of the project, we get into the act with full force to produce the prototypes within a short period of interval.

We use 3D printing or other tooling of production that can cater to low or high-volume production. Therefore, the customers can evaluate the appearance and function of the design of new product and enhance the speed of market availability. Here is a snapshot of our capabilities in injection moulding tool design .

We provide professional assistance in plastic injection mould tool design service according to the industrial standards. Our company has a team of design professionals and mold tooling engineers who can design injection molds from the basic single cavity prototypes to multiple options. All we request you is submit the quotes and get the rates of production handly.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

Get Ready to change your Product Vision into Realty...