Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

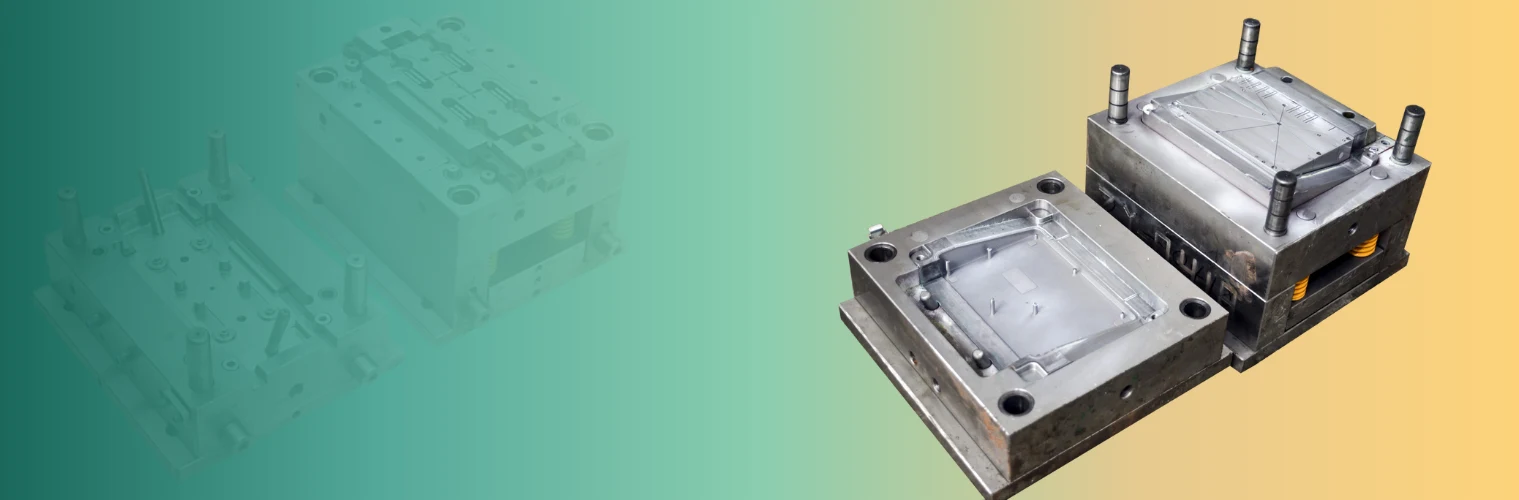

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

Irrespective of the size of your business, we are an excellent plastic mold maker offering a wide range of services to the customers. If you have a concept design for plastic mold, our expert CNC machinists and mold makers are ready to serve you exceptionally well. We have attained recognition for making plastic molds and satisfy the requirements of customers. Whether it is mold design or selection of material, we stand by the customers in offering the best services within their budget. Here is a snapshot of our commitment.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

We are experts capable of meeting the demands of the customers. Our experience in plastic mold making make us cater to the customers with ease irrespective of the size of the project we handle. Plastic mold making is fast gaining the reputation of one of the preferred methods of manufacturing precise plastic parts. We leverage on the concept of manufacturing plastic molded parts and components to reduce the cost of labor and minimize waste. Note the following points before choosing our services.

Our facility is a storehouse of various sizes of molding machines for manufacturing high-quality products. The core value of the company lies in offering plastic mold making services at affordable rates. We continue investing in new opportunities and orient our capabilities to meet the requirement of customers. Call us today for obtaining high-quality plastic molded parts and components.

Ever wonder how your favorite toys or things around the house are made? Well, there are these awesome folks called plastic mould makers who make it happen! We're like the architects of cool shapes, crafting special molds that turn melted plastic into the stuff we use. Whether it's a toy or a handy gadget, our makers use their skills to design molds that make everything just right. It's like magic – we think about how the gooey plastic flows and cools to make sure things come out perfect. So, next time you see something made of plastic, remember the cool creators behind the scenes!

While PVC mold manufacturing offers numerous advantages, there are also some challenges associated with the process. Here are some of the key challenges that manufacturers may face when producing PVC molds:

Choosing the right fiberglass mold maker can have a significant impact on the success of your project. When evaluating potential partners, there are several factors to consider. First, look for a manufacturer with experience in your industry or application. They should also have a track record of delivering high-quality products on time and within budget. Consider their manufacturing capabilities, including their equipment and technology. Communication is also critical, so look for a manufacturer who is responsive and transparent throughout the process. Finally, consider their pricing and any additional services they may offer, such as design and engineering support. By evaluating these factors, you can choose a reliable and capable fiberglass mold manufacturer for your project.

In conclusion, the choice between fiberglass molding and PVC mold making will depend on the specific requirements of your project. Factors such as production volume, part complexity, and material properties will all play a role in determining which method is right for your needs. Consulting with a trusted manufacturing partner can help you make an informed decision and ensure the success of your project.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

The Importance of Quality Control in Urethane Moulding Companies

Urethane molds are a great choice for many products, but they do have their limitations. The most common problems associated with urethane molding are shrinkage and warping. If you want to avoid these issues, you should consider using thermoset or compound molds instead!

Urethane Moulding

Thermoset moulding companies is a low-cost process, which makes it ideal for creating prototypes and small runs of products. It’s also fast and flexible, making it an excellent choice if you need to produce something quickly and then move on to another project.

Urethane molds are durable, resilient, easy to repair and strong enough for most applications. They can be used in many different materials such as wood or plastic (depending on the material you want your mould made from).

Thermoset Moulding

Thermoset moulding is a process that uses heat and pressure to cure a plastic resin into a solid. It is a one-time use process that can be used for high-volume production, though it tends to cost more than urethane moulder, which means you may need to factor in extra expenses if you’re looking at large orders.

In addition to its durability, thermoset resin also offers better detail than thermoset moulder since it has no extrusion lines or areas where air bubbles form when heated during processing – making your product look more professional and realistic.

Compound Moulding

If you’re looking for the best of both worlds, compound moulding is your best option. This process combines the benefits of thermoset and urethane moulding into one product. Compound molds can be made from either ABS or polypropylene (PP), depending on your needs and budget, but they typically take longer to set than a standard urethane part due to their higher viscosity.

Compound molds are also ideal for high-volume production because they’re easy to use and require little maintenance once they’ve been created.

Urethane moulding companies are especially important because they have a higher risk of defects. The quality control process for urethane moulds is more rigorous than other types of moulds, so it’s important to ensure that your company has the right equipment and personnel to do the job right.

Thermoset molds are less likely to be damaged by temperature changes or pressure changes during production, which means they’re less likely to experience defects like warping or shrinkage. This can make them an attractive choice for companies that need high-quality products on short deadlines (like pharmaceutical companies).

Get Ready to change your Product Vision into Realty...