Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

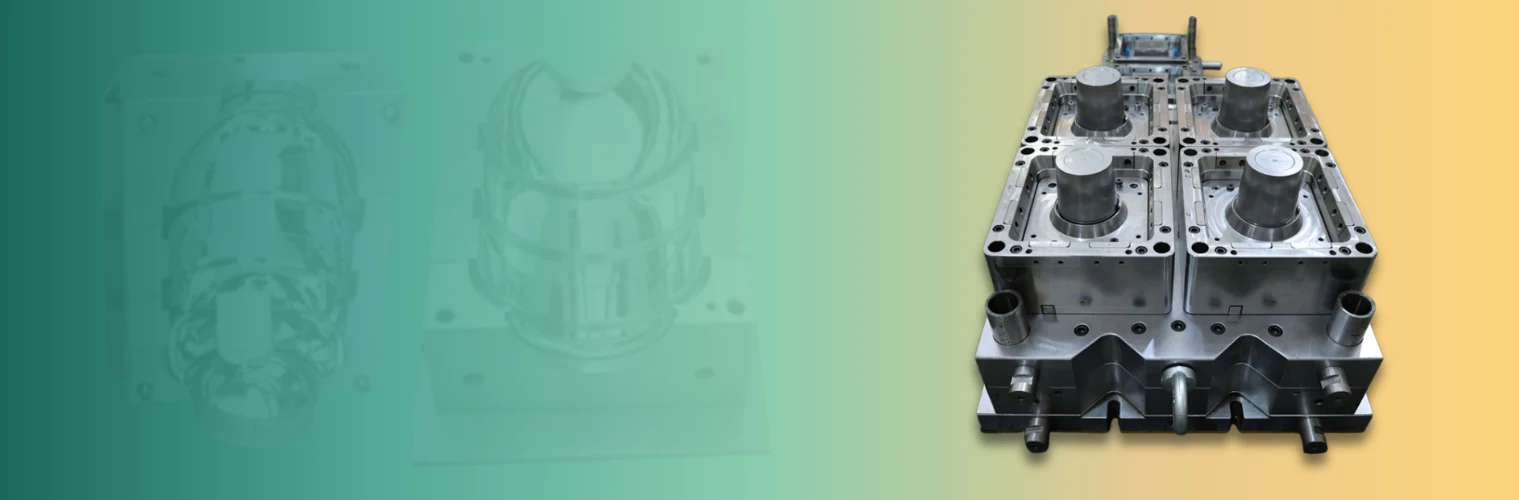

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

In layman’s term, rotomoulding is widely used for parts which are in need of higher quality finishes, higher stability and uniformed wall thicknesses. Some of the features will be spin weld attachment and inserts, which can be added into the rotomould directly. After that, you can use the foam to create stiffness and thermal insulation. Learning about the process of this molding is always the best motive to consider in here.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

It is mandatory for you to learn more about the process of rotomould before you can start planning to use it. This form of molding will always involve one heated hollow mold, which is then filled up with short weight or charge of material.

As part of the rotational molding, the cap mould will involve heated base hollow mold. It is completely filled up with shot weight or charge weight of material.

With passing time, there have been improvements in the process control and developments of the extrusion moulding with that plastic powders. It will result in the increasing use for sure.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

In case this is your very first time dealing with polystyrene moulding , then it is vital that you get in line with the professionals. They are more than happy to offer you with impressive results all the way through.

Without wasting any time further, it is time for you to select us for some of your impeccable home appliance mould options to cover. We are more than happy to be your assistance in offering premium quality molds, which are hard to find from anywhere else. Just give us a call or join us for the best molding experience.

Get Ready to change your Product Vision into Realty...