Get Ready to change your Product Vision into Realty...

Fast Delivery And Low MOQ With Money Back Guarantee...

We deliver consistent, high-quality plastic components through advanced tooling, controlled processes, and strict quality inspection standards.

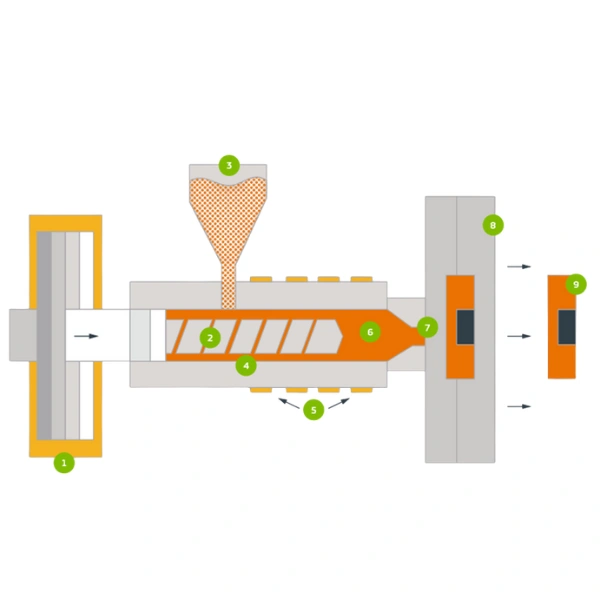

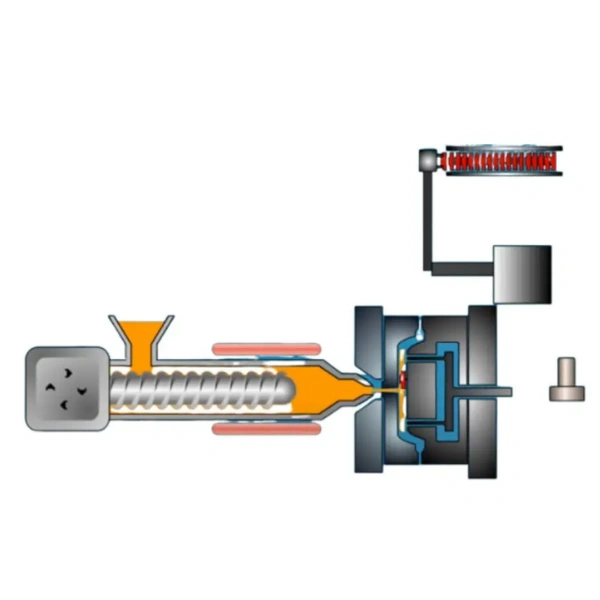

We design and manufacture custom injection-molded parts meeting specific design, material, and functional requirements across industries.

Modern injection molding machines ensure repeatable quality, tight tolerances, and efficient high-volume production cycles.

Diam elitr kasd sed at elitr sed ipsum justo dolor sed clita amet diamFrom prototypes to high-volume manufacturing, we support scalable production while maintaining quality and cost efficiency.

The fused deposition modeling technology allows people to use high-quality engineered-grade thermoplastics that are suitable for harsh environments and various other demanding applications. As one of the leading prototyping companies, we provide a comprehensive service from design to production. With a good collection of FDM 3D printers, we can build prototypes in quick turnaround time.

We are dedicated to providing precision, efficiency, and innovative plastic solutions for your manufacturing needs.

We design and produce custom plastic components that meet exact specifications and performance requirements.

Read MoreOur team supports product design and prototyping to ensure a seamless transition from concept to production.

Read MoreWe provide scalable solutions for high-volume production while maintaining strict quality standards.

Read MoreWe work with a wide range of thermoplastics to ensure durability, strength, and application-specific properties.

Read MoreEvery part undergoes rigorous quality checks to ensure consistency, precision, and reliability.

Read MoreWe create precision molds that maximize efficiency and minimize waste.

Read More

The 3D printing technologies we use are competent for rapid prototyping at the initial stage and for additive manufacturing of production parts and components. To add to your favor, we provide all round consultancy services and provide the necessary support and advice based on the choice of material optimization, and selection of process. Why choose us for deposition modeling ? The following points will highlight.

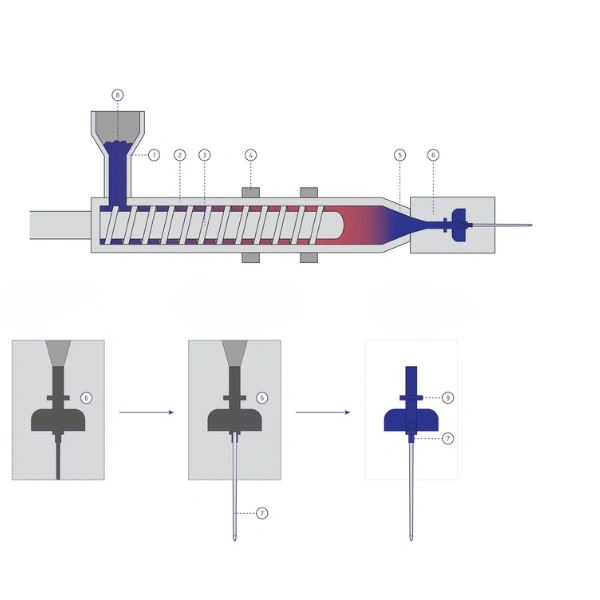

Our insert molding service is a highly effective and strong method of manufacturing wherein a metal or plastic insert is places into the mold for creating the final part. The technique is viable and highly useful for critical medical device and automotive applications. Why should you choose our insert molding service? The following points will highlight.

With several years of experience in insertion molding service, we are one of the most recognized manufacturers and suppliers of insert molded products and components. The insertion molding service we offer are suitable for medical, electronics, automotive, and aerospace industries. We supply some of the most critical components to the clients while sticking to the highest level of quality.

We value your time and ideas. Expect quick replies, transparent processes, and expert advice for your project requirements.

Get Ready to change your Product Vision into Realty...