Fast Delivery And Low MOQ With Money Back Guarantee...

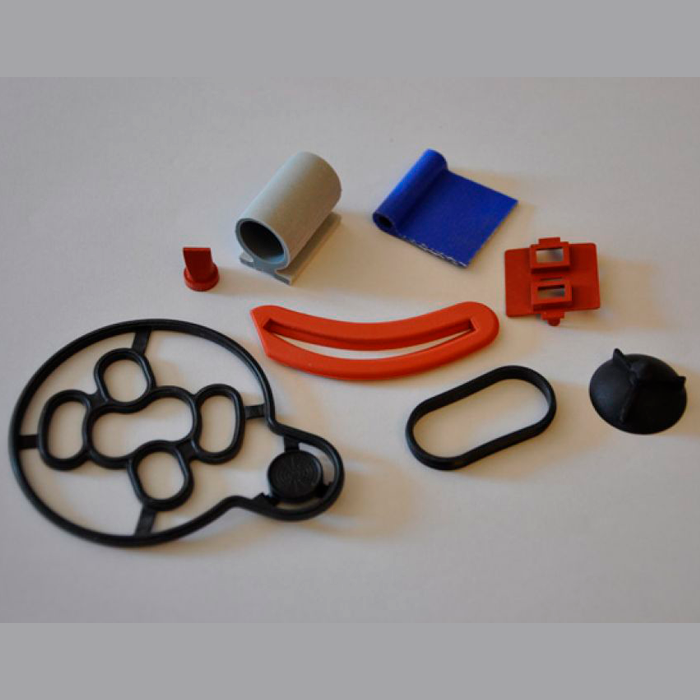

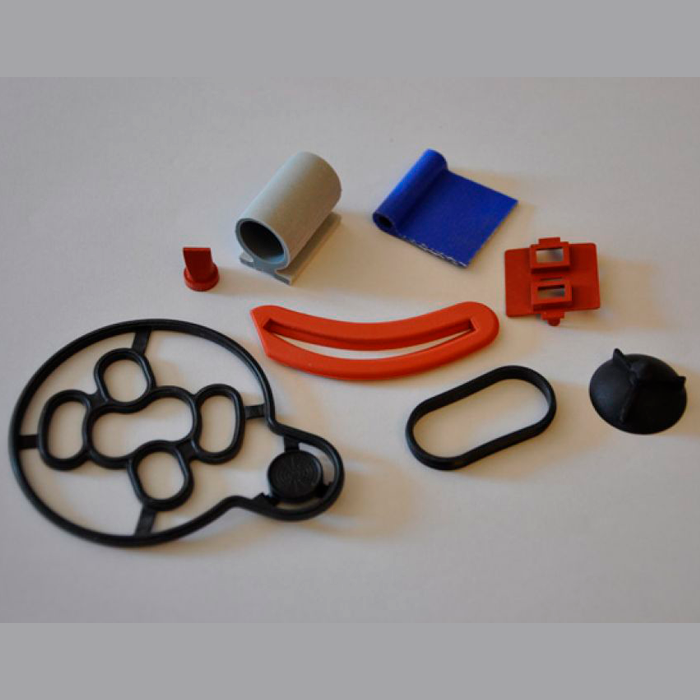

Medical device plastic injection molding is a method used in the manufacturing of products for healthcare and medical devices. It manufactured high-precision, durable, and sterile parts needed for medical, surgical, diagnostic, and disposable equipment.

Strict isolation, regulatory standards, ISO certifications, and biocompatible materials ensure that all components are safe and perform to the required standards in the treatment of patients.

Medical device plastic injection molding manufactures very accurate and dependable components used in medical equipment and devices that include, syringes and as far as diagnostic equipment.

Key Benefits:

This procedure is required to fulfil the current high demands in the field of healthcare, guaranteeing safety and promoting medical equipment innovations.

Biocompatible plastic parts molding is essential for parts that come into contact with the human body. Injection molding makes these materials safe and hygienic.

Key Features:

Biocompatible molding manufactures high-quality, reliable parts, ensuring patient comfort and safety.

Disposable medical component molding minimizes the chances of infection and helps in medical practices easier. Injection molding is perfect when manufacturing high volume disposable products which is also cost effective.

Applications:

This molding process ensures the consistency and cleanliness of medical components that require a high level of sterilization.

We believe in providing reliable, innovative, and cost-effective plastic injection molding solutions. Your trust allows us to deliver products that are precise, durable, and reliable.

Molded syringe and connector parts are very important medical instruments that require precision, reliability and safety. By using injection molding, these components are made with high quality and consistency.

Key Features:

Syringes and connectors are precisely molded thus enhancing security of the patient and effectiveness of the device.